Method and apparatus for measuring material thermal conductivity based on optical-modulated thermo-emission spectroscopy

A measurement device and thermal emission technology, applied in the direction of thermal development of materials, etc., can solve the problems of fast heat dissipation of low-dimensional structures, complicated experimental devices, unfavorable material/low-dimensional structure thermal characteristics measurement, etc., to achieve fast measurement without damage, detection Sensitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following is based on figure 1 and figure 2 The preferred embodiments of the present invention are given and described in detail to better illustrate the technical features and functional characteristics of the present invention, rather than to limit the scope of the present invention.

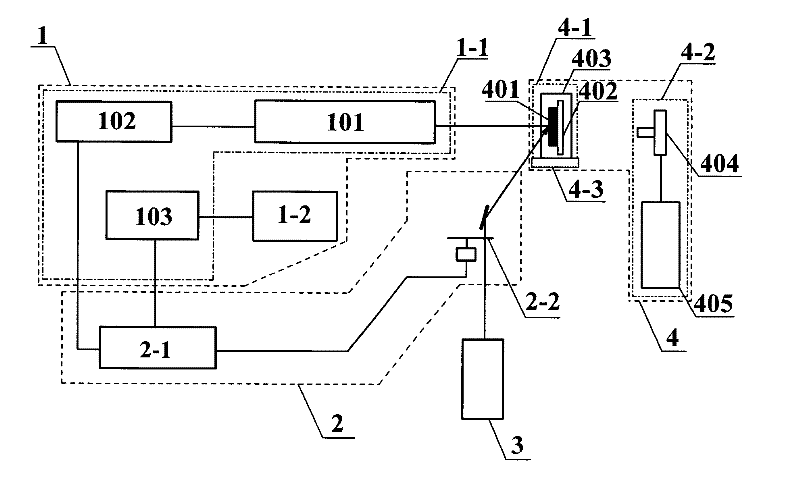

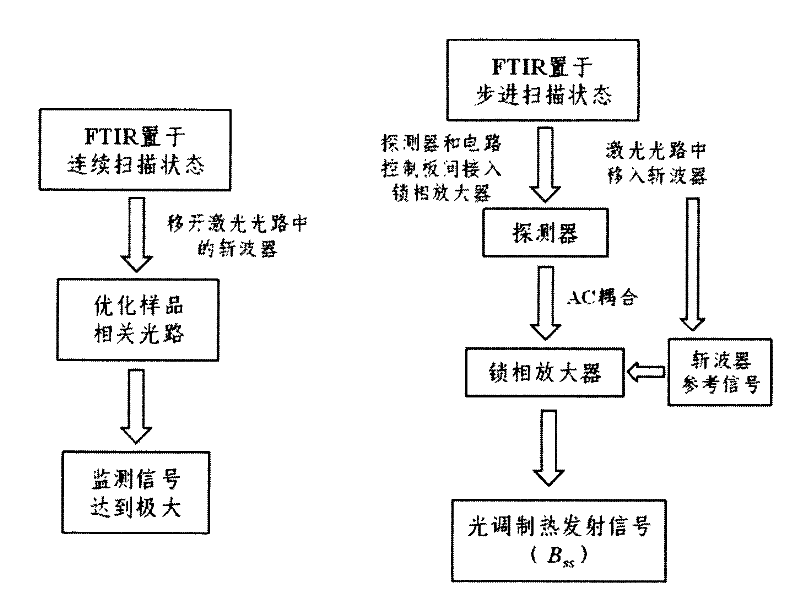

[0025] Specific implementations such as figure 1 As shown, the device for measuring the thermal conductivity of a material based on light modulation thermal emission spectroscopy includes - a lock-in amplifier 2-1 inserted in the light modulation device 2 between the spectrometer 1-1, the computer 1-2 and the base 4-3, And a chopper 2-2 is arranged on the path where the laser 3 is incident on the base 4-3, so as to form a modulated incident laser. More specifically, the device for measuring the thermal conductivity of materials by step-scanning light-modulated thermal emission spectroscopy of the present invention includes a Fourier transform infrared spectroscopy system 1, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com