windshield wiper equipment

A windshield, wiper technology, applied in the automotive field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

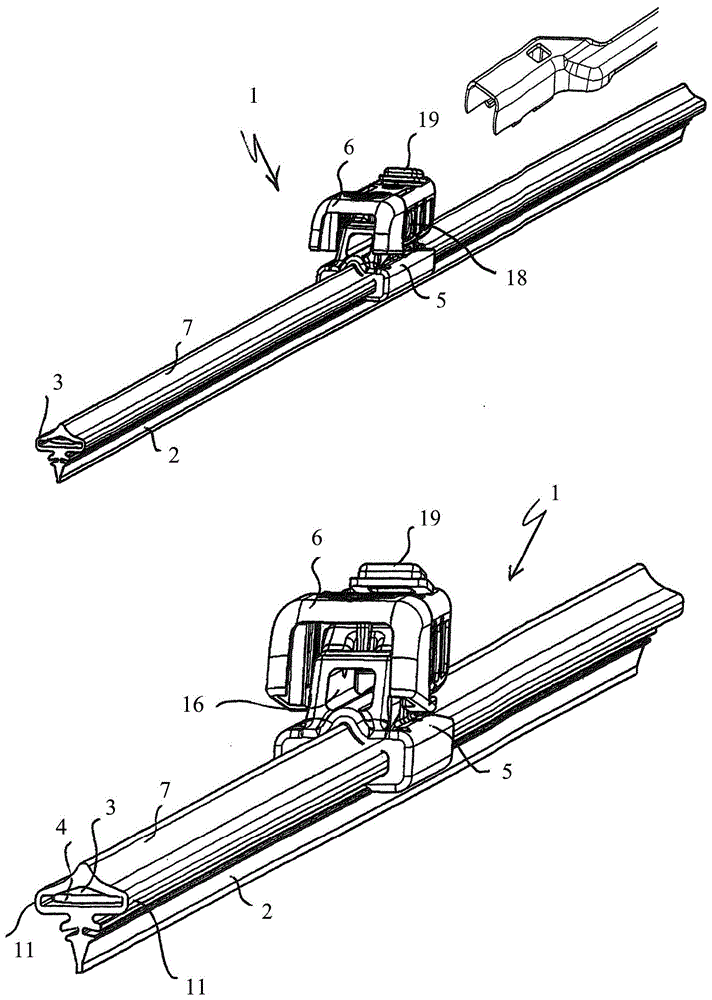

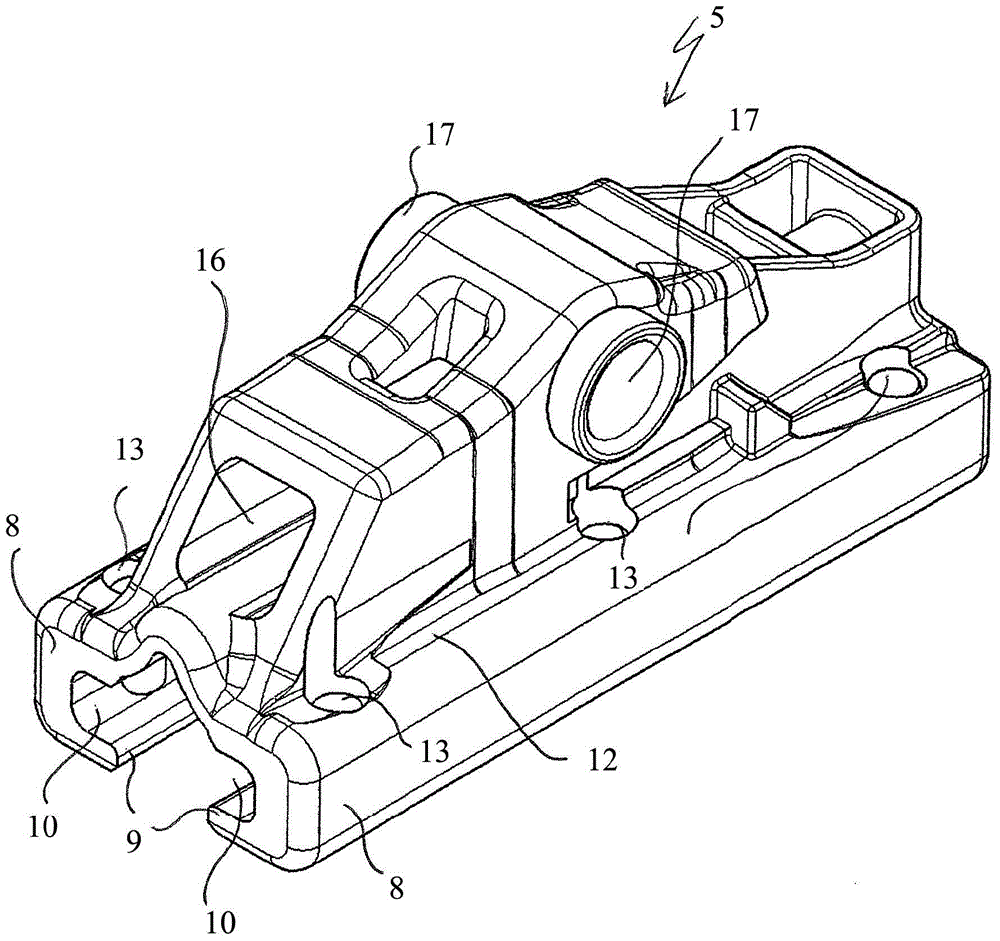

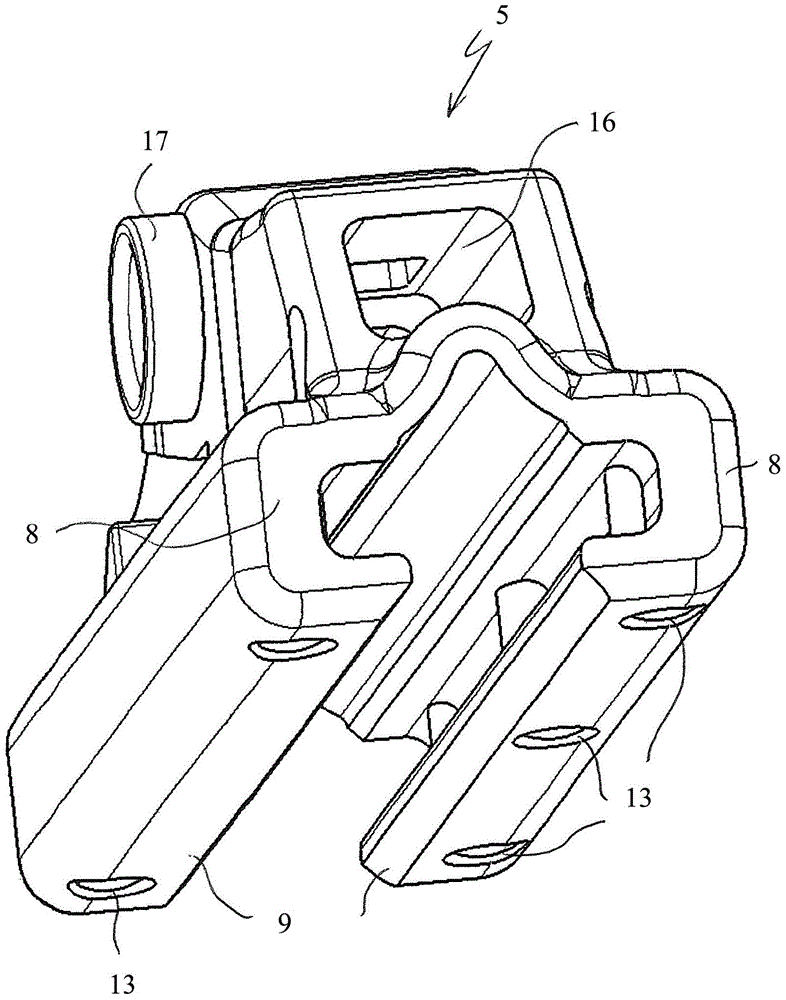

[0028] figure 1 A preferred variant of a windscreen wiper device 1 according to the invention is shown. The windscreen wiper device 1 consists of an elastomer wiper blade 2 comprising a central longitudinal groove 3 in which a longitudinal strip 4 made of spring strip steel fits (cf. Figure 5 , 6 and 7). In a way, said strip 4 forms a flexible carrier element for the rubber wiper blade 2 , which is thus biased in a bent position (the curvature of the operating position being the curvature of the windshield to be wiped). The windscreen wiper device 1 also consists of a metal or plastic connection device 5 for connecting the oscillating wiper arm to the connection device 5 by insertion of a coupling part 6 . The oscillating wiper arm is pivotally connected to the connection device 5 about a pivot axis near one end. According to the present invention figure 1 A preferred embodiment of the present invention comprises a spoiler or "air deflector" 7 which is made integrally wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com