Capping chuck assembly

A technology of chucks and components, applied in the direction of closures, pass-through elements, bottle/container caps, etc., capable of solving problems such as incorrect closing caps, application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] While the invention may be embodied in various forms, what is shown in the drawings and described below is a preferred embodiment of the invention, it being understood that the preferred embodiment of the invention is considered to be exemplary of the invention and is not intended to The invention is limited to the particular embodiment shown.

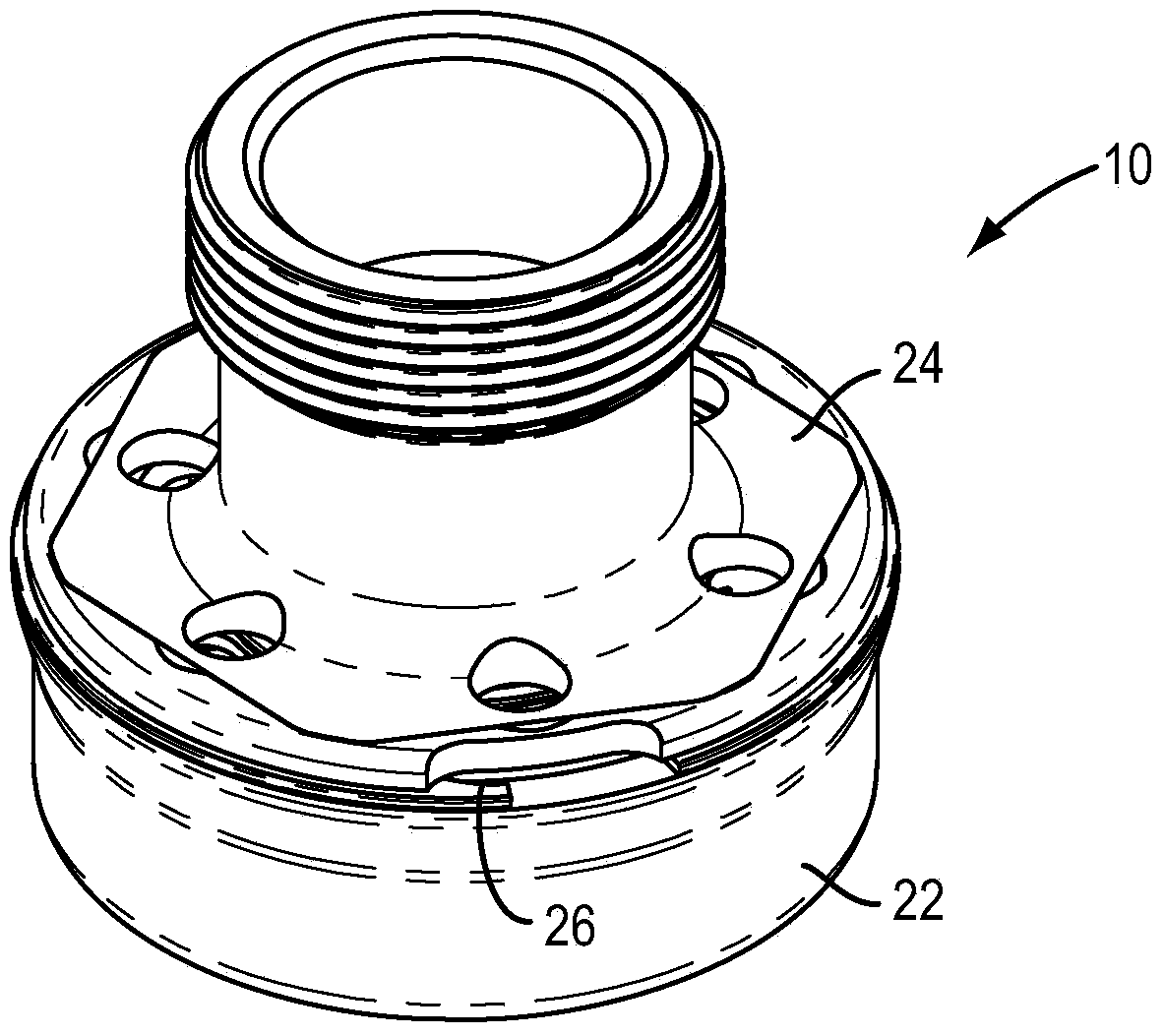

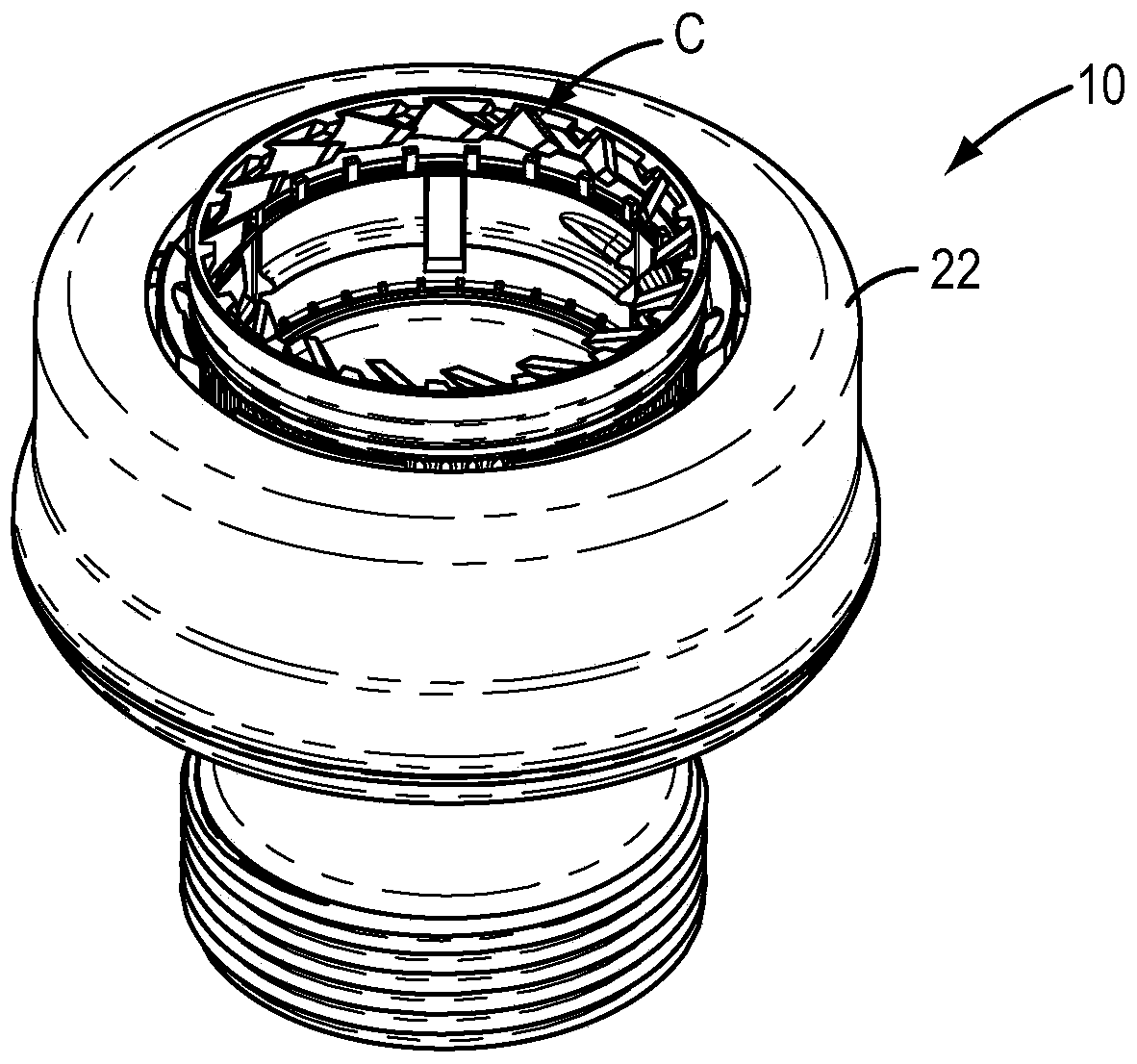

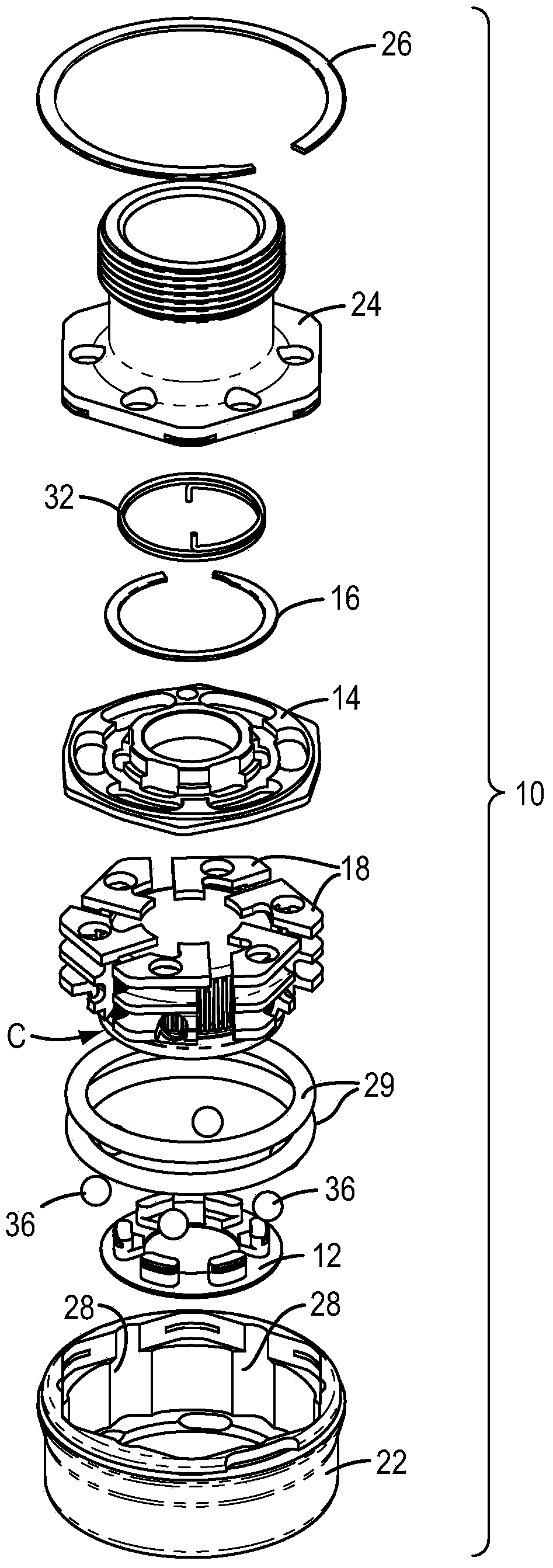

[0021] Referring now to the drawings, there is illustrated a capped chuck assembly 10 embodying the principles of the present invention. As will be appreciated by those skilled in the art, capping chuck assembly 10 is configured for use with high-speed automatic capping equipment for applying the threads of bottle caps to associated containers, such as on bottling machinery or the like. Filling operation. To this end, the capping chuck assembly is mounted into an associated rotary drive mechanism (not shown), whereby the capping chuck assembly is rotationally driven to rotationally apply the closure cap to the associated contai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com