Closure element

A technology of closing elements and closures, applied in the direction of pipe elements, engine elements, pipes/pipe joints/pipe fittings, etc., can solve problems such as hole damage, and achieve the effect of ensuring integrity, cheap production, and low weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

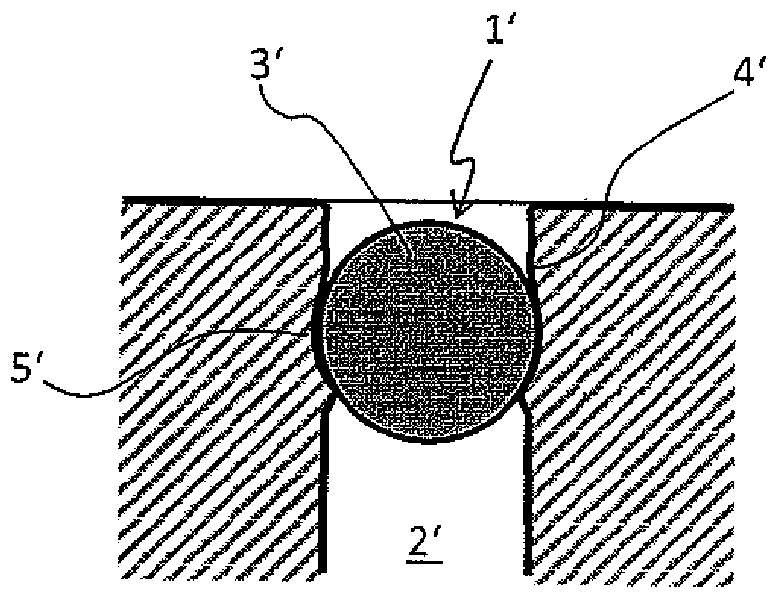

[0021] figure 1 The closure element 1' shown in is used to tightly close a hole 2' with a closure body 3' whose diameter is oversized relative to the diameter of the hole to be closed. By pressing the closure body 3' into the hole 2', the hole 2' is securely closed.

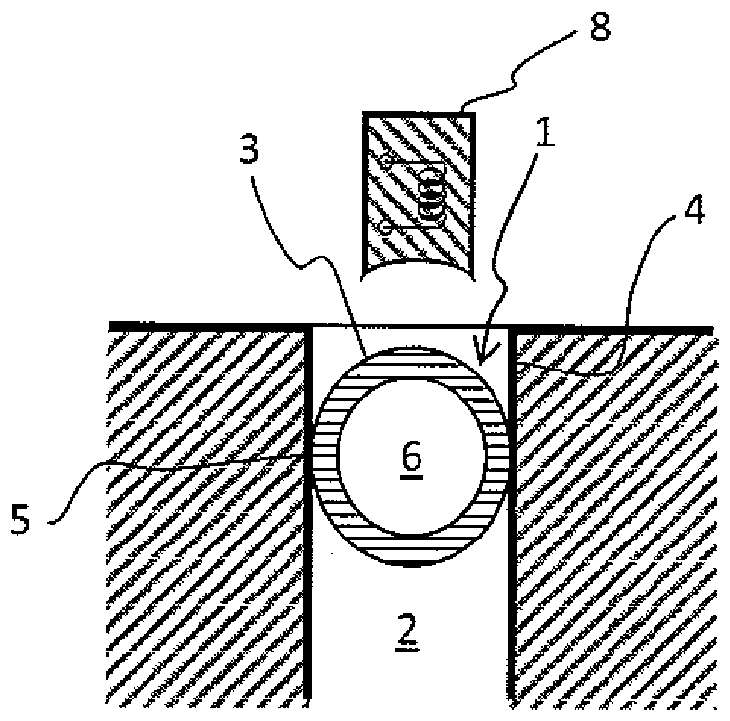

[0022] Such a closure element 1 is inserted into a housing with a hole 2 and a wall 4 , such as an engine housing of a motor vehicle, a hydraulic unit, a valve block or the like.

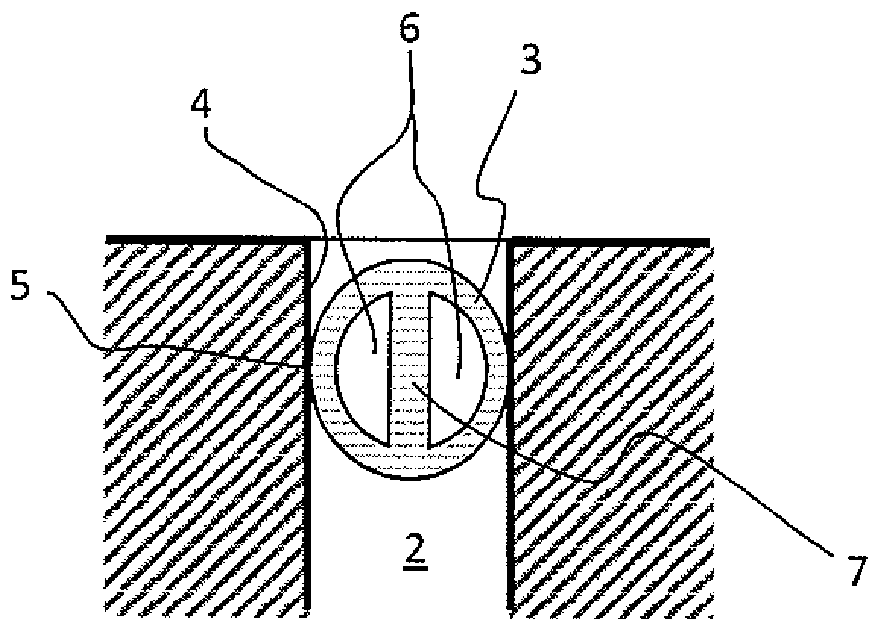

[0023] if possible from figure 2 As seen in , in the case of a conventional solid sphere 3', due to its excessive size, a high degree of radial pressure is exerted on the walls 4', 5' and also in the region of the hole into which the sphere is inserted, thereby causing the hole deformation or damage.

[0024] The closure element 1 according to the invention is characterized in that its also oversized closure body 3 is made in the form of a hollow body so that it can easily be elastically and / or plastically deformed. Thus, the rad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com