Urethane foam molding and method for manufacturing same

A foamed molded body and a manufacturing method technology, applied in the field of polyurethane foamed molded body, can solve the problems of accumulation, temperature rise, etc., and achieve the effects of high thermal conductivity, suppression of temperature rise, and excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0087] Next, an Example is given and this invention is demonstrated more concretely.

[0088]

[0089] [Example]

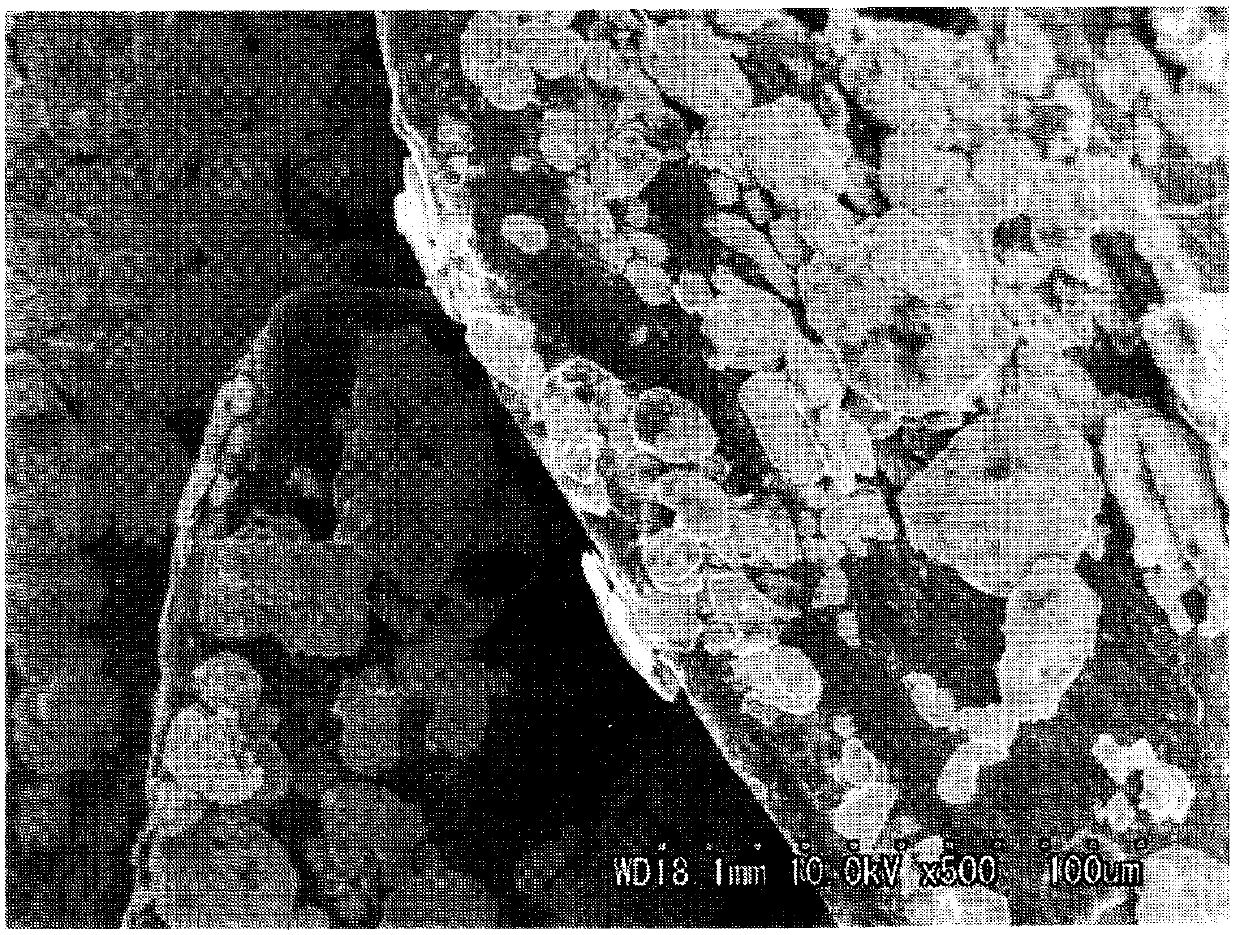

[0090] Two types of composite particles with different insulating inorganic particles were produced. First, thermally conductive particles of expanded graphite powder ("SYZR502FP" purchased from Sanyo Trading Co., Ltd., thermal conductivity 250W / m·K, average particle size 300μm), and magnetic particles of stainless steel powder (SUS410L, flaky, average particle diameter of 20 μm), alumina powder as insulating inorganic particles (“AL-43KT” manufactured by Showa Denko Co., Ltd., median diameter of 4.6 μm), and hydroxypropyl methylcellulose as a binder ( HPMC, "TC-5" manufactured by Shin-Etsu Chemical Co., Ltd.). The above-mentioned flaky stainless steel powder was produced by flattening spherical stainless steel powder ("DAP410L" manufactured by Daido Special Steel Co., Ltd., with an average particle diameter of 10 μm). That is, spherical stainless steel powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com