Egg laying duck cage of cage culture laying ducks

A technology for laying ducks and cages, which is applied in the poultry industry, poultry cages or houses, applications, etc., can solve the problems of increasing egg product processing and egg washing processes, large water consumption, and large workload of breeding personnel, so as to ensure egg production. Performance and egg quality, space saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

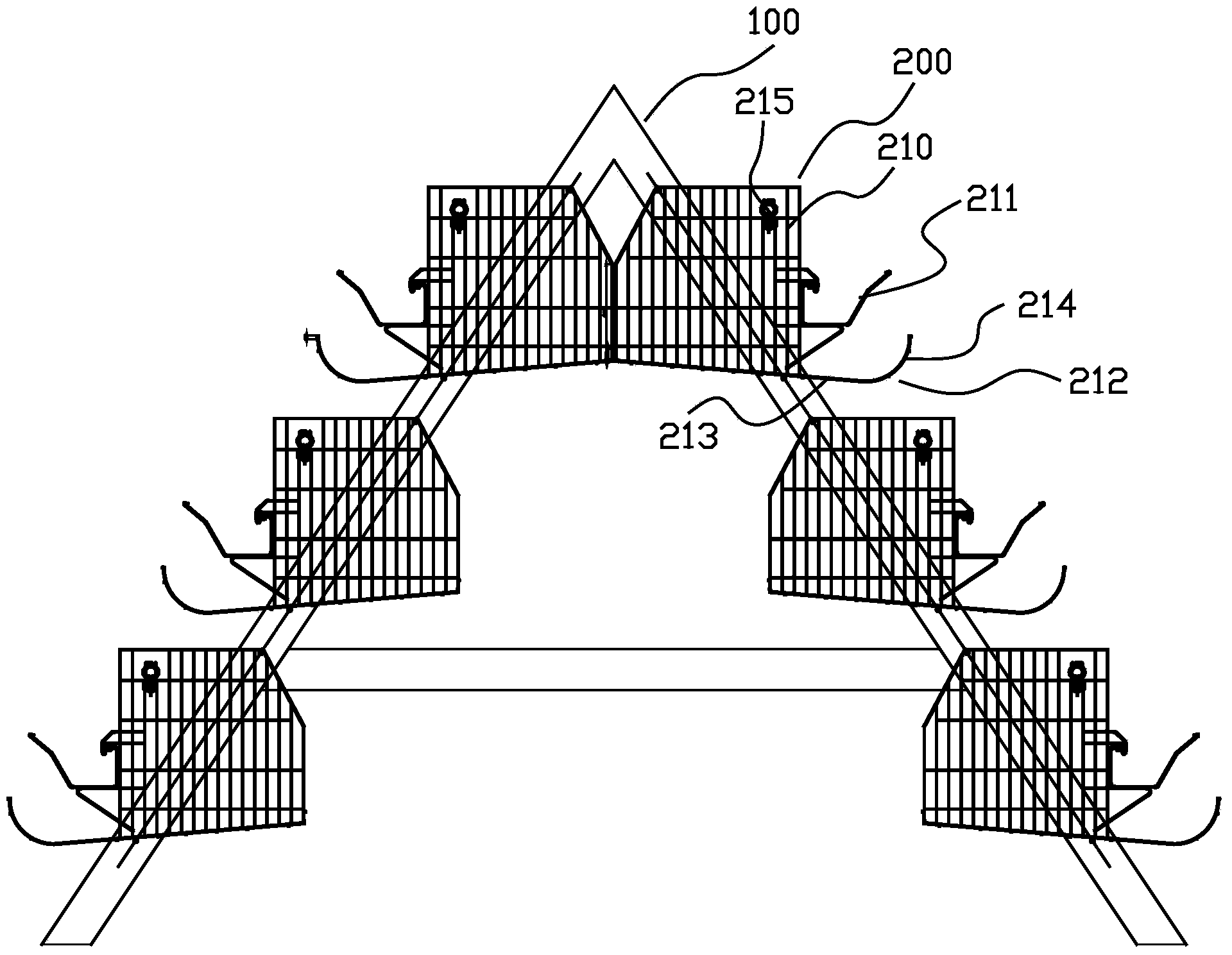

[0017] see figure 1 , a laying duck cage for laying ducks, comprising a bracket 100 and a cage body 200 arranged on the bracket 100, the bracket 100 includes more than two layers, and the left and right sides of the width direction of the bracket 100 are respectively provided with two production cages. Laying duck cages 210, each laying duck cage 210 includes more than two laying duck cages 210 connected to each other, and the side walls of the laying duck cages 210 facing the outside are provided with cage doors, and at the same time, there are cage doors on the outside of the laying duck cages 210. Feed troughs 211 are respectively arranged below, and an automatic feeder for automatically feeding feed troughs 211 is also included. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com