Novel machine disposable shoe covers and shoe cover connected roll

A one-time, shoe cover technology, applied in footwear, applications, clothing and other directions, can solve the problems of poor coordination of shoe overshoe machines, unreasonable structure, easy damage to shoe covers, etc., to facilitate mechanized automatic production, good coordination , The product structure is reasonable and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

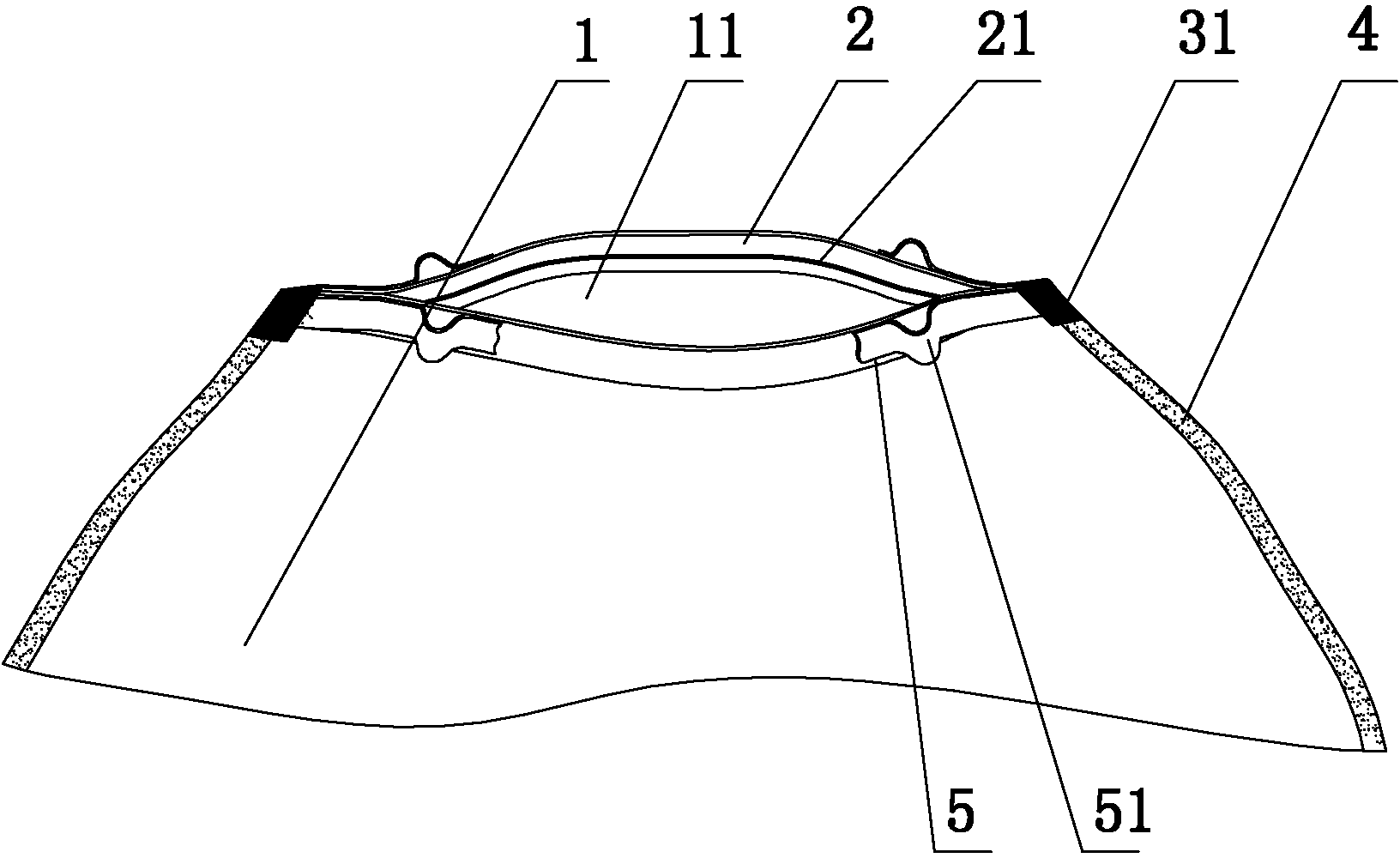

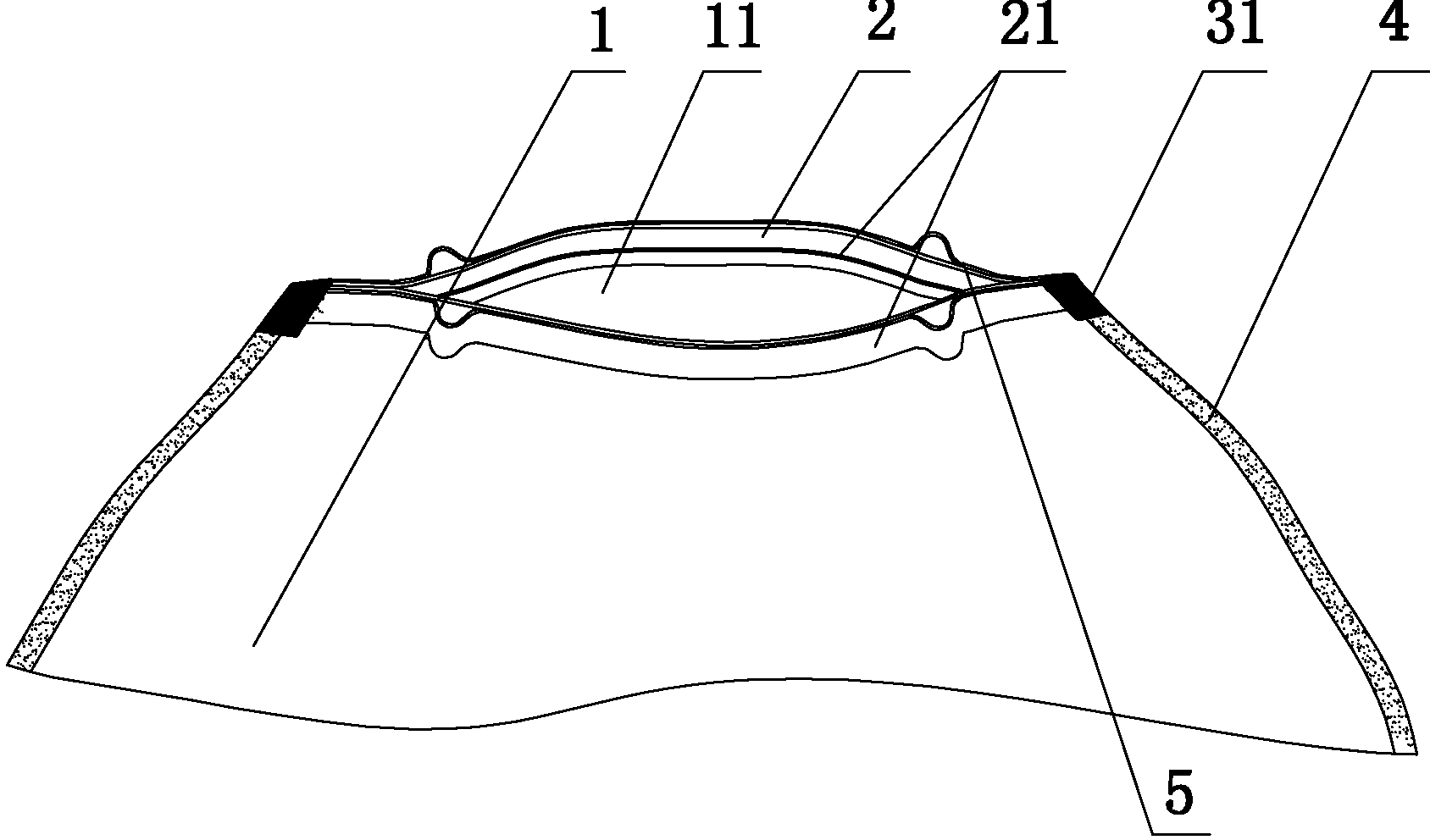

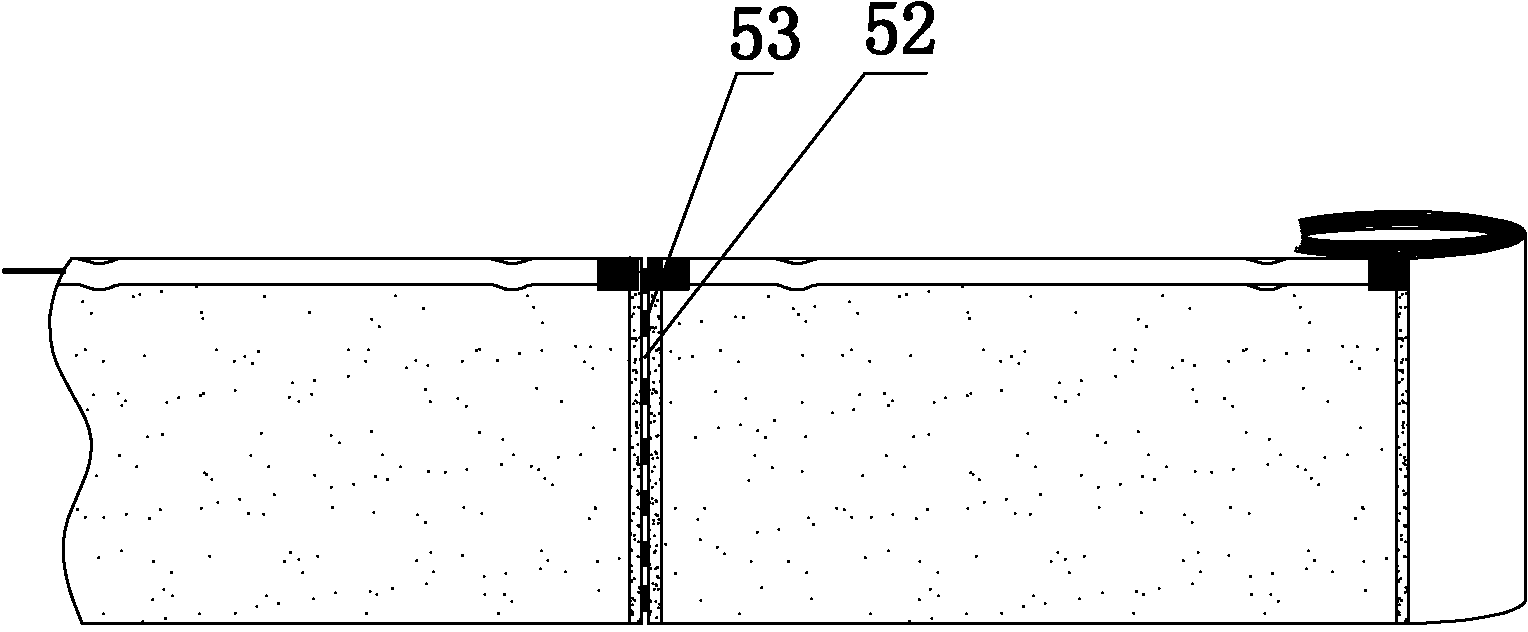

[0020] figure 1 It is a schematic diagram of a preferred structure of the present invention. It comprises a shoe cover bag 1 and an elastic band 21. The shoe cover bag 1 adopts plastic films such as PE or PP, and its front and rear sides are heat-sealed trimmings 4. Elastic band 21 is welded in the curling 2 at the elastic opening 11 of the shoe cover, and a non-woven fabric fixing piece 31 is welded at the front end and the rear end of the elastic opening of the shoe cover, and the two sides of the shoe cover bag 1 near the elastic opening A plastic drawstring 5 with a protrusion 51 is pasted and welded. The plastic drawstring is parallel to the elastic mouth 11 edge of the shoe cover bag, and the inner surface except the protrusion 51 on the plastic drawstring 5 is pasted and welded together with the shoe cover bag outer surface.

[0021] In each shoe cover, there must be more than one protrusion 51, preferably 4, wherein two protrusions 51 are provided on the coplanar pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com