Platform pressing mold for steel pipe surfaces

A surface pressing and pressing platform technology is applied to a pressing platform mold for a steel pipe surface pressing platform. field, it can solve the problems of low process efficiency, unreasonable structure, and low yield of molds and pressing platforms, and achieve the effects of high yield, reasonable structure, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below through specific examples.

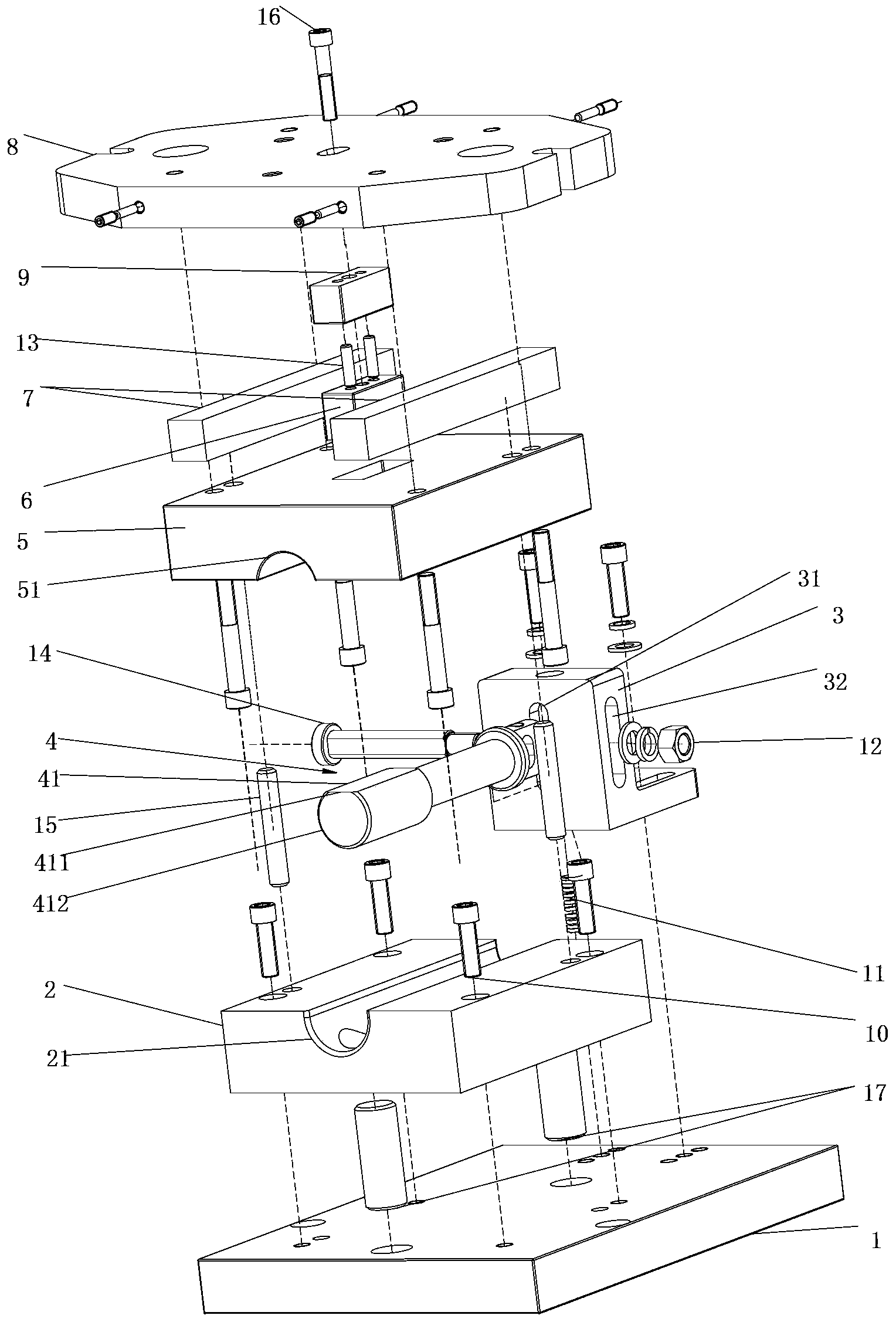

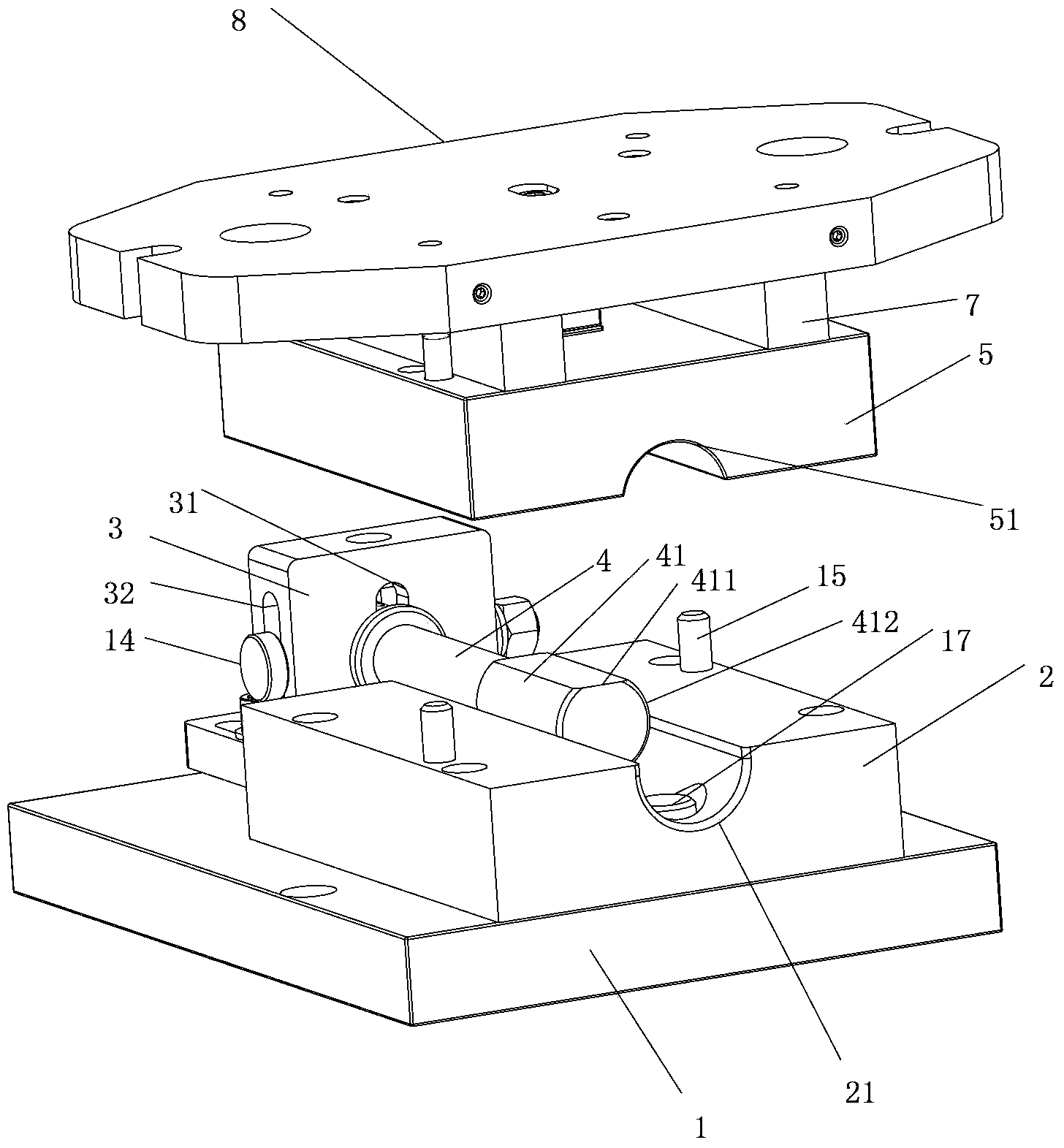

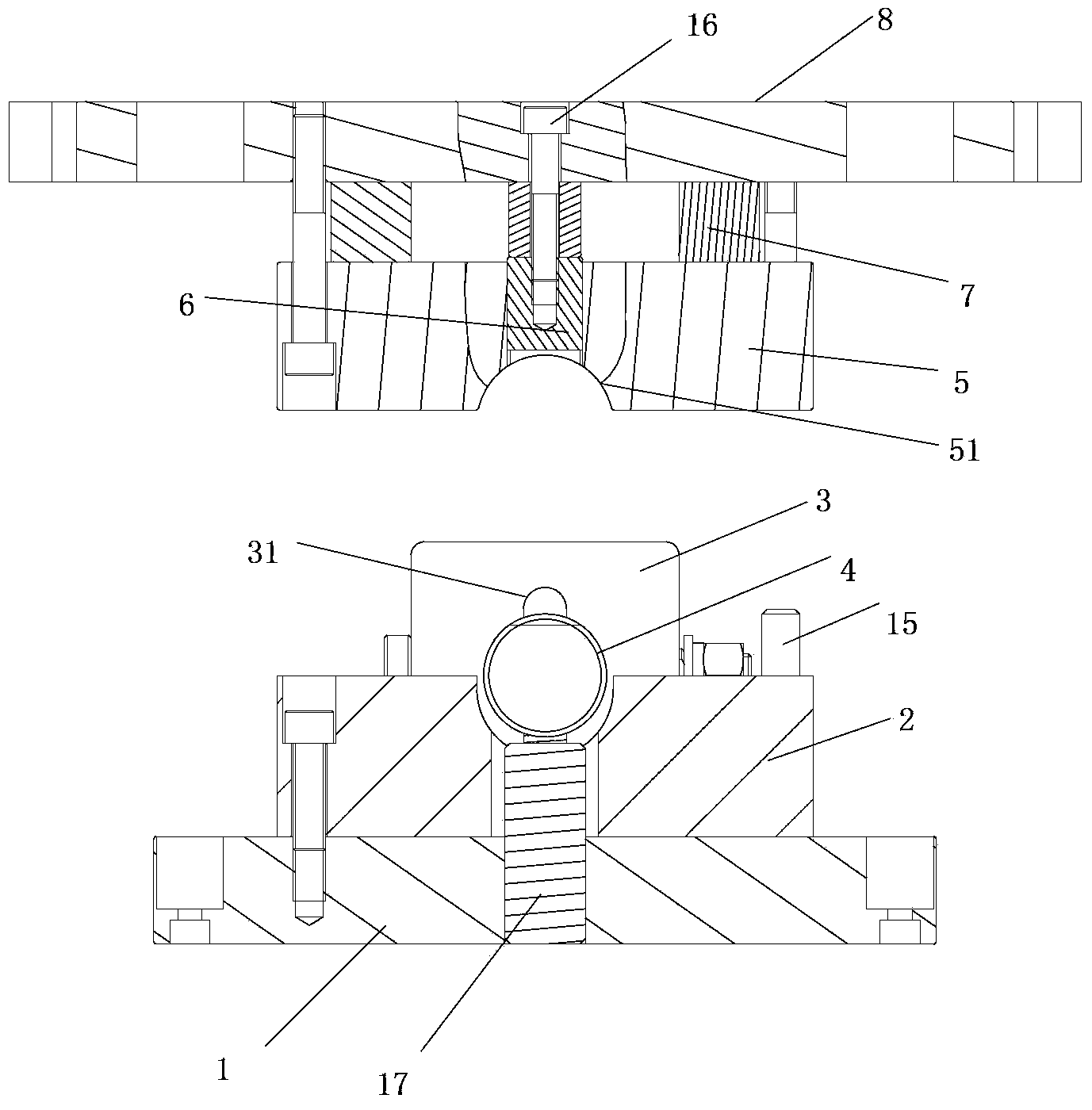

[0018] Such as Figure 1 to Figure 3 As shown, a steel pipe surface pressing platform mold, including a base 1, a lower mold 2, an upper mold 5, a mandrel assembly, an upper template 8, a pressure head 6, and the lower mold 2 is fixed by four fixing bolts 10 Fixed on the base 1, the upper surface of the lower mold 2 is provided with an arc-shaped lower mold cavity groove 21; wherein the arc-shaped lower mold cavity groove 21 is preferably a superior arc, and correspondingly, it will be described later The upper mold cavity groove 51 of the upper mold cavity is preferably an inferior arc, so that even if the upper mold 5 is retracted and reset, it is also convenient to hold the steel pipe tightly. The lower mold 2 is equipped with two positioning pins 15, and the corresponding upper mold 5 Position is provided with two positioning holes, is convenient to upper mold 5 and lower m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com