Cam type pressing device

A pressing device, cam-type technology, applied in positioning devices, workpiece clamping devices, clamping and other directions, can solve the problems of difficult and inconvenient reversible fast pressing of the pressing plate, and achieve a wide range of applications and reasonable structural design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

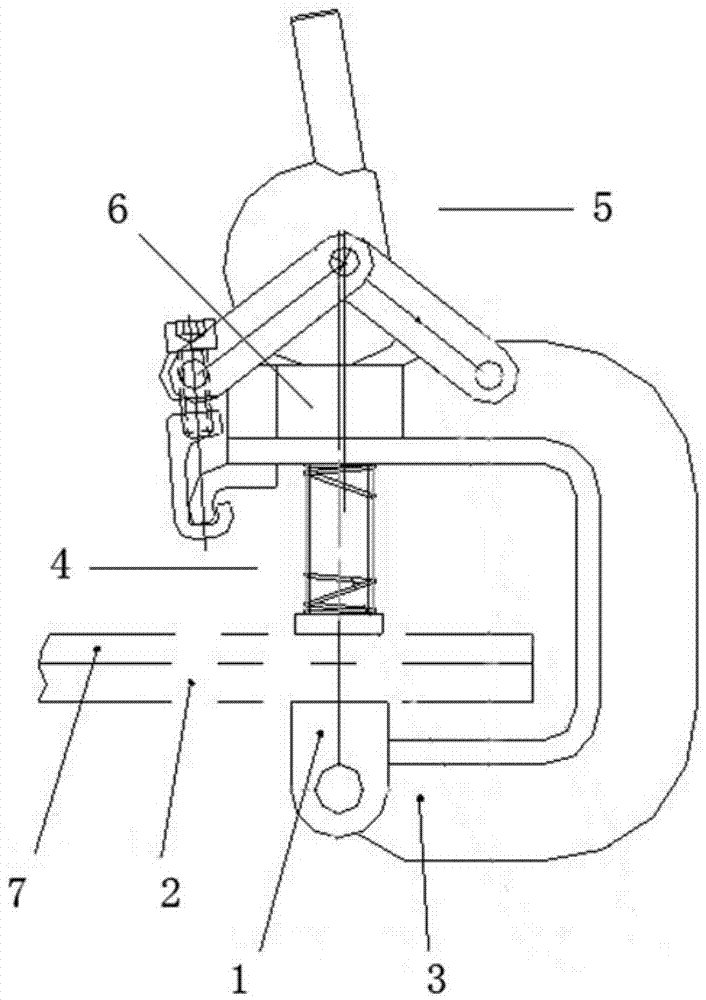

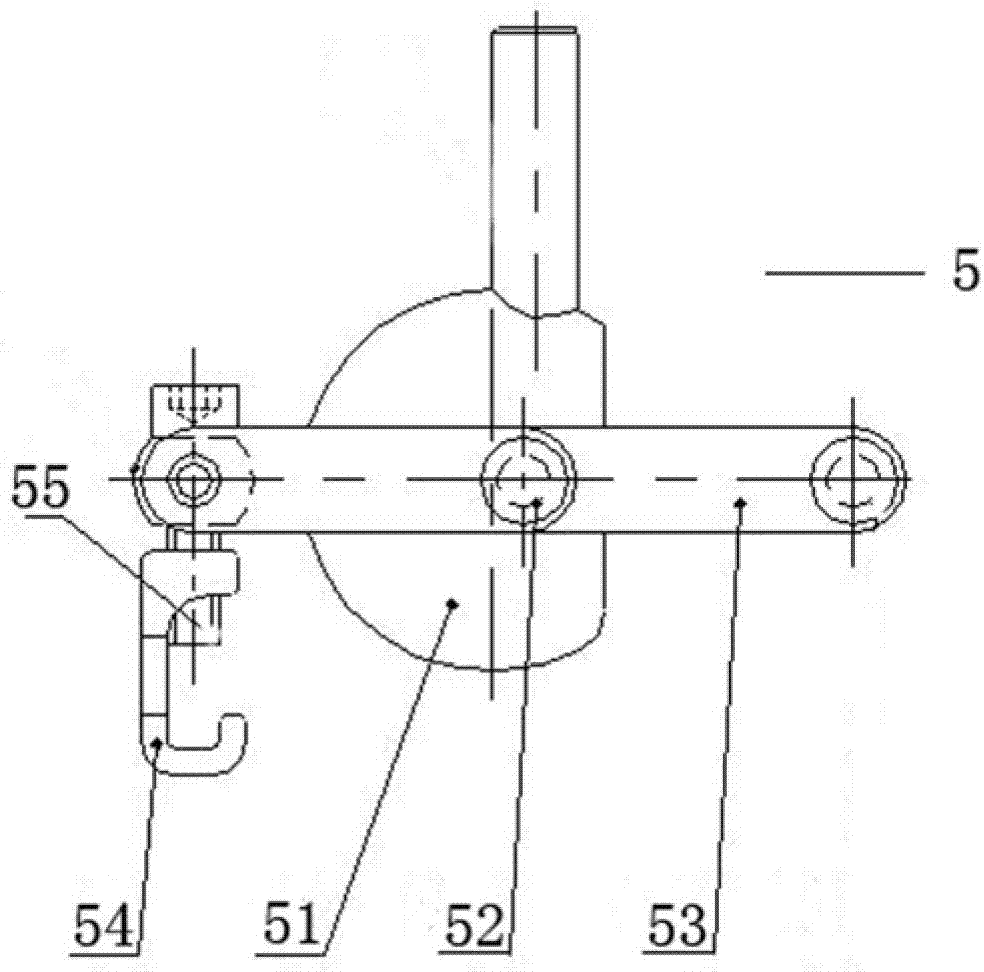

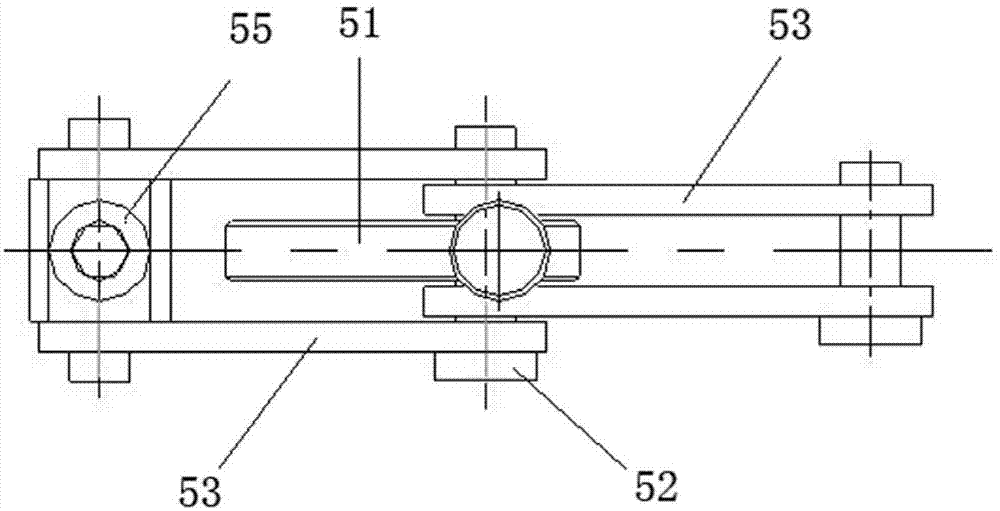

[0022] refer to figure 1 , Figure 4 , Figure 5 and Figure 6 , a cam-type pressing device of the present invention, comprising: a mounting seat 1, an inverted "U"-shaped pressing plate main body 3 connected with the mounting and fixing seat 1 with a pin shaft, and a push plate body 3 vertically passing through the top of the pressing plate main body 3. A rod mechanism 4, and a cam clamping mechanism 5 arranged on the top of the pressing plate main body 3 and above the push rod mechanism 4. Wherein, the installation and fixing seat 1 is used to connect with the fixture 2, which can be welded, screwed or riveted, and the bottom surface type of the installation and fixing seat 1 can also be appropriately improved according to needs; The pressing plate body 33 is composed of one end of the pressing plate main body 3 pinned to the mounti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com