Multifunctional compound machine

A compound machine and multi-functional technology, applied in the direction of lamination device, lamination auxiliary operation, lamination, etc., can solve the problem of single compound function of the compound machine, and achieve the effect of simple structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

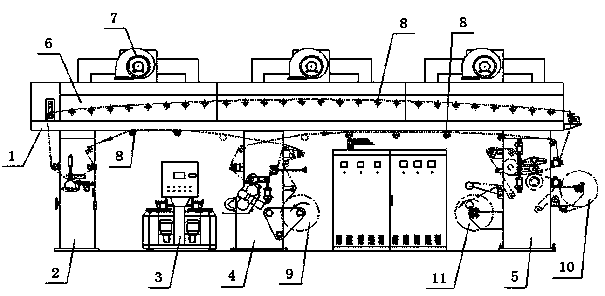

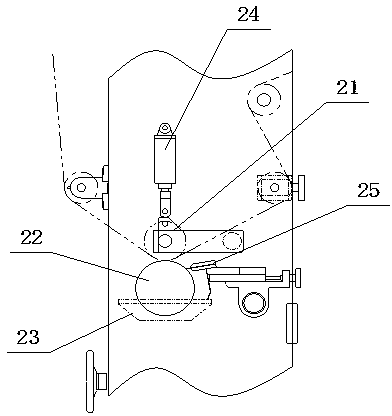

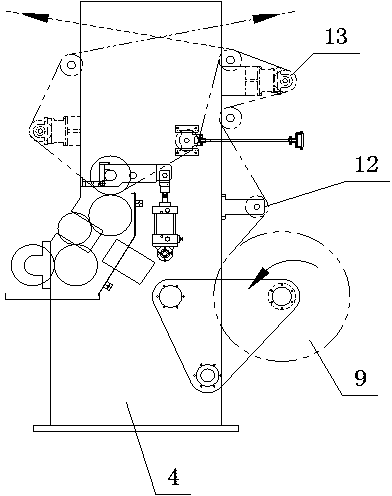

[0020] see Figure 1 to Figure 4 As shown, a multifunctional composite machine includes a screen coating mechanism 2, a glue mixer 3, a coating mechanism 4 and a composite mechanism 5 arranged sequentially from left to right under the frame 1, and a drying mechanism is set above the frame 1. device, the drying device includes a drying channel 6 and a dryer 7 installed on the drying channel 6, the drying channel 6 is divided into three interconnected sections, and the drying channel 6 is provided with a number of rollers 8. The rollers 8 are equidistantly arranged on an arc, the glue mixer 3 is connected with the coating mechanism 4 and provides solvent-free glue, the first unwinder 9 is installed on the coating mechanism 4, and the second The unwinder 10 and the winder 11 are provided with several rollers 8 between the first unwinder 9 and the net...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com