Continuous Printing Device for Large Textile Patterns

A textile and printing technology, applied in printing, printing presses, rotary printing presses, etc., to achieve the effect of continuous rotary screen printing of large patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific technical solutions of the present invention will be further described below with reference to the accompanying drawings, so that those skilled in the art can further understand the present invention, without restricting their rights.

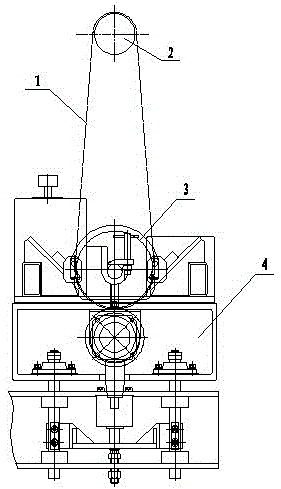

[0009] Reference attached figure 1 , A continuous printing device for large textile patterns, including a nickel mesh cylinder 3 mounted on the frame 4. The nickel mesh cylinder 3 is equipped with an automatic slurrying device. There is no more pattern on the rotary screen printing nickel mesh cylinder 3. The nickel mesh drum 3 only plays a role of leakage, support and transmission. The printing color separation pattern is made into a printing mesh belt 1, which is set on the synchronously driven nickel mesh drum 3. A driven roller 2 supporting the printing mesh belt 1 is provided above the nickel mesh drum 3. The driven roller 2 is The roller body can be rotated freely, and the printing mesh belt 1 is tensioned, and the tensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com