A construction method for the installation and construction of well-shaped beams in comb-shaped slideway in deep water

A construction method and technology of well-shaped beams, which are used in transportation and packaging, ships, dry docks, etc., can solve the problem that the high-precision installation requirements of rails on the well-shaped beams of slideways cannot be met, the elevation and axis alignment are difficult to control, and the construction risk is high. and other problems, to achieve the effect of high degree of mechanized operation, smooth implementation of guarantee, and high scientific and technological content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

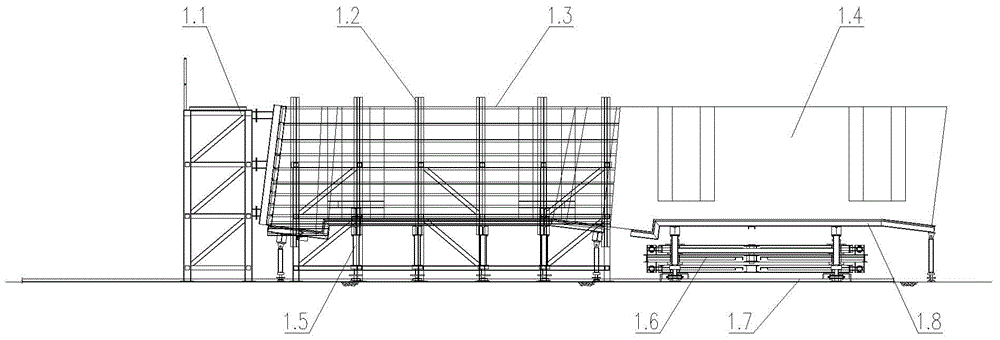

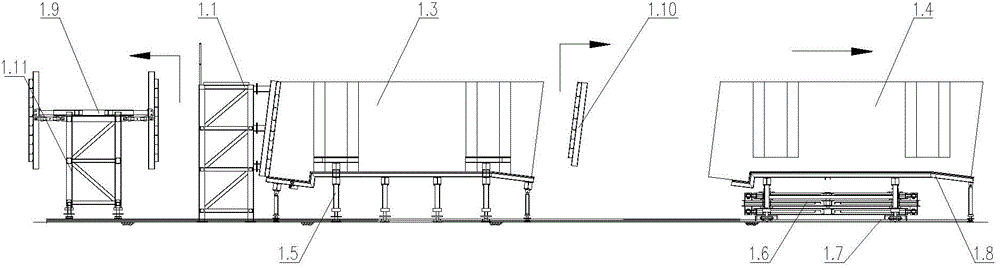

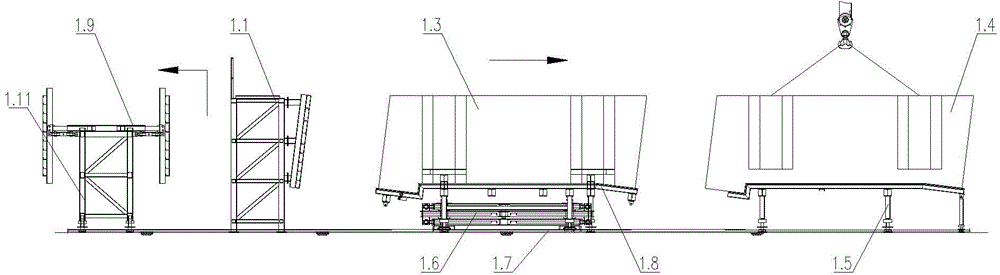

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0042] The construction method of sliding to the well-shaped beam described in the present invention is a construction method based on short segment matching prefabrication, rolling pre-assembly and underwater installation, which includes the following steps:

[0043] 1) Short-segment matching prefabrication of the well-shaped girder of the slideway:

[0044] a. On the prefabricated pedestal, pour the first well-shaped beam section first. After the concrete strength meets the design requirements, move the first well-shaped beam section to the matching pedestal, and use the first well-shaped beam section as the matching beam Section, the front end of the first well-shaped beam section is used as the end mold of the second well-shaped beam section to be poured, and the second well-shaped beam section is poured on the prefabricated pedes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com