Differential feeding mechanism for automatic directional sequencing

A technology of feeding mechanism and hopper mechanism, which is applied in the direction of conveyor objects, transportation and packaging, etc. It can solve the problems of weak vibration of the vibrating plate, uneven table top, lack of hardness, etc., and achieve low equipment structure requirements, easy machine adjustment, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

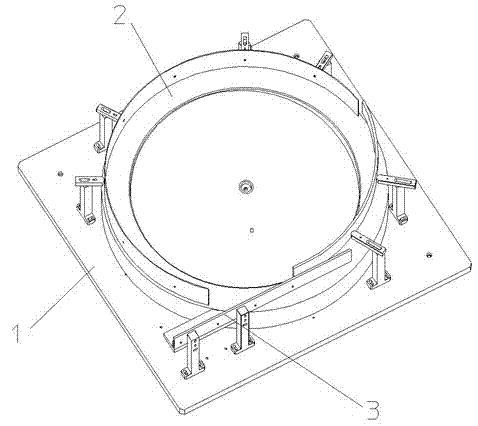

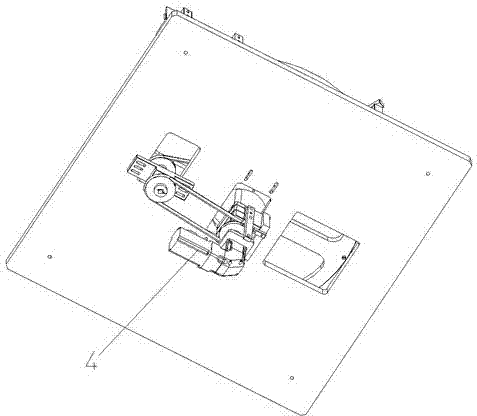

[0035] Such as figure 1 and figure 2 As shown, the automatic directional and sorting differential feeding mechanism is mainly used for automotive connector plastic products, including a mounting base plate 1 with mounting holes, which is connected to the mounting base plate and can perform differential rotation and material selection and has a discharge The hopper mechanism 2 at the mouth is installed on the installation base plate and corresponds to the discharge channel mechanism 3 of the discharge port of the hopper mechanism, and the servo motor rotation mechanism 4 is arranged on the lower side of the installation base plate and enables the hopper mechanism to realize differential rotation. Among them, the specific structure of each institution is as follows:

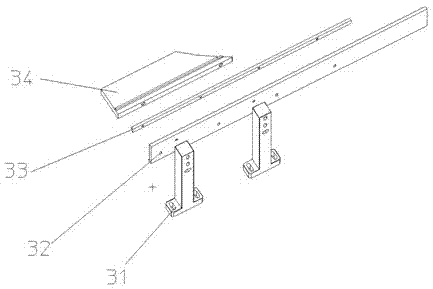

[0036] Such as image 3 As shown, the discharge channel mechanism is mainly used for feeding and discharging the plastic products after directional sorting by the hopper mechanism, which specifically includes tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com