Towline winch with brake structure

A technology of towing winches and brake bands, which is applied in the field of towing winches and marine equipment, which can solve problems such as safety accidents, rollers not positioned and rolling, danger, etc., and achieve the effect of reducing wear and friction and ensuring installation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

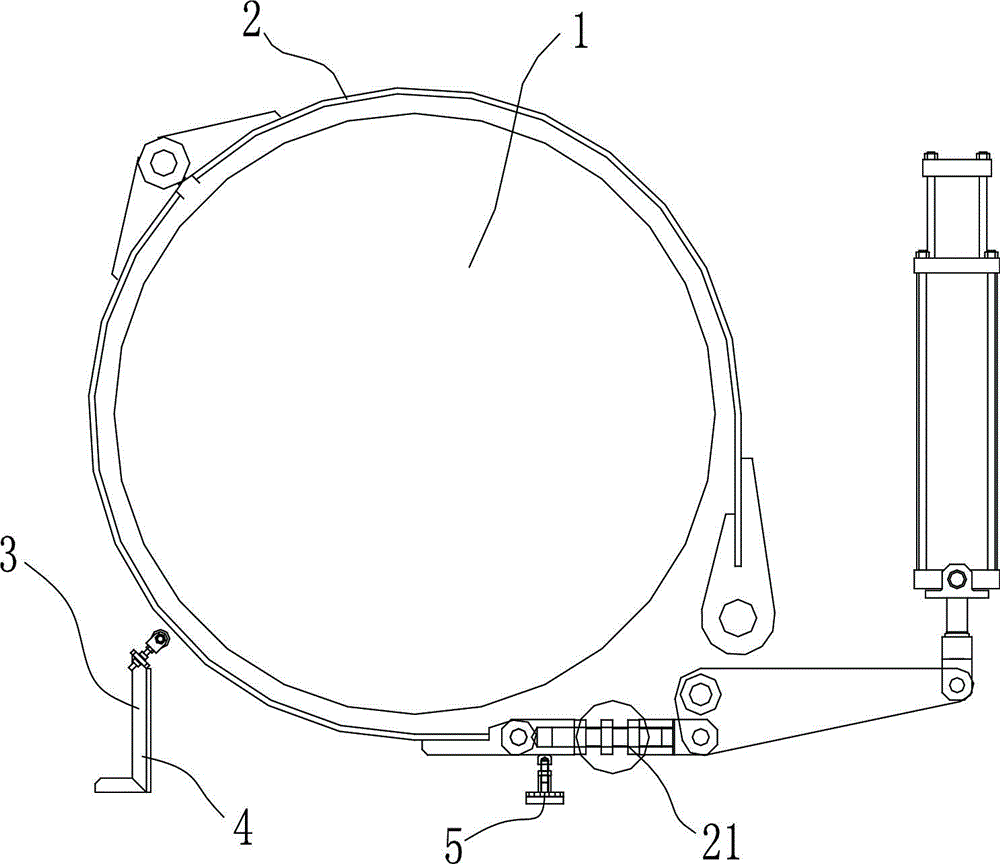

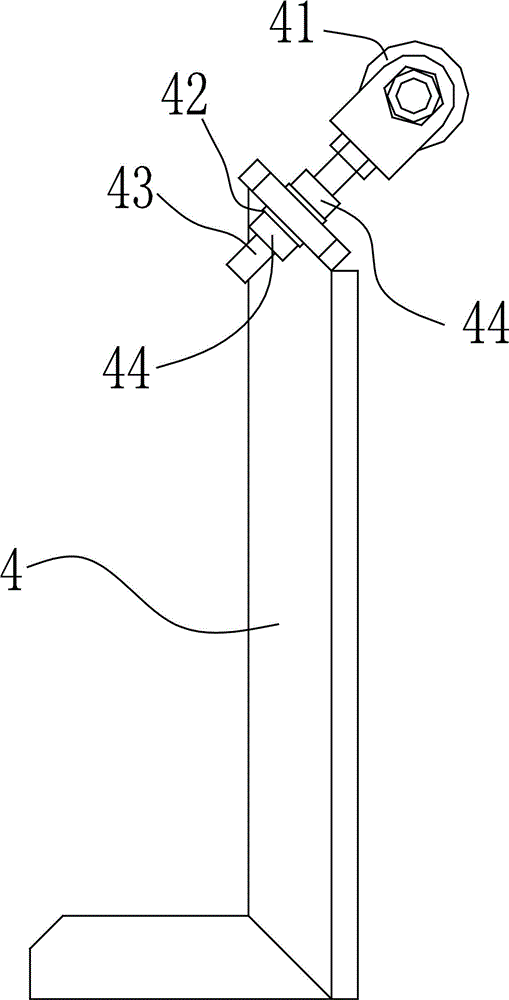

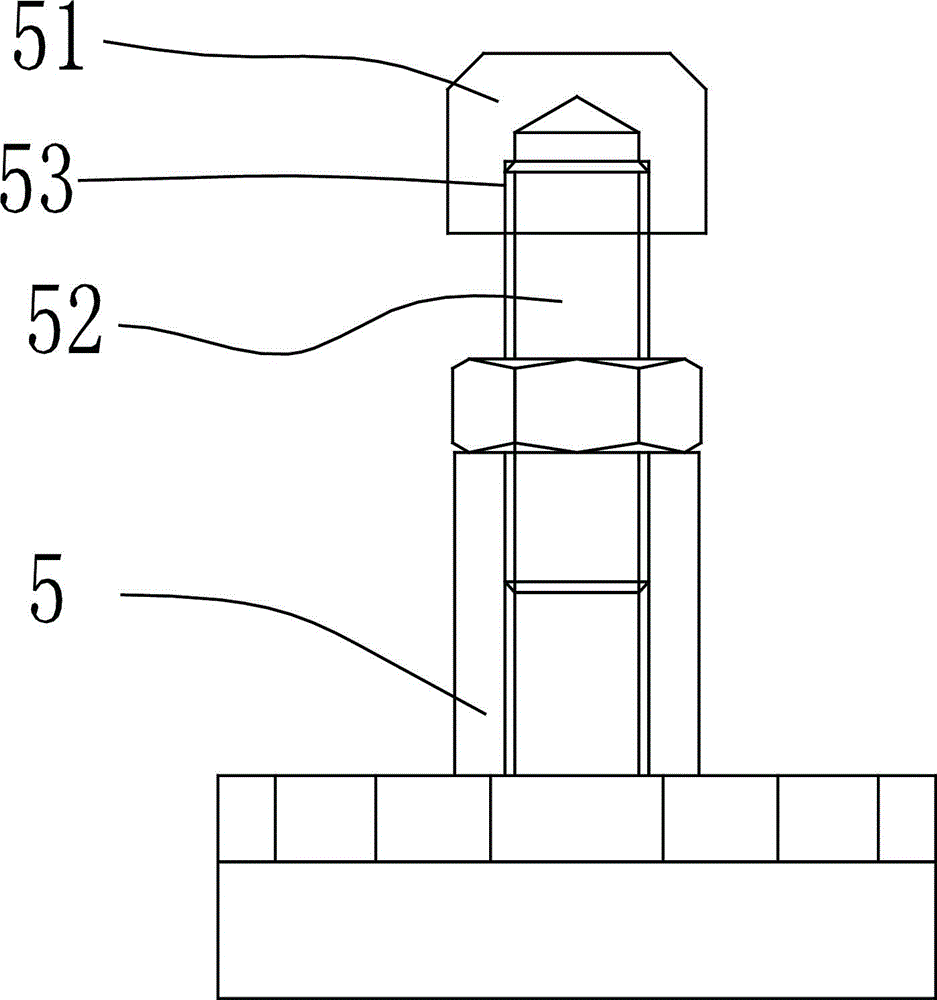

[0020] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1 to Figure 6 , a tow cable winch with a brake structure, including a drum 1, a brake band 2 is arranged on the outside of the drum 1, a jacking device 3 is arranged below the brake band 2, and the jacking device 3 includes a first bracket 4, the A pulley 41 is arranged on the first bracket 4 . When the brake band 2 is about to be loosened, the bottom of the brake band 2 will touch the jacking device 3 so that the top of the brake band 2 can be separated from the drum 1 very quickly, preventing the top of the brake band 2 from being close to the drum 1 due to the influence of its own gravity. Difficult to disengage, the pulley 41 is set to reduce the friction between the jacking device 3 and the brake band 2, and reduce wear. The drum 1 is also provided with a ratchet 11, and also includes a clamping block 6 that cooperates with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com