Pulse water distributor

A technology of pulse water distributor and water-sealed tank, which is applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., and can solve the problems of sludge loss, entrainment, excessive oxygenation, etc. , to achieve the effect of reducing air entrainment, improving pulse efficiency and reducing sludge loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

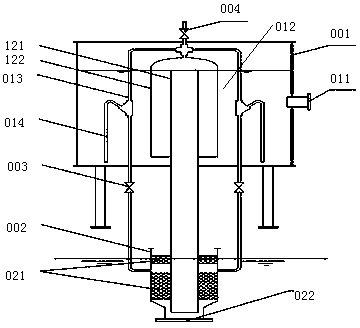

[0012] A pulse water distributor, comprising a cylinder body 001, a water inlet pipe 011 set on the cylinder body 001, a central water outlet pipe 012 arranged in the cylinder body 001, a vacuum tube 013, and a water seal tank 002 is added under the cylinder body 001, The central outlet pipe 012 is composed of inner and outer pipes (121, 122), the outer pipe 122 is a sealed chamber, the upper end of the inner pipe 121 extends into the chamber of the outer pipe 122, and the upper port is located near the chamber of the outer pipe 122 At the top, the lower end of the inner tube 121 passes through the bottom of the cylinder 001 vertically downwards and extends into the water-sealed tank 002. One end of the vacuum tube 013 is connected to the top of the outer tube 122, and the other end extends out of the bottom of the cylinder 001 Connected with the water seal tank 002, the water seal tank 002 is provided with a multi-layer grid plate 021, and the vacuum tube 013 is also provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com