Formula and manufacturing method of corrosion resistant concrete tubular pile

A concrete pipe pile and corrosion-resistant technology, applied in the field of pipe pile manufacturing, can solve problems such as accidents, threats to life and property, collapse of buildings and bridges, etc., and achieve the effects of life and property safety protection, reasonable material matching, and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

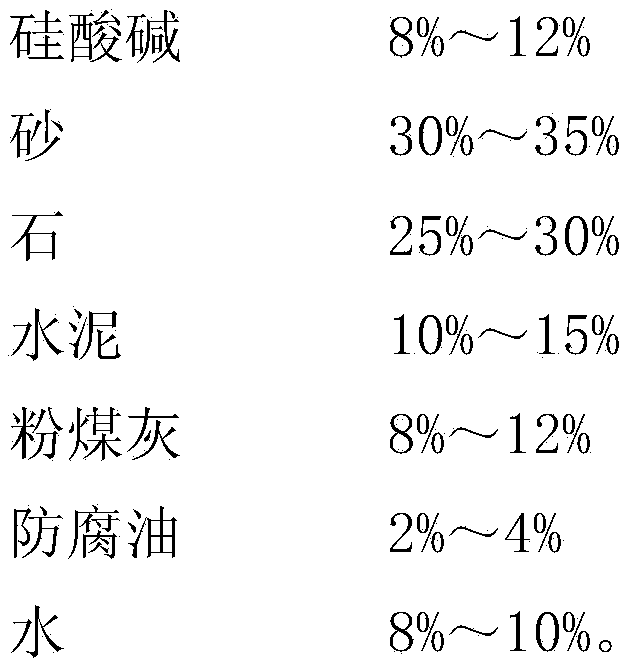

[0021] A formula for corrosion-resistant concrete pipe piles, the formula includes silicate, sand, stone, cement, fly ash, anti-corrosion oil and water, and the mass percentage of each component is as follows:

[0022]

[0023] The anti-corrosion oil is prepared by mixing tung oil and copper oleate in a ratio of 1:3.

[0024] A preparation method of a corrosion-resistant concrete pipe pile formula, the preparation method comprising the following steps:

[0025] 1) Preliminary mixing. After weighing sand, stone and cement according to a certain proportion, put them into the mixer for mixing, take a certain amount of water, and add water to the mixer while stirring;

[0026] 2) Measure a certain amount of water and put it into the container, the water temperature is controlled at about 30°C, put the silicate into the container, and stir until it is completely dissolved;

[0027] 3) Pour the liquid in step 2) into the mixer in step 1), and stop stirring after stirring for 30-...

Embodiment 2

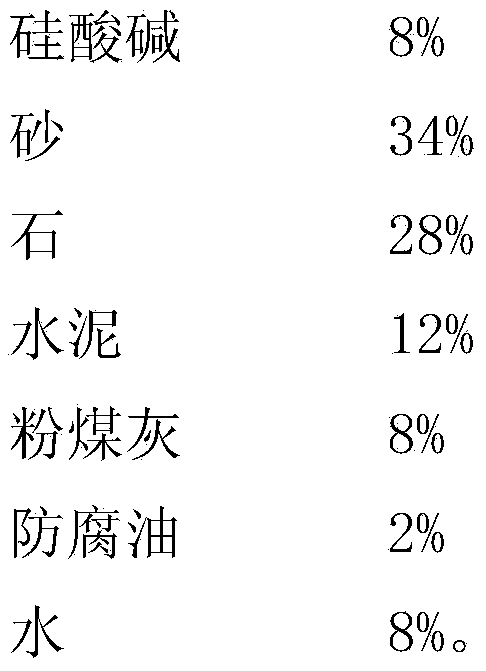

[0031] A formula for corrosion-resistant concrete pipe piles, the formula includes silicate, sand, stone, cement, fly ash, anti-corrosion oil and water, and the mass percentage of each component is as follows:

[0032]

[0033]

[0034] The anti-corrosion oil is prepared by mixing tung oil and copper oleate in a ratio of 1:3.

[0035] A preparation method of a corrosion-resistant concrete pipe pile formula, the preparation method comprising the following steps:

[0036] 1) Preliminary mixing. After weighing sand, stone and cement according to a certain proportion, put them into the mixer for mixing, take a certain amount of water, and add water to the mixer while stirring;

[0037] 2) Measure a certain amount of water and put it into the container, the water temperature is controlled at about 30°C, put the silicate into the container, and stir until it is completely dissolved;

[0038] 3) Pour the liquid in step 2) into the mixer in step 1), and stop stirring after stir...

Embodiment 3

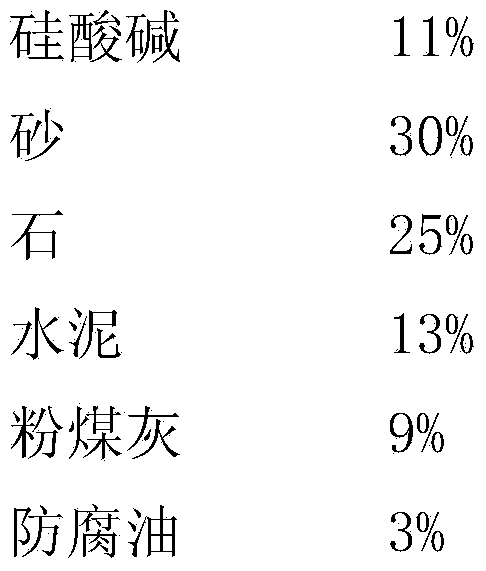

[0042] A formula for corrosion-resistant concrete pipe piles, the formula includes silicate, sand, stone, cement, fly ash, anti-corrosion oil and water, and the mass percentage of each component is as follows:

[0043]

[0044] The anti-corrosion oil is prepared by mixing tung oil and copper oleate in a ratio of 1:3.

[0045] A preparation method of a corrosion-resistant concrete pipe pile formula, the preparation method comprising the following steps:

[0046] 1) Preliminary mixing. After weighing sand, stone and cement according to a certain proportion, put them into the mixer for mixing, take a certain amount of water, and add water to the mixer while stirring;

[0047] 2) Measure a certain amount of water and put it into the container, the water temperature is controlled at about 30°C, put the silicate into the container, and stir until it is completely dissolved;

[0048] 3) Pour the liquid in step 2) into the mixer in step 1), and stop stirring after stirring for 30-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com