Method for vadaium precipitation from balck acid leaching vanadium liquid

A technology of black acid and vanadium liquid, applied in the direction of improving process efficiency, etc., can solve problems such as black acid leaching vanadium liquid precipitation method, affecting the circulation of pipelines, reducing product grade, etc., so as to avoid incomplete vanadium precipitation , Improving pipeline flow capacity and reducing vanadium loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

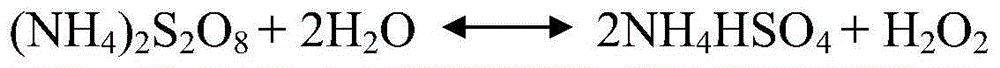

Method used

Image

Examples

Embodiment 1

[0048] Measure V 5+ , V 4+ , TFe concentrations of 31.24g / L, 1.27g / L and 0.405g / L black leachate 500mL, the solution pH = 3.82, T = 31 ℃. Add pH=3.20, the oxidizing agent solution 12ml that ammonium persulfate concentration is 600g / L to it, filter after stirring for 5min, the V in the filtrate 5+ , V 4+ , TFe concentrations were 32.44g / L, 2 o 5 Content 99.23%, V 4+ The content of TFe is <0.05%, and the content of TFe is 0.098%. The TV content of the supernatant liquid after filtration is 0.138g / L, the corresponding vanadium precipitation rate is 99.57%, and the vanadium loss in the whole process is 0.64%.

Embodiment 2

[0052] Measure V 5+ , V 4+ , TFe concentrations were 18.86g / L, 2.81g / L and 0.601g / L black leach solution 500mL, the solution pH=2.93, T=15 ℃. Add pH=3.8, the oxidant solution 21.4ml that ammonium persulfate concentration is 700g / L to it, filter after stirring for 8min, the V in the filtrate 5+ , V 4+ , TFe concentrations were 21.55g / L, 2 o 5 Content 98.78%, V 4+ The content of TFe is <0.05%, and the content of TFe is 0.154%. The TV content of the supernatant liquid after filtration is 0.096g / L, the corresponding vanadium deposition rate is 99.09%, and the vanadium lost in the whole process is 0.99%.

Embodiment 3

[0056] Measure V 5+ , V 4+ , TFe concentrations of 28.35g / L, 2.57g / L and 0.215g / L black leachate 500mL, the solution pH = 3.01, T = 27 ℃. Add pH=2.8, the oxidant solution 16.5ml that ammonium persulfate concentration is 750g / L to it, filter after stirring for 5min, the V in the filtrate 5+ , V 4+ , TFe concentrations were 30.85g / L, 2 o 5 Content 99.08%, V 4+ content <0.05%, TFe content 0.116%; the TV content of the supernatant liquid after filtration is 0.092g / L, the corresponding vanadium deposition rate is 99.70%, and the vanadium loss in the whole process is 0.52%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com