Wood-aluminum composite-type door window

A composite door and window technology, which is applied in the field of doors and windows, can solve the problems of poor combination accuracy of solid wood frame layer and aluminum frame layer, affecting the normal use of aluminum-wood doors and windows, and affecting the heat insulation effect of aluminum-wood doors and windows, so as to ensure balance and good Heat insulation effect, effect of prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

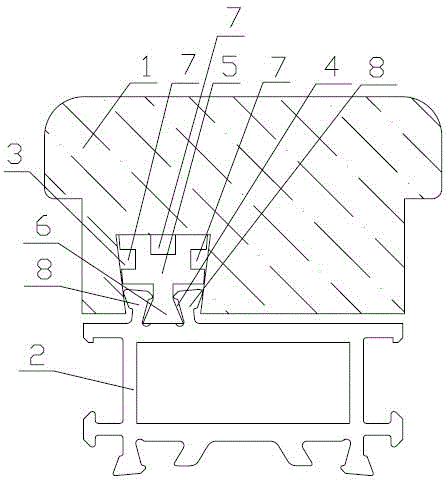

Embodiment 1

[0030] A wood-aluminum composite door and window, including a window frame and a window sash, the window frame includes a wooden frame 1 arranged on the indoor side and an aluminum frame 2 arranged on the outdoor side, and the wooden frame 1 is provided with a cross-section in the form of an inverted ladder Shaped tank body 3, the aluminum frame 2 is provided with a snap-in slot 4 symmetrically formed by two dovetail slots, a dovetail connector is provided between the slot body 3 and the snap-in slot 4, and the dovetail connector includes an embedded End 5 and clamping end 6, the upper end of embedded end 5 is composed of two symmetrically arranged "Z" shapes, the lower end is in the shape of "T", and three injection grooves 7 are formed at the upper and lower ends, and the clamping end 6 The cross-section is trapezoidal, the embedded end 5 is embedded in the tank body 3, the two clamping arms 8 of the clamping groove 4 extend into the tank body 3 and are clamped with the clamp...

Embodiment 2

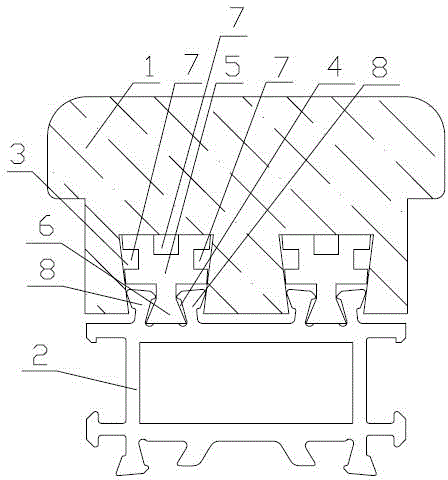

[0033]A wood-aluminum composite door and window, including a window frame and a window sash, the window frame includes a wooden frame 1 arranged on the indoor side and an aluminum frame 2 arranged on the outdoor side, and the wooden frame 1 is provided with a cross-section in the form of an inverted ladder Shaped tank body 3, the aluminum frame 2 is provided with a snap-in slot 4 symmetrically formed by two dovetail slots, a dovetail connector is provided between the slot body 3 and the snap-in slot 4, and the dovetail connector includes an embedded End 5 and clamping end 6, the upper end of embedded end 5 is composed of two symmetrically arranged "Z" shapes, the lower end is in the shape of "T", and three injection grooves 7 are formed at the upper and lower ends, and the clamping end 6 The cross-section is trapezoidal, the embedded end 5 is embedded in the tank body 3, the two clamping arms 8 of the clamping groove 4 extend into the tank body 3 and are clamped with the clampi...

Embodiment 3

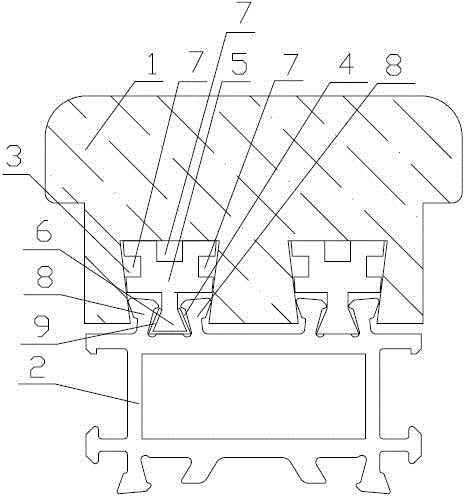

[0037] A wood-aluminum composite door and window, including a window frame and a window sash, the window frame includes a wooden frame 1 arranged on the indoor side and an aluminum frame 2 arranged on the outdoor side, and the wooden frame 1 is provided with a cross-section in the form of an inverted ladder Shaped tank body 3, the aluminum frame 2 is provided with a snap-in slot 4 symmetrically formed by two dovetail slots, a dovetail connector is provided between the slot body 3 and the snap-in slot 4, and the dovetail connector includes an embedded End 5 and clamping end 6, the upper end of embedded end 5 is composed of two symmetrically arranged "Z" shapes, the lower end is in the shape of "T", and three injection grooves 7 are formed at the upper and lower ends, and the clamping end 6 The cross-section is trapezoidal, the embedded end 5 is embedded in the tank body 3, the two clamping arms 8 of the clamping groove 4 extend into the tank body 3 and are clamped with the clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com