Integrated underground hydraulic control fully-opened type sliding sleeve abrasive blasting and packing staged fracturing device

A staged fracturing and full-opening technology, which is applied in the direction of production fluid, sealing/isolation, wellbore/well components, etc., can solve problems such as casing damage, increase construction cost, and high construction risk, and achieve fracturing The effect of increasing scale and segmented series, improving erosion resistance and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

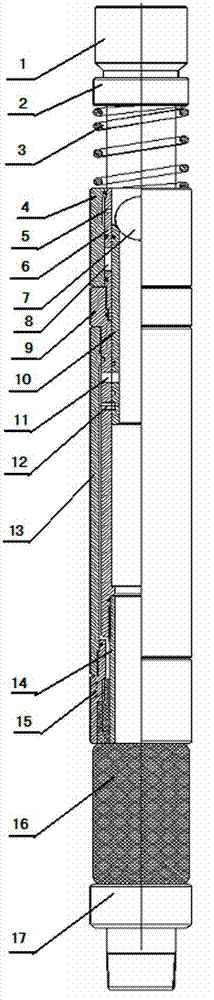

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings, without limiting the protection scope of the present invention. see figure 1 , the downhole fluid-controlled full-open sliding sleeve sandblasting and sealing integrated staged fracturing device includes a sand blaster and a packer, the sand blaster is provided with a sliding sleeve 10, an expansion packer is used, and the packer is set Rubber cartridge 16 is arranged. The sandblasting body 6 is provided with a hydraulically controlled starting hole 5 and a sandblasting port 8. The upper part of the sandblasting body 6 is covered with a spring 3 and connected to the upper joint 1. The sandblasting port sheath 4 is installed on the outside, and the sliding sleeve 10 is installed inside. The lower part is connected with the receiving cylinder 9 and connects the outer cylinder body 13 and the packer center pipe 14 through the receiving cylinder 9 to realize the connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com