A new fpc punching machine tool with automatic loading and unloading

A technology for automatic loading and unloading and punching machines, which is applied in thin material processing, object supply, metal processing, etc. It can solve the problems of low equipment safety, easy contamination of products, low processing efficiency, etc., and is conducive to efficient operation , Conducive to visual management and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

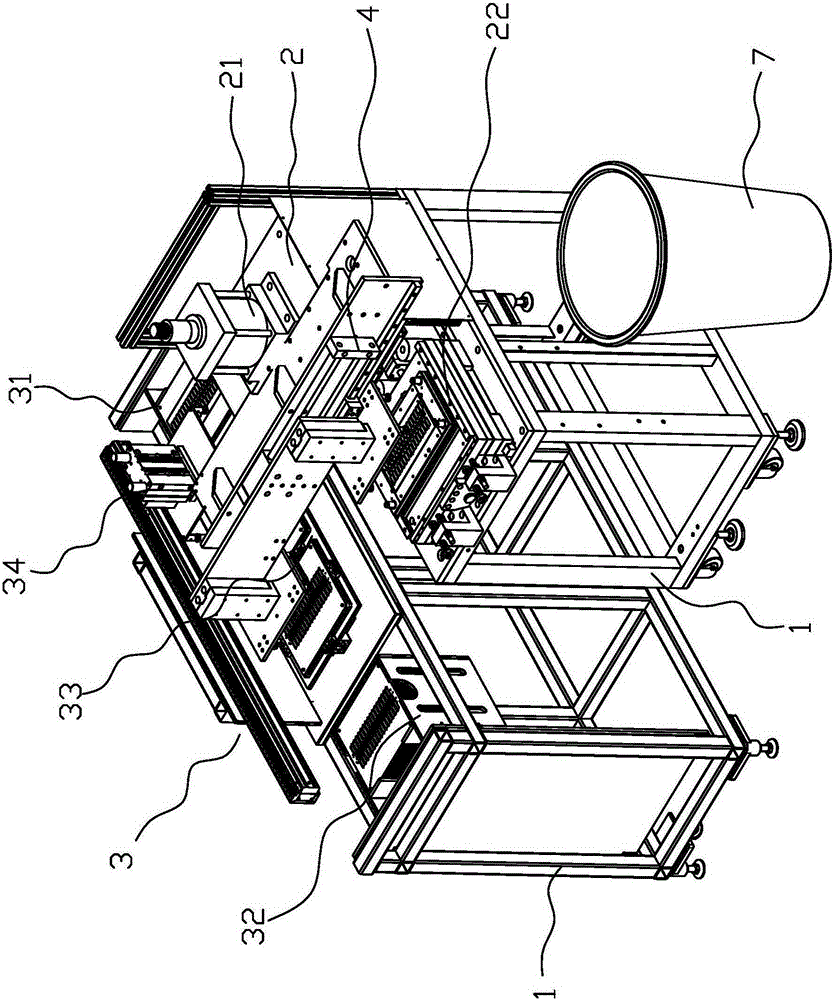

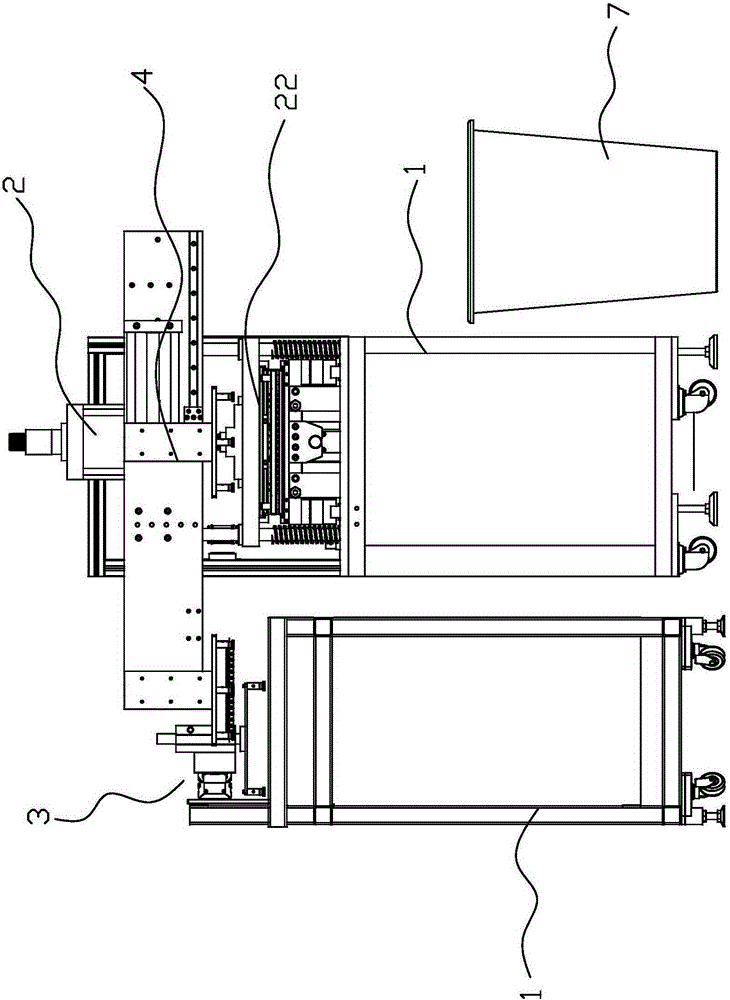

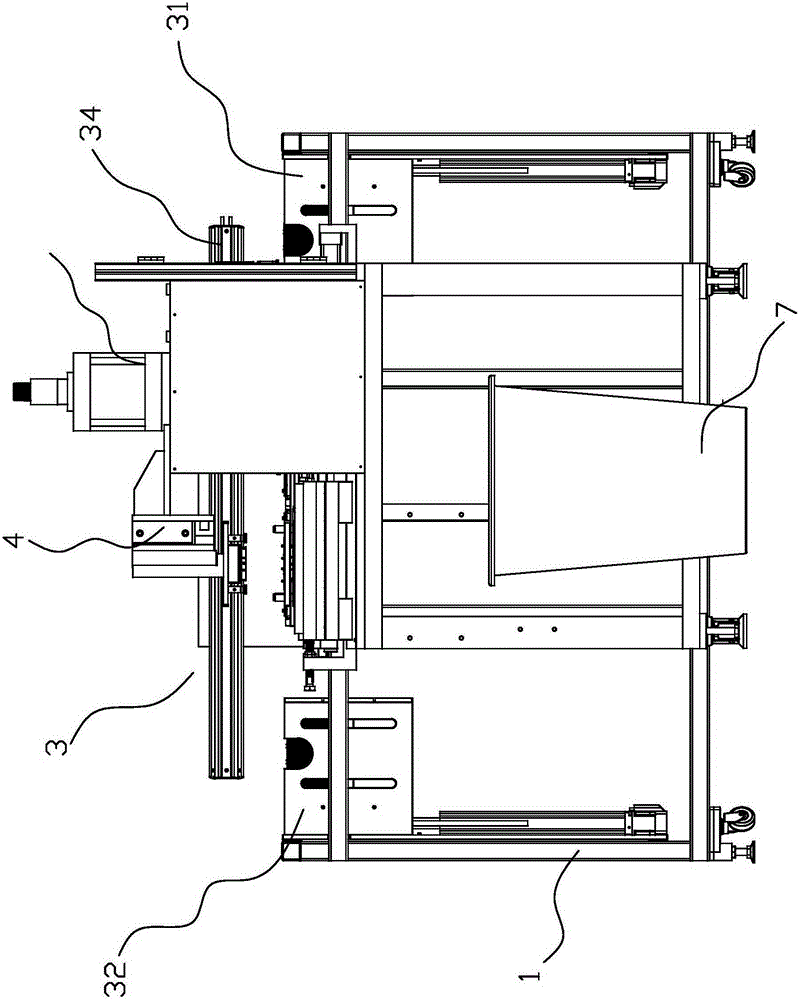

[0038] refer to Figure 1-Figure 4 , a new type of FPC punching machine tool for automatic loading and unloading, including a frame 1, a punching machine 2, a loading and unloading mechanism 3 are installed on the frame 1, and a workpiece is transported from the loading and unloading mechanism 3 to the punching machine 2. Perform punching and convey the punched products back to the conveying mechanism 4 of the loading and unloading mechanism 3 . In this embodiment, the frame 1 part where the loading and unloading mechanism 3 is installed is separated from the frame 1 part where the punching machine 2 is installed. When the present invention is actually implemented, the two parts of the frame 1 can also be fixedly connected together. This type of punching machine tool automates the working process of loading and unloading, which can greatly improve the production efficiency of the entire equipment, and at the same time has the advantages of high safety and less pollution to pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com