Patents

Literature

50results about How to "Circumstances affecting quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

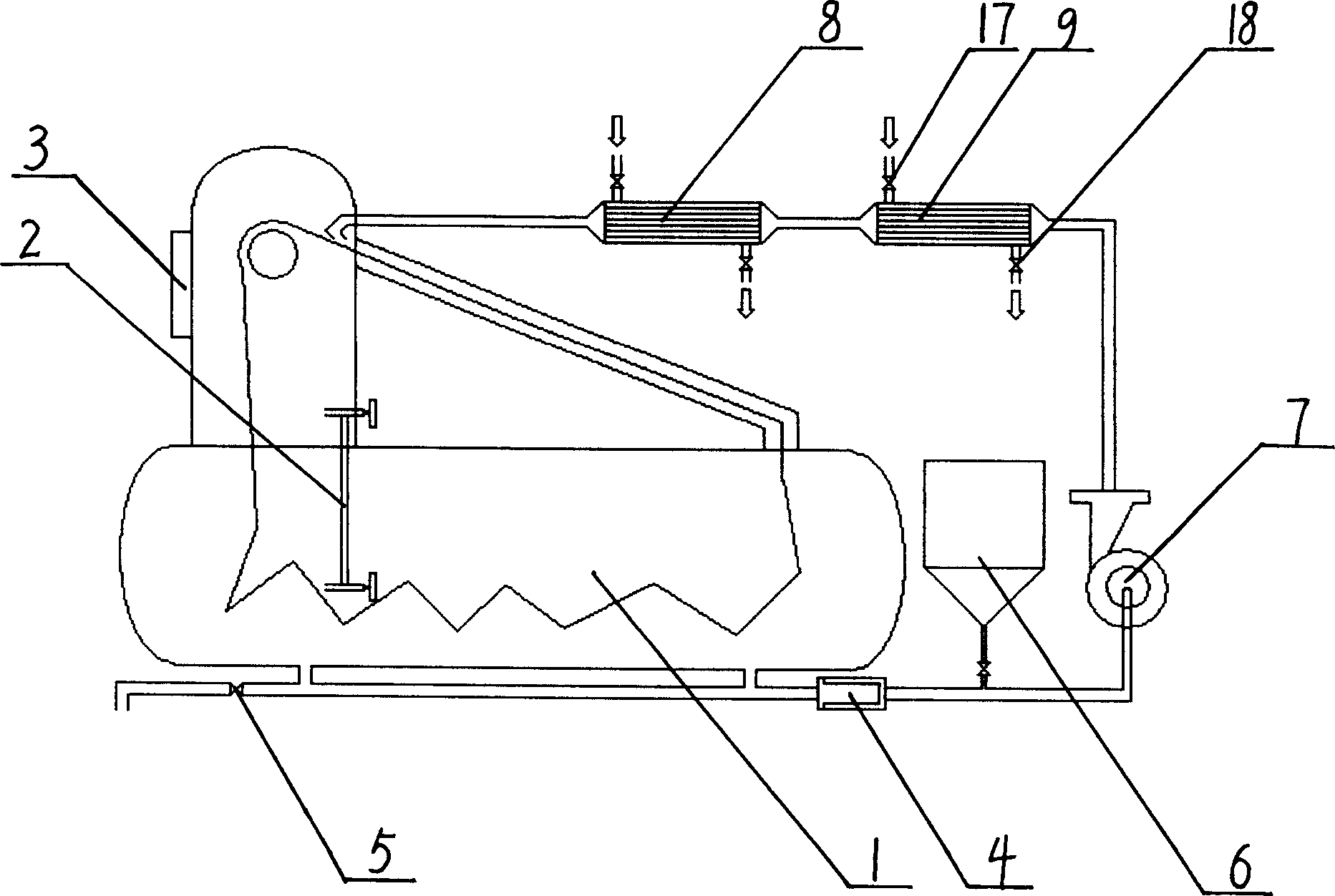

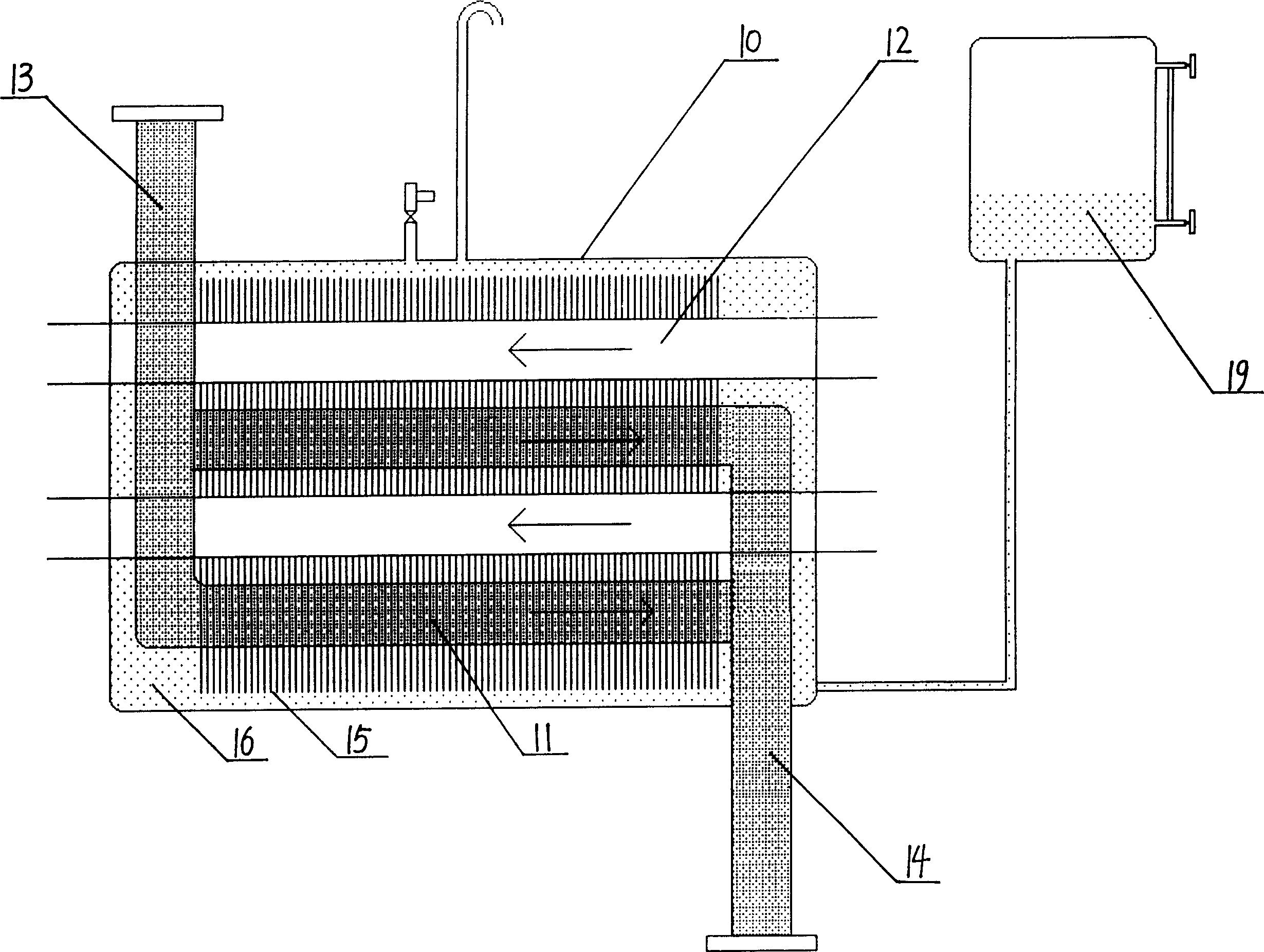

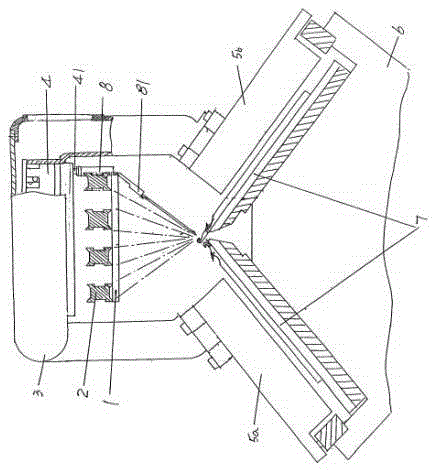

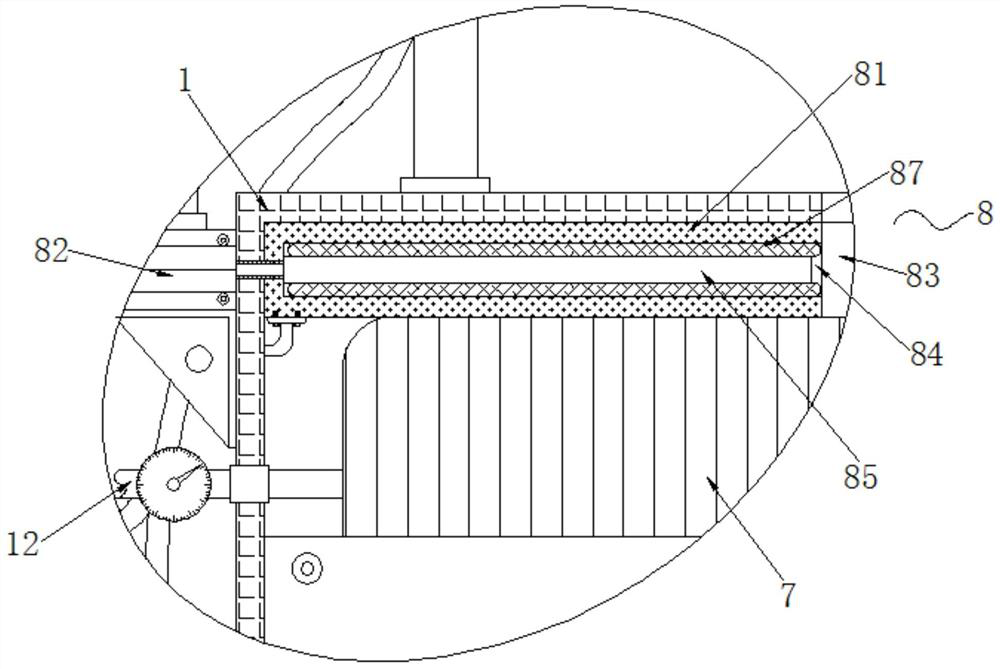

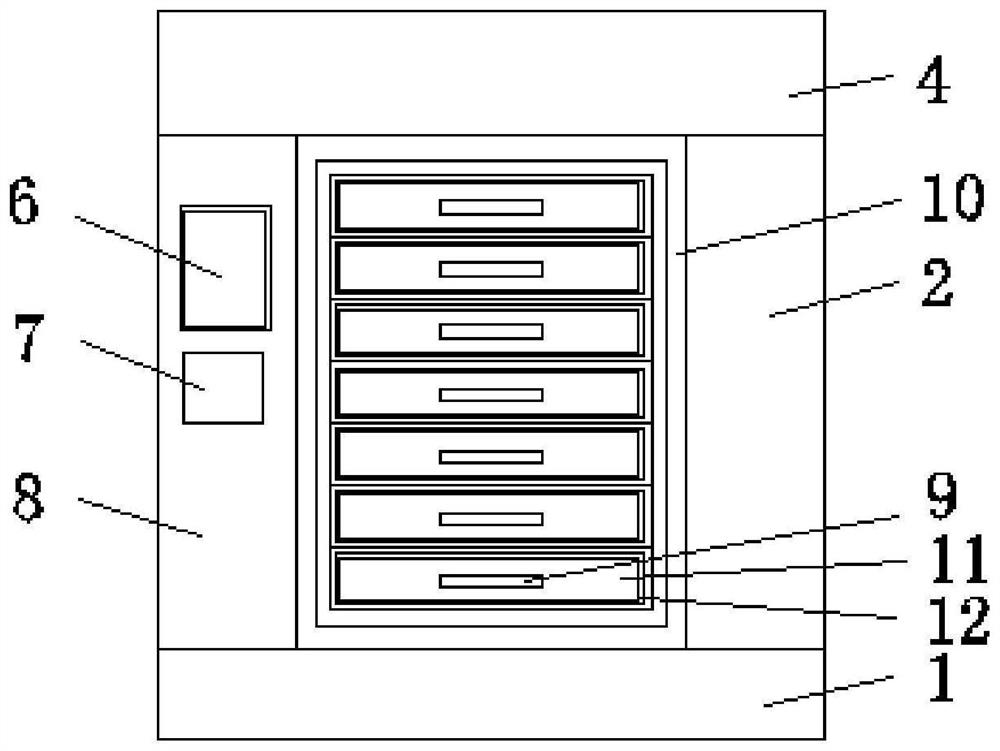

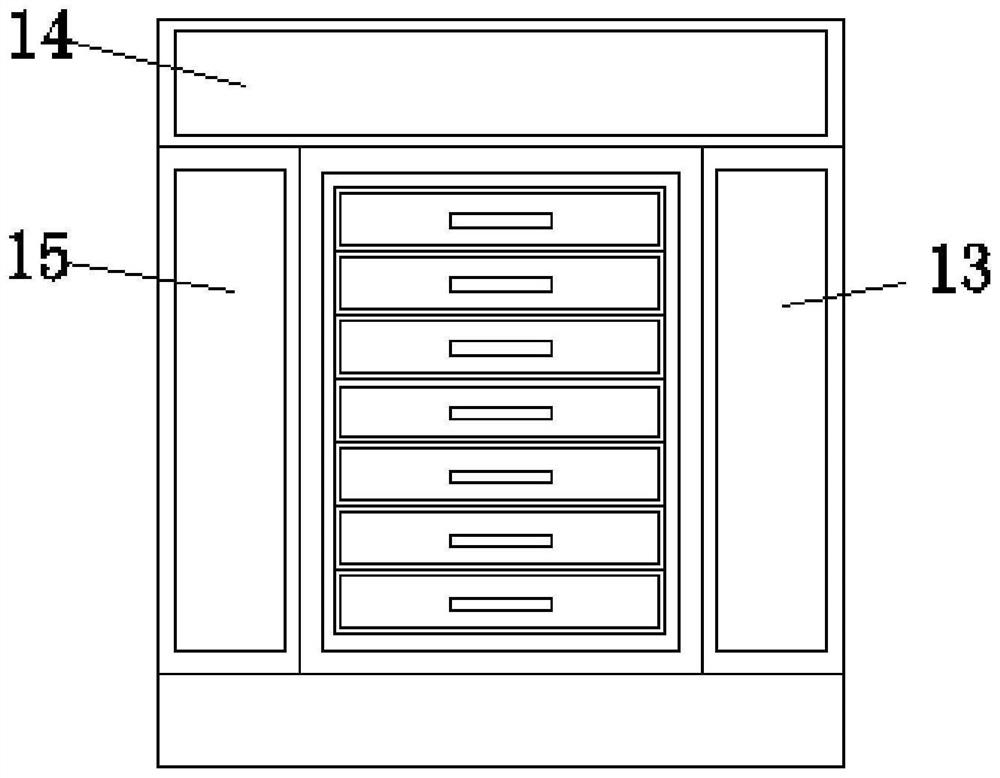

Oil heating type dyeing machine

InactiveCN1635207AReached temperatureCircumstances affecting qualityTextile treatment machine arrangementsPulp and paper industryWater level

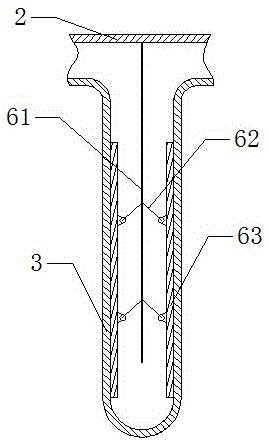

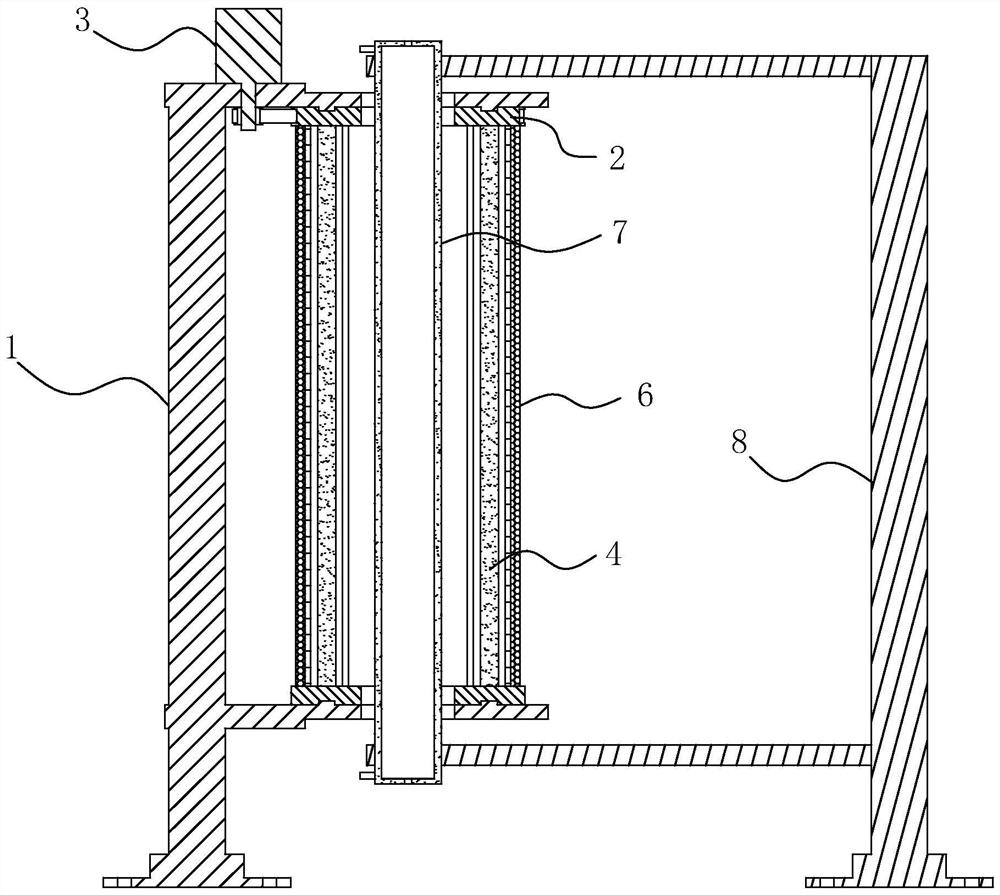

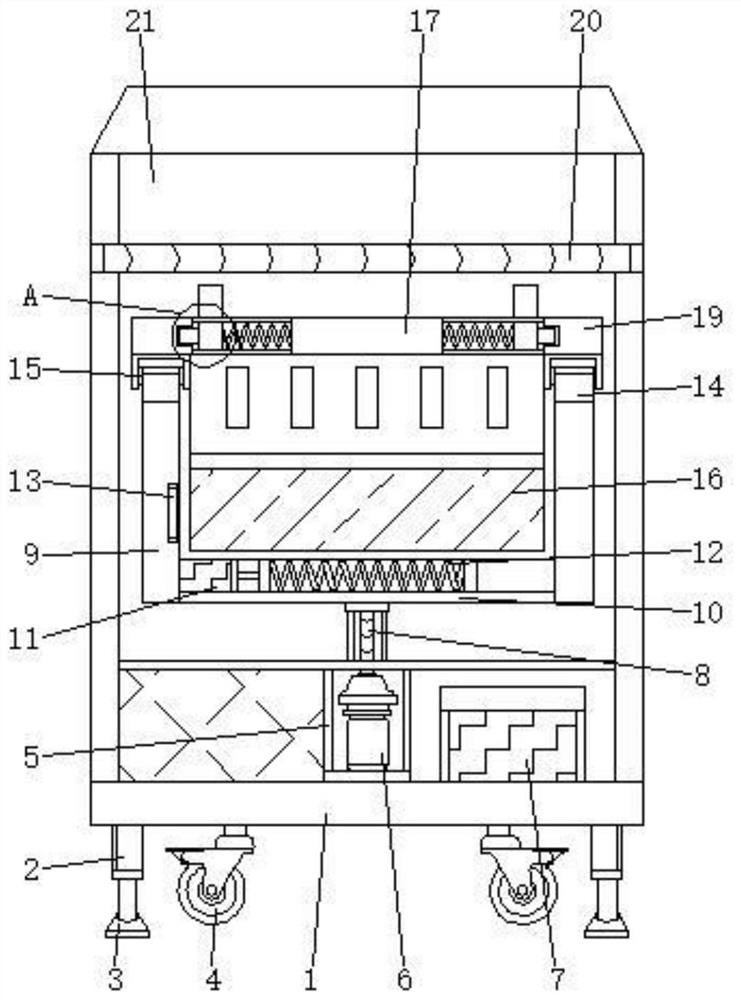

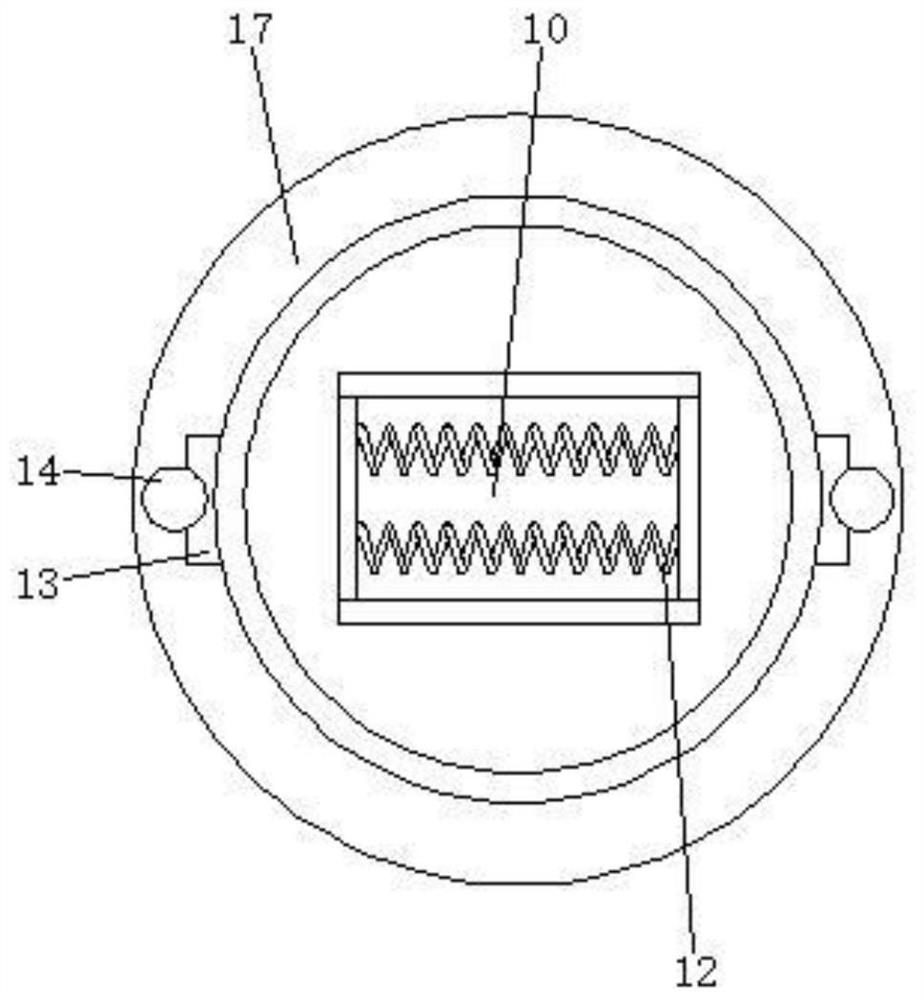

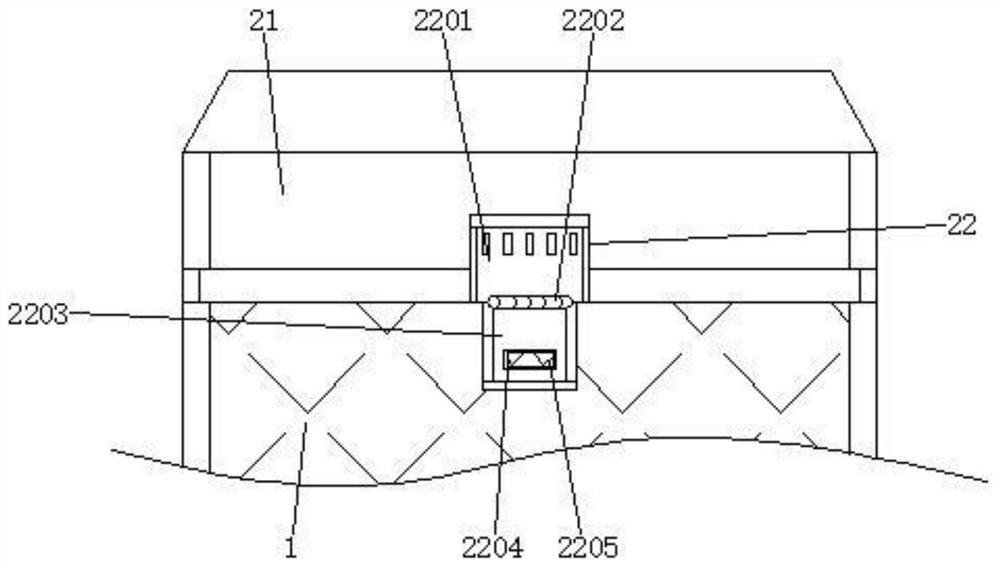

The invention relates to a dyeing machine, especially to an oil heating type dyeing machine, comprising a cloth dyeing cylinder, in which a water level pipe is arranged, and on one side of the top of which, a cloth enter-exit port is arranged. The cloth dyeing cylinder is connected to filter apparatus, dye liquor value through channels; the other end of the filter apparatus is connected to a charging bucket, dye liquor circulating water pump through channels; the series water cooling exchanger and oil heating exchanger is connected between cloth dyeing cylinder and dye liquor circulating water pump through channels. The invention can obtain the needed dye liquor temperature by cooling and heating the dye liquor by the water cooling exchanger and oil heating exchanger.

Owner:劳关明

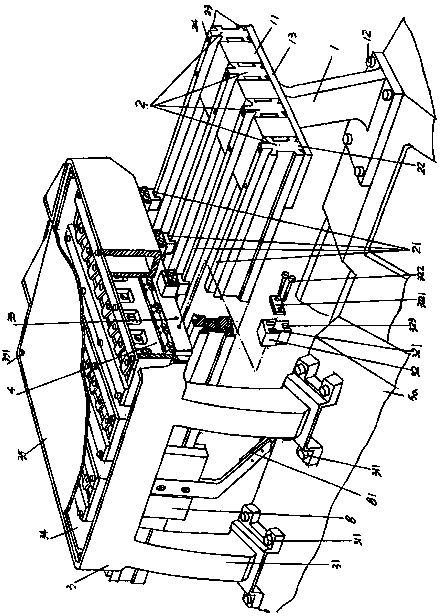

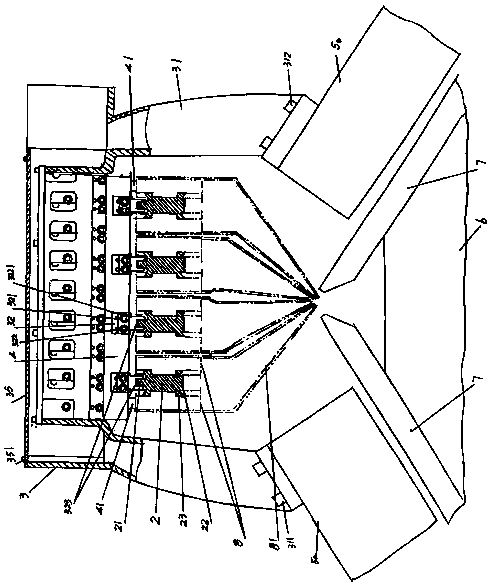

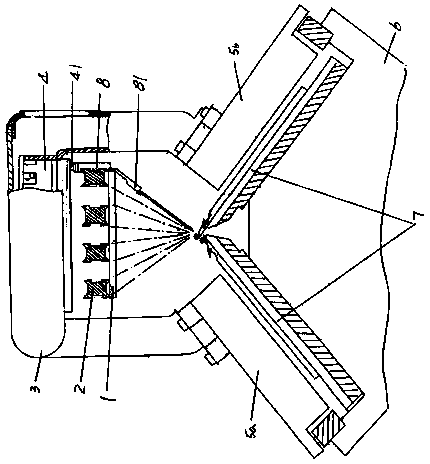

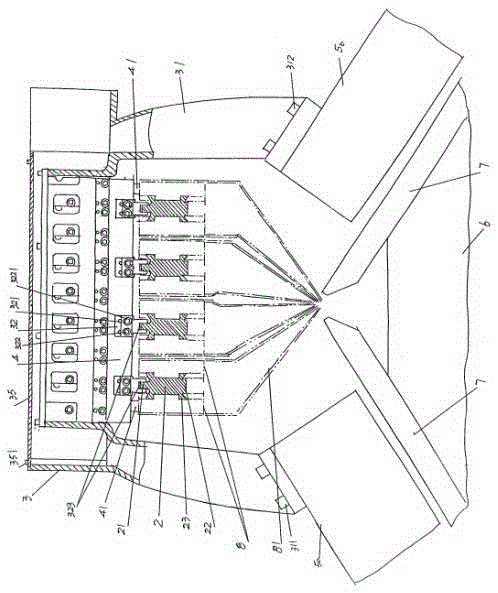

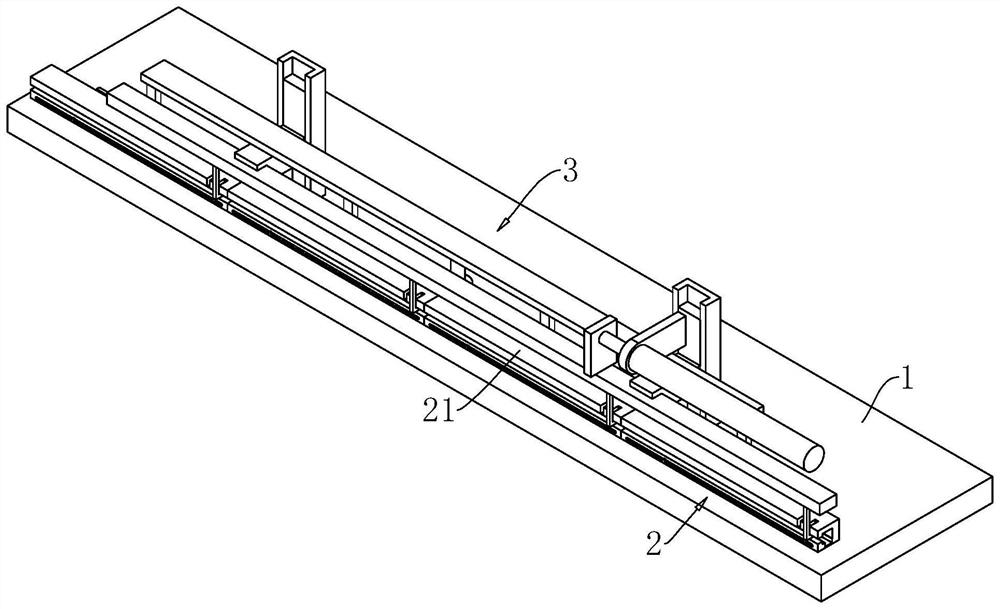

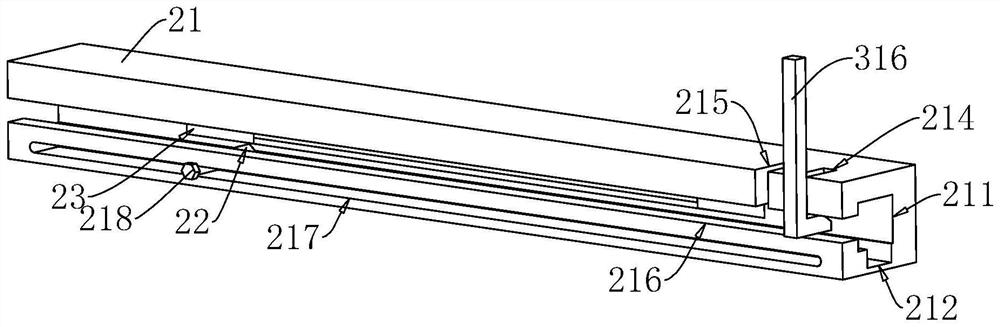

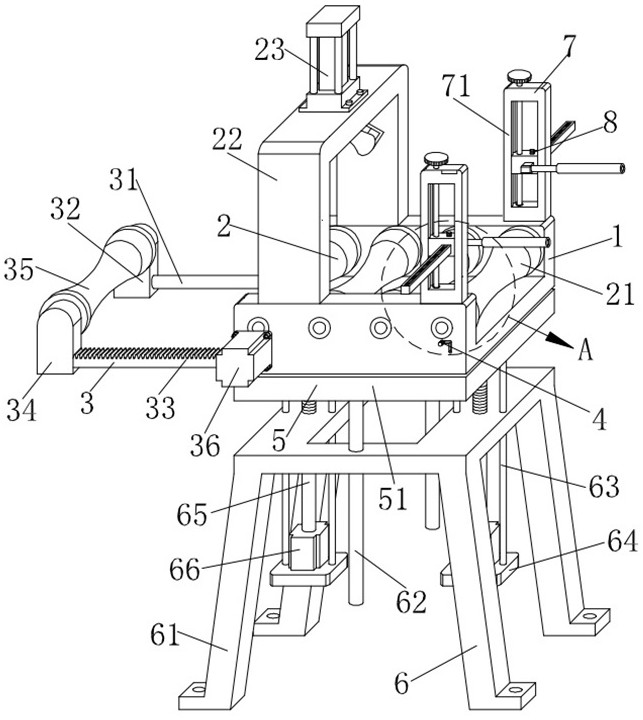

Fitting structure of top lever device and shuttle changing device of computerized flat knitting machine

The invention provides a fitting structure of a top lever device and a shuttle changing device of a computerized flat knitting machine, and belongs to the technical field of computerized flat knitting machines. The top lever device comprises a pair of shutter guide rail brackets and a group of shuttle guide rails; the shuttle changing device comprises a nose connecting base and a group of shuttle changing control electromagnetic valves; the fitting structure of the top lever device and the shuttle changing device is characterized in that shuttle guide rail attached guide bars are arranged on the surfaces of the upward sides of the group of shuttle guide rails in the length direction respectively, shuttle guide rail limiting sliders are fixed on the front and rear sides of the nose connecting base respectively, and the shuttle guide rail limiting sliders are in sliding fit with the shuttle guide rail attached guide bars. In the process when the shuttle changing control electromagnetic valves moving along with the nose connecting base drive shuttles to move back and forth along the shuttle guide rails, the shuttle guide rails do not, for example, vibrate and shake, so as to ensure that the shuttles driven by the shuttle changing control electromagnetic valves move steadily on the shuttle guide rails and yarns can be accurately fed into a knitting mechanism by the shuttles; therefore, the situation that the quality of the fabrics are finally affected by missed stitch due to inaccurate yarn feeding can be avoided.

Owner:JIANGSU JINLONG TECHNOLOGY CO LTD

Melting process of casting aluminum bar for aluminum profile

The invention provides a melting process of a casting aluminum bar for aluminum profile. Aluminum raw materials are put into a smelting furnace, nitrogen is injected into the smelting furnace, and airin the smelting furnace is discharged; the aluminum raw materials are melted into molten aluminum liquid by using the smelting furnace, and the molten aluminum liquid is evenly vibrated and stirred by using ultrasonic waves; impurities on the surface of the molten aluminum liquid and impurities on the bottom layer of the molten aluminum liquid are separately discharged, and air in an aluminum barcasting device is discharged by using the heated nitrogen and the aluminum bar casting device is preheated; the molten aluminum liquid is extruded from bottom to top into an aluminum bar die tube ofthe aluminum bar casting device; redundant molten aluminum liquid is collected; an aluminum bar is formed by cooling the aluminum bar die tube and the molten aluminum liquid inside the aluminum bar die tube; an anti-oxidation coating is formed by spraying anti-oxidation coating on the surface of the aluminum bar; and the aluminum bar is taken out. According to the melting process of the casting aluminum bar for the aluminum profile, impurities are obviously decreased, the oxidation degree is reduced, and the quality of the aluminum bar and aluminum profile products is enhanced.

Owner:奋安铝业股份有限公司

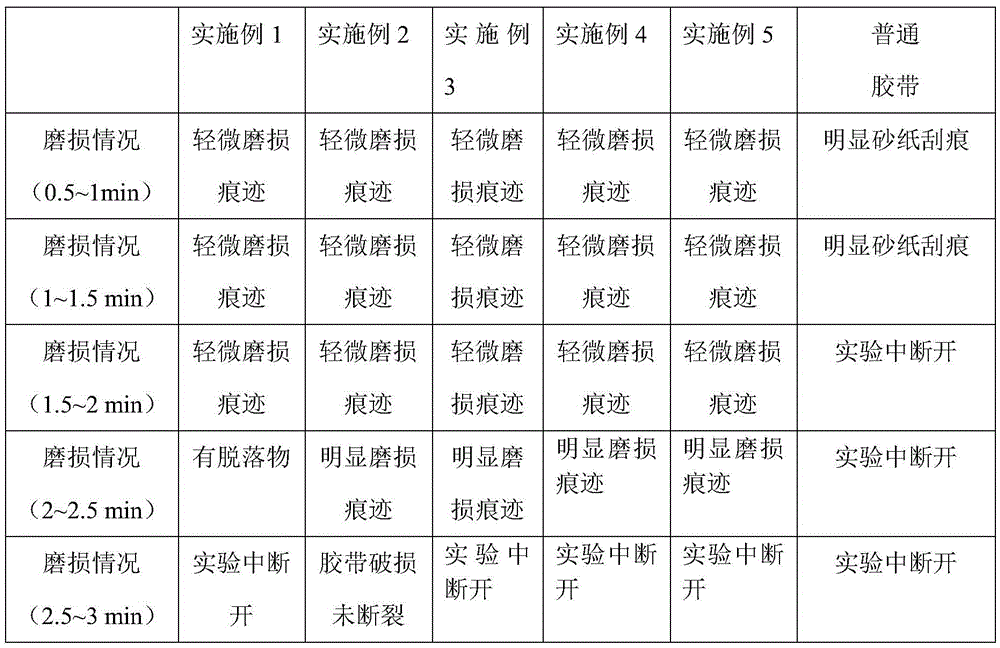

Preparation method of wear-resistant adhesive tape

The invention discloses a preparation method of a wear-resistant adhesive tape. The preparation method comprises the following steps: mixing butadiene styrene rubber, natural rubber, a fortifier, an accelerant, an ultraviolet screening agent, a plasticizer, an anti-aging agent, polyester staple fibers and silicate minerals to obtain a mixture; plasticizing the mixture by virtue of a double-roller open mill, calendaring by virtue of a five-roller calender to form a film base material, coating the film base material obtained in step 3 with the adhesive, and drying; and adhering a release film onto the other surface of the film base material, and stripping and slicing to form the adhesive tape. The adhesive tape has the characteristics of high abrasion resistance, excellent performance and low cost.

Owner:NINGBO JIXIANG PLASTIC PROD CO LTD

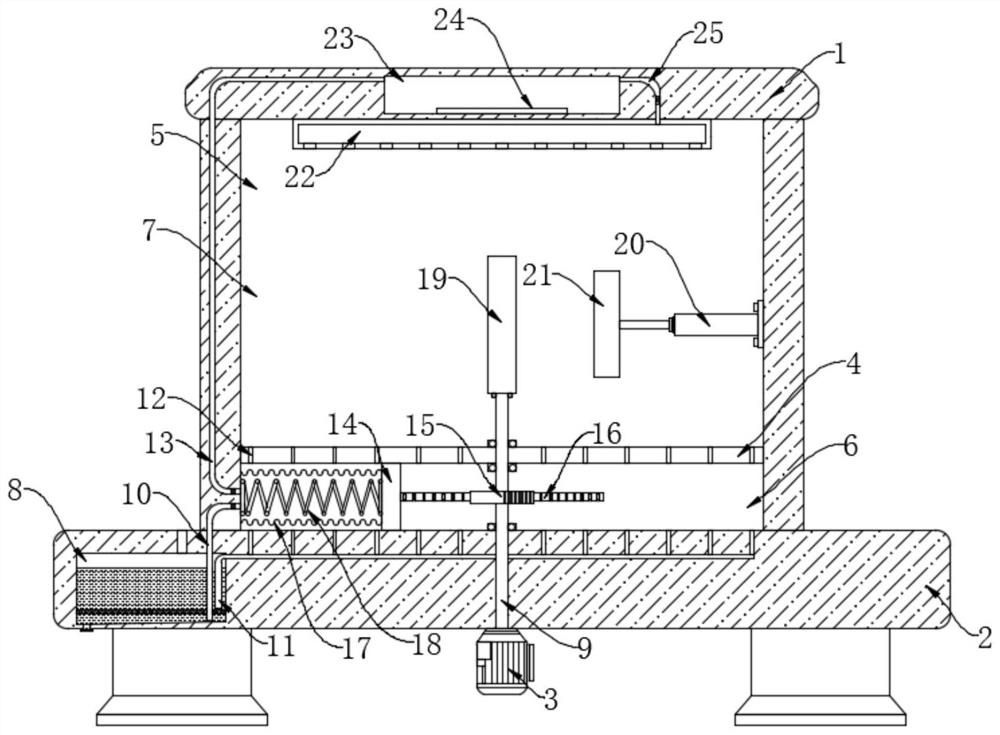

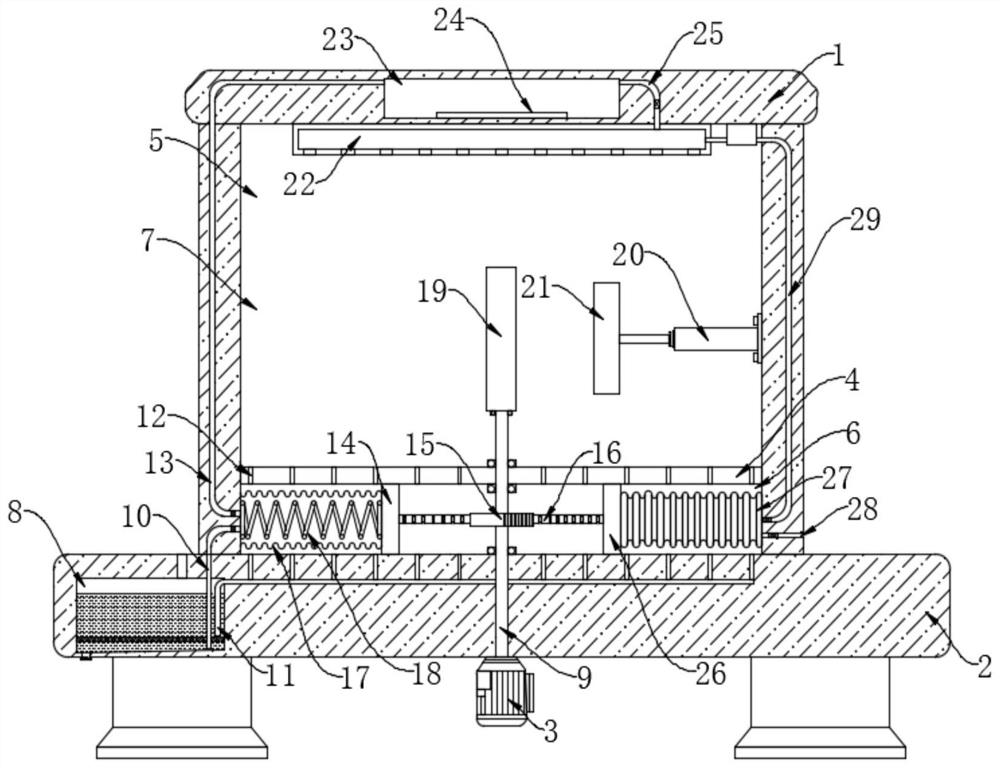

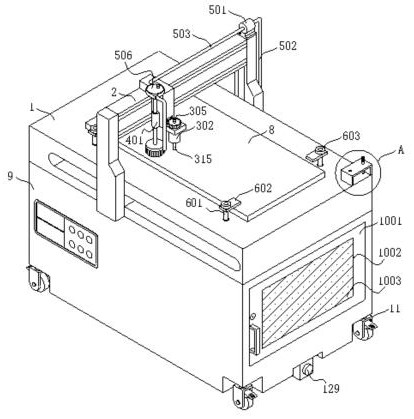

Dust falling and noise reduction type leather shoe sole polishing device

InactiveCN112545115ABig spaceReduce pressureGrinding carriagesShoemaking devicesPolishingCooling effect

The invention discloses a dust falling and noise reduction type leather shoe sole polishing device which comprises a cabinet body, a base is fixedly connected to the lower end of the cabinet body, anatomization cavity and a square cavity are sequentially formed in the cabinet body from top to bottom, a transverse plate is horizontally arranged in the square cavity, and the square cavity is divided into a polishing chamber and a reciprocating cavity through the transverse plate. The polishing chamber is located above the reciprocating cavity, and a liquid storage cavity is formed in the base.In the grinding process of the device, atomized water is used for adsorbing dust in the grinding machine, then the dust is brought into the liquid storage cavity through the accumulation of the water,so that people clean the dust conveniently, meanwhile, the atomized water falls on a grinding cylinder and a shoe sole, the cooling effect can be achieved, the service life of the grinding cylinder is prolonged, and the atomized water can reduce noise generated in the grinding process to a certain extent.

Owner:郑州市林慕商贸有限公司

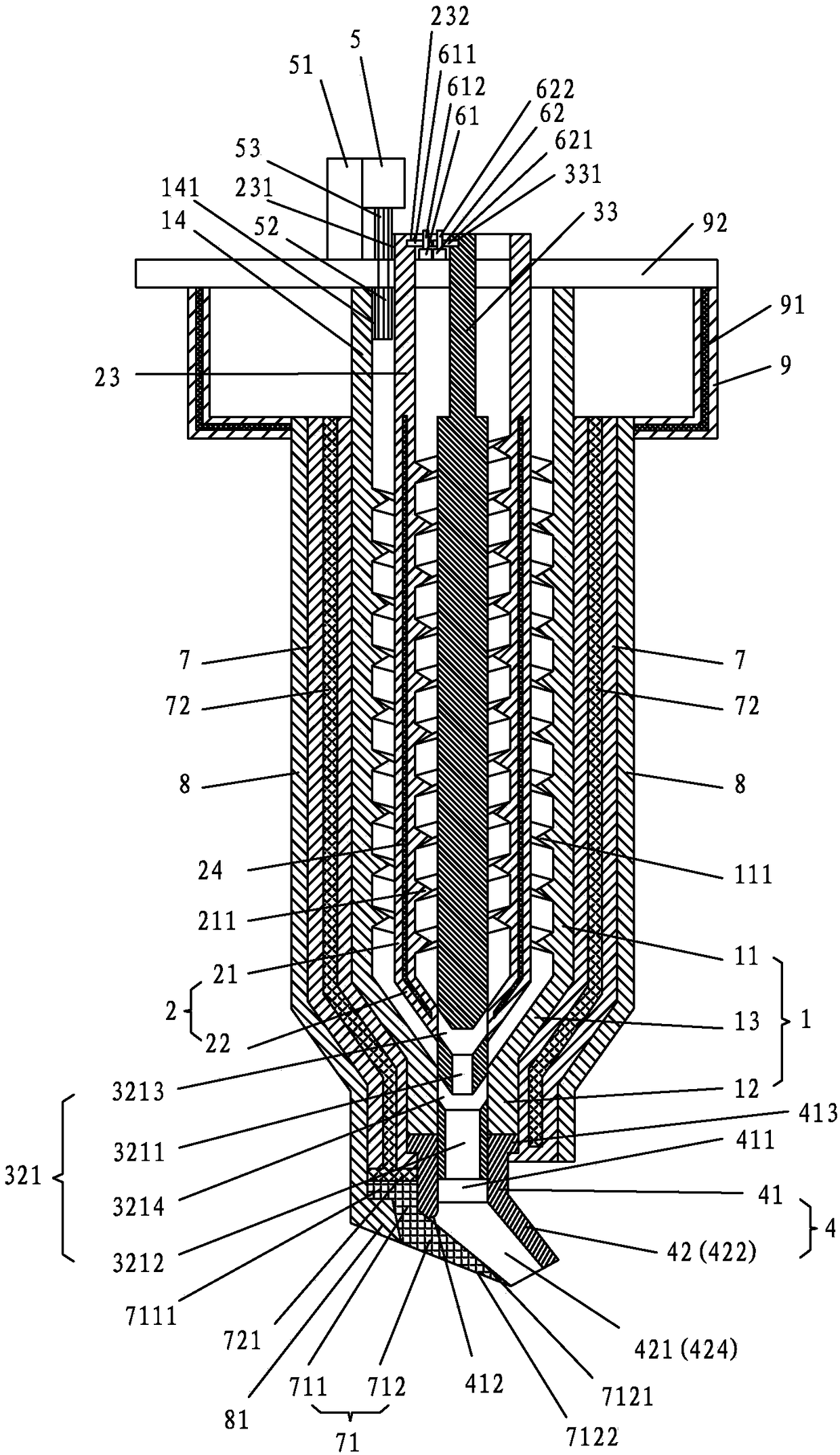

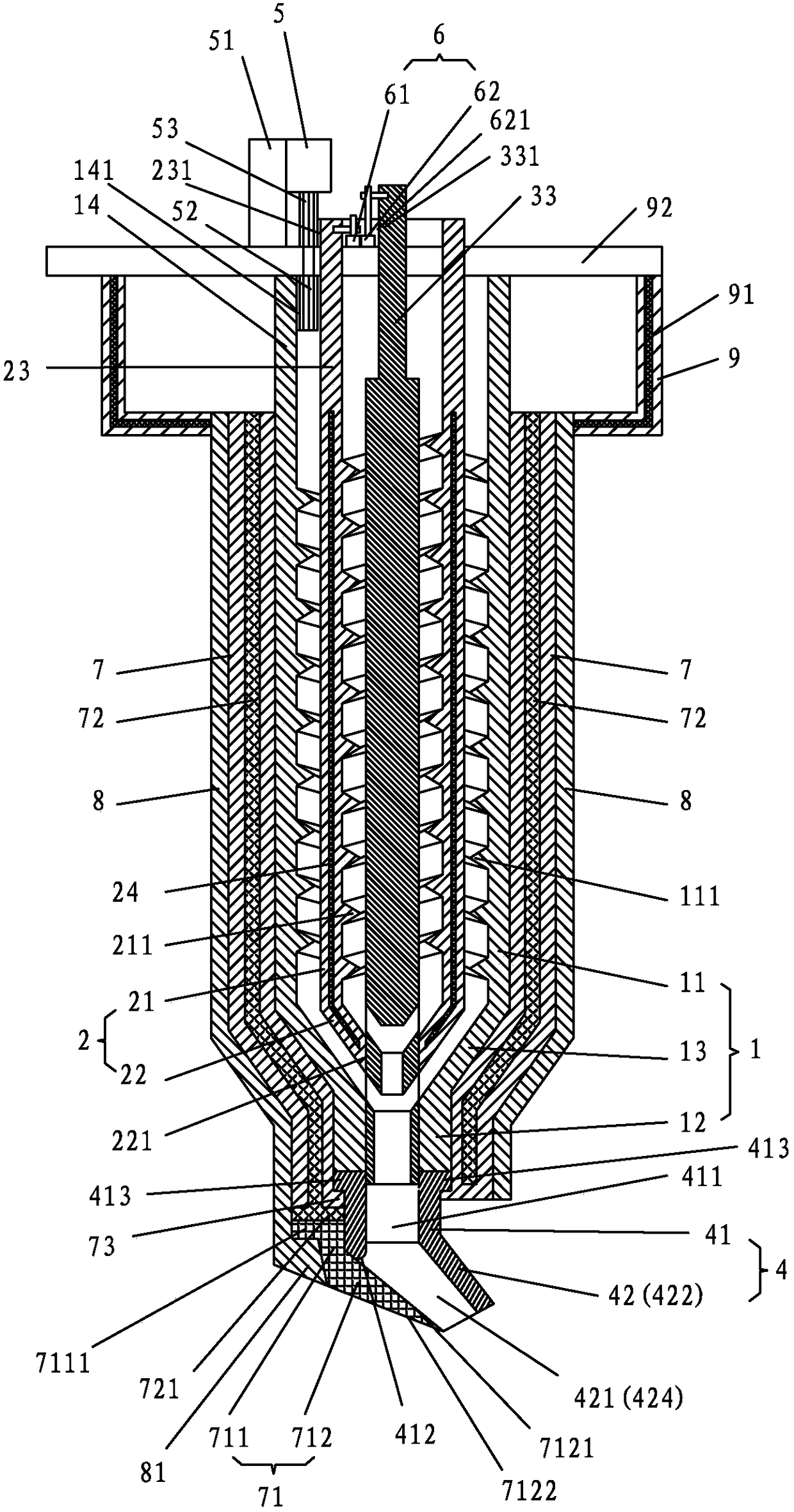

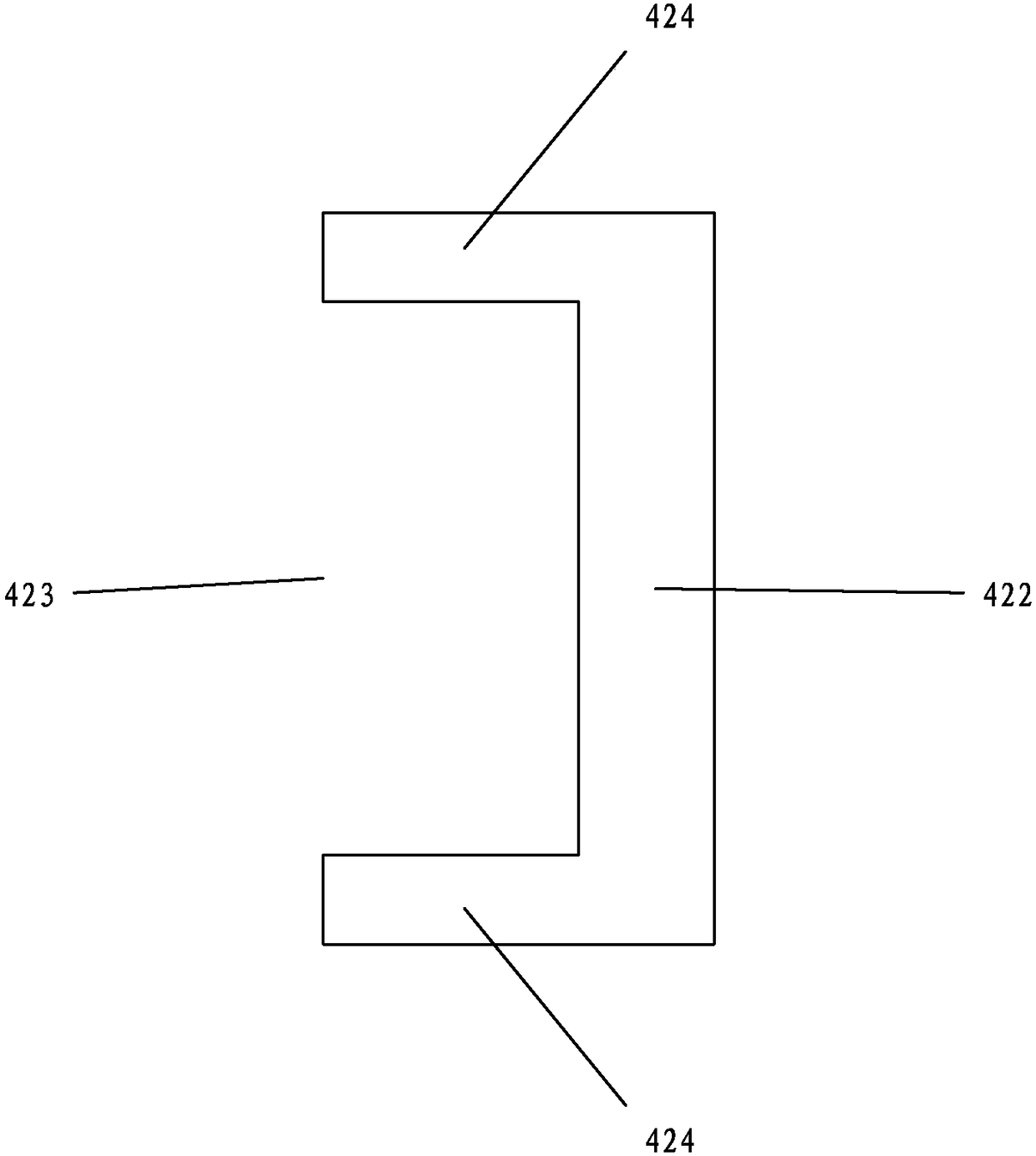

Finished-product integrally jointed type three-dimensional printing head

ActiveCN108312527AIncrease temperatureImprove liquidityManufacturing heating elementsManufacturing material handlingWhole bodyJoints types

The invention provides a finished-product integrally jointed type three-dimensional printing head. The finished-product integrally jointed type three-dimensional printing head breaks through a construction form of a traditional three-dimensional printing head; a heating layer is used for carrying out further heating on raw materials in an outer conveying pipe, so that the temperature and flowability of the raw materials in the outer conveying pipe are higher than the temperature and flowability of raw materials in an inner conveying pipe; in a printing process, a lower inclined plane of a flexible heating block is in contact with a printing layer which is slightly cooled and condensed on a lower layer, so that the upper surface of the printing layer on the lower layer can be melted; meanwhile, the raw materials flowing out from an upper feeding hole and the raw materials flowing out from a lower feeding hole are gathered in a material discharging hole; the raw materials flowing out from the lower feeding hole are uniformly distributed at the periphery of the raw materials flowing out from the upper feeding hole to cover the periphery; then the raw materials flow out from a third channel and are in contact with the printing layer on the lower layer, so that the raw materials flowing out from the upper feeding hole and the printing layer on the lower layer are naturally fused toform a whole body, and an obvious jointing surface is not formed between a printing layer on an upper layer and the printing layer on the lower layer; the jointing between the adjacent printing layersis firmer.

Owner:QUANZHOU BILINED TECH CO LTD

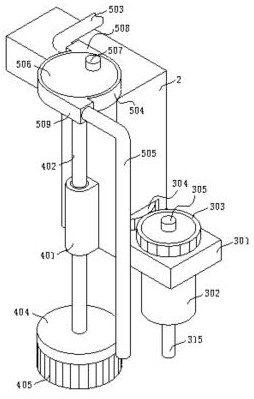

Carving device capable of timely polishing after carving and used for jujube wood artware processing

PendingCN113561691ASolve the problem of easily injured staffReduce the impact on physical healthEdge grinding machinesModel makingPolishingWorkbench

The application relates to a carving device capable of timely polishing after carving and used for jujube wood artware processing. The carving device comprises a workbench, a three-axis driving module is arranged at the top of the workbench, a carving mechanism, a sweeping mechanism and a dust collection mechanism are arranged on the three-axis driving module, the sweeping mechanism and the dust collection mechanism are located on one side of the carving mechanism, a base plate and four fixing mechanisms located on the two sides of the base plate correspondingly are fixedly installed at the top of the workbench. Two clamping blocks can clamp a carving knife through a short-distance air cylinder in an arranged carving mechanism, after jujube wood is carved through the carving knife, the carving mechanism is moved to the position above a knife storage mechanism through the three-axis driving module, the carving knife is inserted into a knife hole, the short-distance air cylinder drives a connecting plate to ascend so that the clamping blocks can be separated from the carving knife, a rotating shaft is moved to the position above a polishing knife through the three-axis driving module, the top end of the polishing knife is inserted into the rotating shaft and clamped by the two clamping blocks, and the carved jujube wood can be polished in time through the polishing knife.

Owner:榆林信天游文化股份有限公司

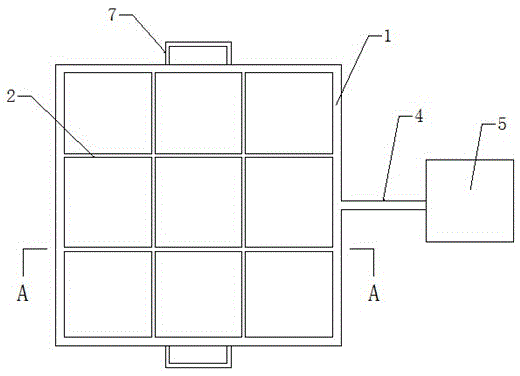

Air hole pre-setting device for cast sand mold

The invention discloses an air hole pre-setting device for a cast sand mold. The air hole pre-forming device comprises a frame body, an air pipe connected with the frame body and an air pump communicated with the air pipe. The frame body comprises a framework and an air bag. A plurality of supporting rods arranged in a crossed manner are arranged in the framework. The supporting rods are fixed to the framework. The air bag is fixed to the lower ends of the framework and the supporting rods. The air bag is communicated with the air pipe. A plurality of air bag pillars are formed at the lower end of the air bag in a downward protruding manner. Pressing pillars and two supporting plates with arc cross sections are arranged in the air bag pillars. The top ends of the pressing pillars are fixed to the supporting rods. The pressing pillars are located between the corresponding two supporting boards. The outer walls of the supporting plates are fixed to the inner walls of the air bag pillars. Two ejector rods are longitudinally arranged on the inner wall of each supporting plate. The other ends of the ejector rods are connected with the pressing pillars. According to the scheme, the depth, the size and the number of air holes can be preset, multiple air holes can be machined at a time, machining efficiency is improved, compactness and breathability of molding sand cannot be changed, the cast quality cannot be influenced, exhaust effects are good, and operation is simple.

Owner:CHONGQING QIANGXIN MACHINERY MFG CO LTD

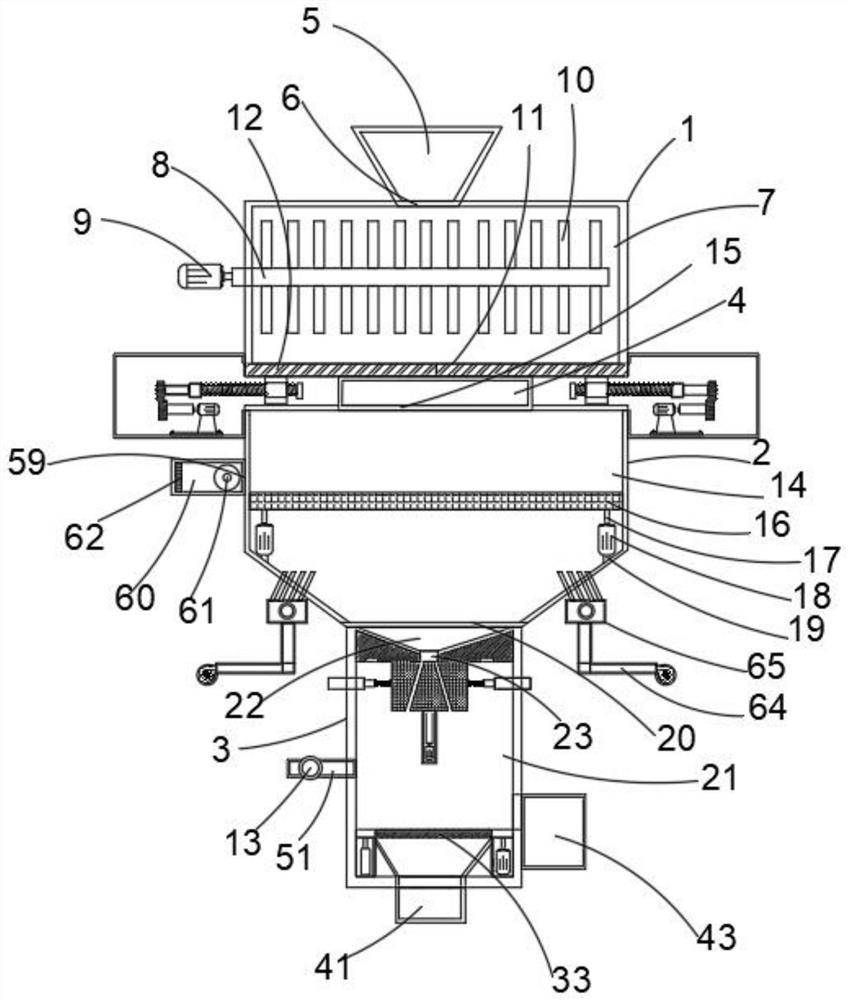

Rice milling device for rice processing and working method thereof

InactiveCN112871251AStir wellPrevent overflowGrain huskingGrain polishingAgricultural scienceAgricultural engineering

The invention discloses a rice milling device for rice processing. The rice milling device comprises a feeding mechanism, a screening mechanism and a rice milling mechanism, wherein the feeding mechanism is connected with the screening mechanism through a first feeding channel; the rice milling mechanism is arranged below the screening mechanism; the feeding mechanism comprises a feeding groove; the lower portion of the feeding groove is fixedly connected with the feeding groove through a first feeding port; a stirring shaft is transversely fixed to the interior of the feeding groove; the left end of the stirring shaft penetrates through the left side wall of the feeding groove and then is fixedly connected with a rotating motor; and a plurality of stirring blades are fixed to the stirring shaft. When the discharge flow needs to be reduced, a driving motor drives a driving wheel to rotate in the opposite direction, so that a fixed block moves towards the inner side, and a gap between two discharging plates is reduced; and the feeding speed and flow are controlled by controlling the gap between the two discharging plates, so that quantitative feeding is achieved, the overflow of brown rice is prevented, the blockage of the brown rice is avoided, and the rice milling processing quality of the brown rice is effectively guaranteed.

Owner:寿县昱奕米业股份有限公司

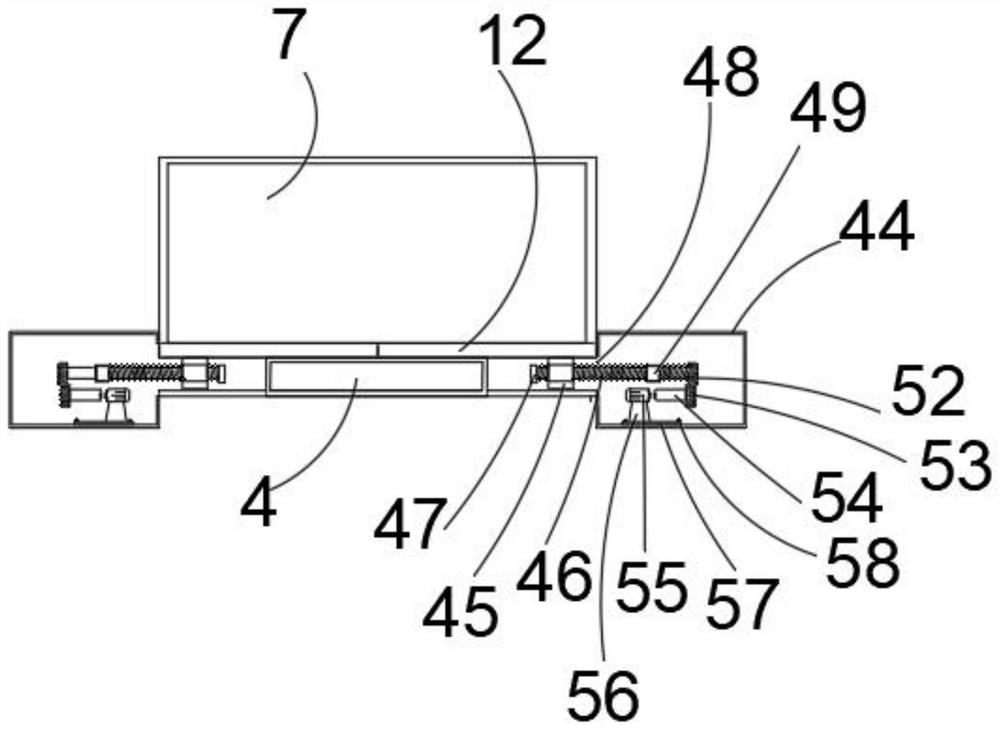

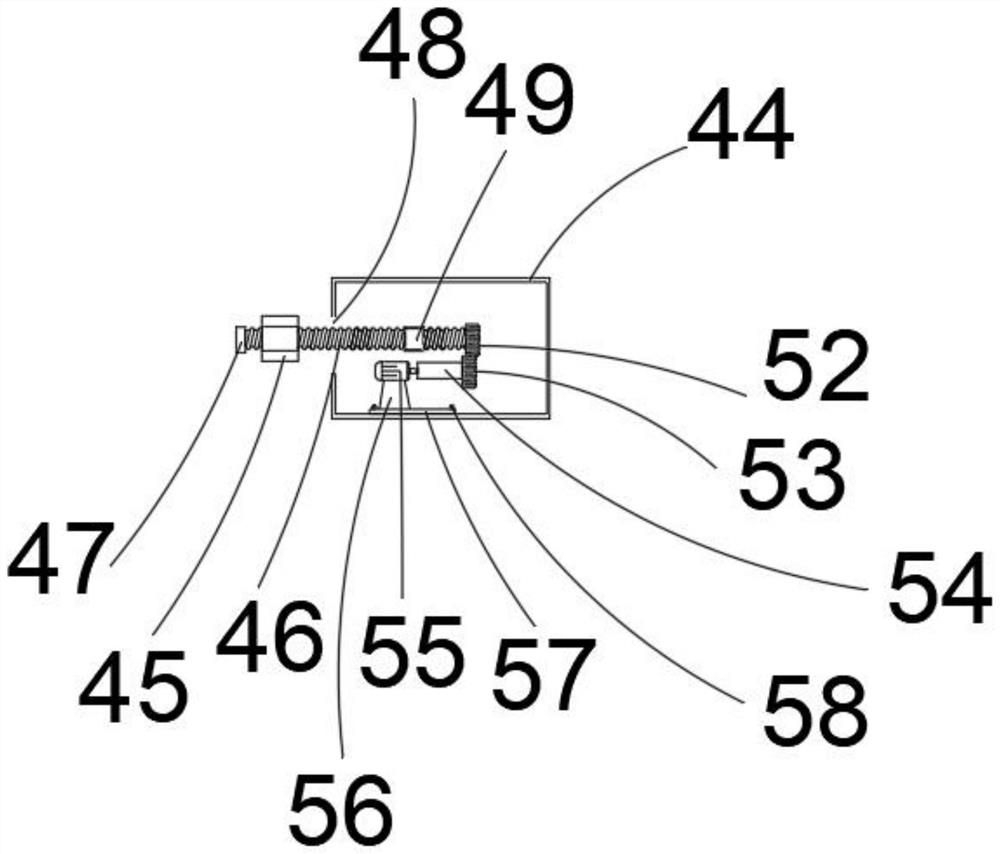

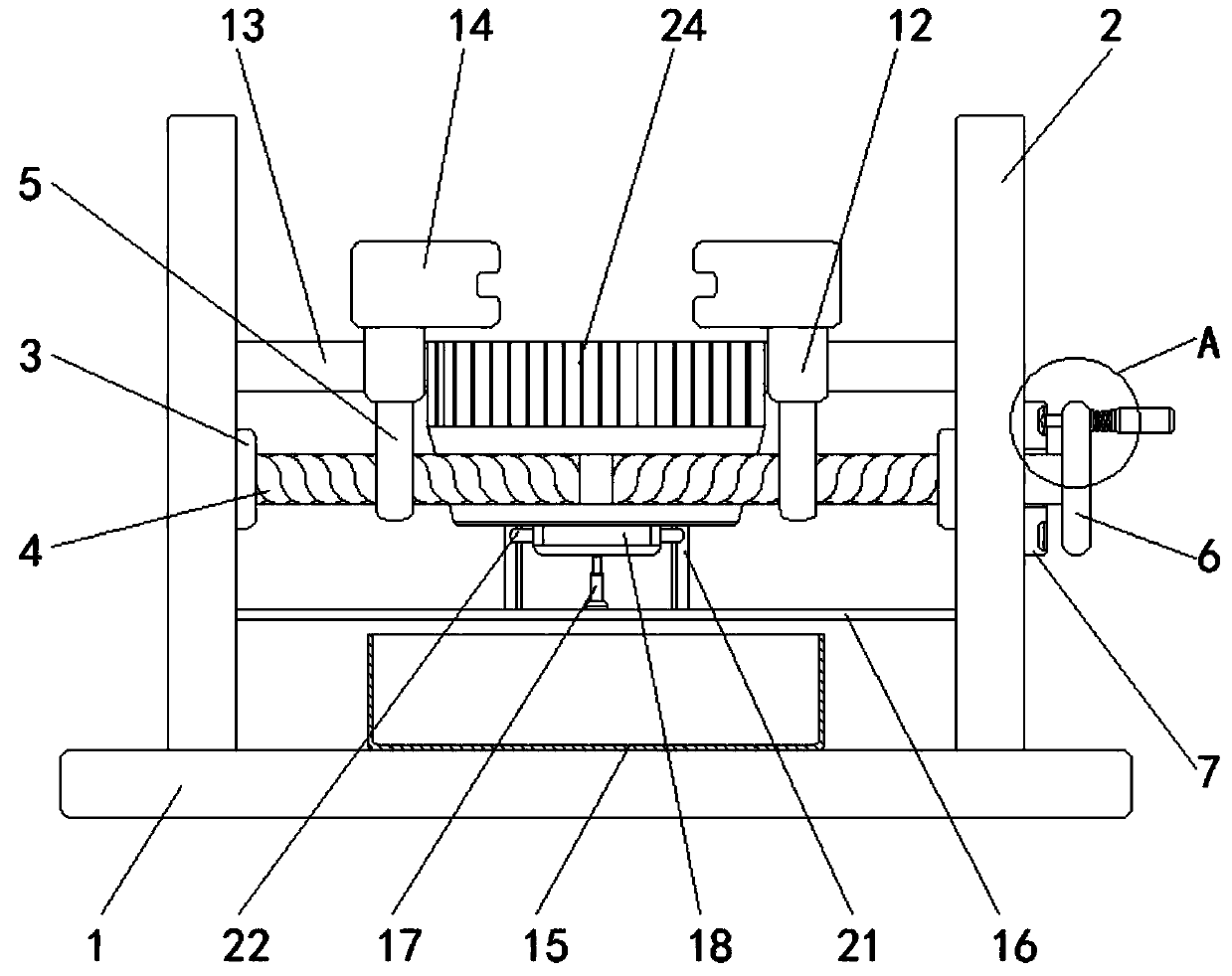

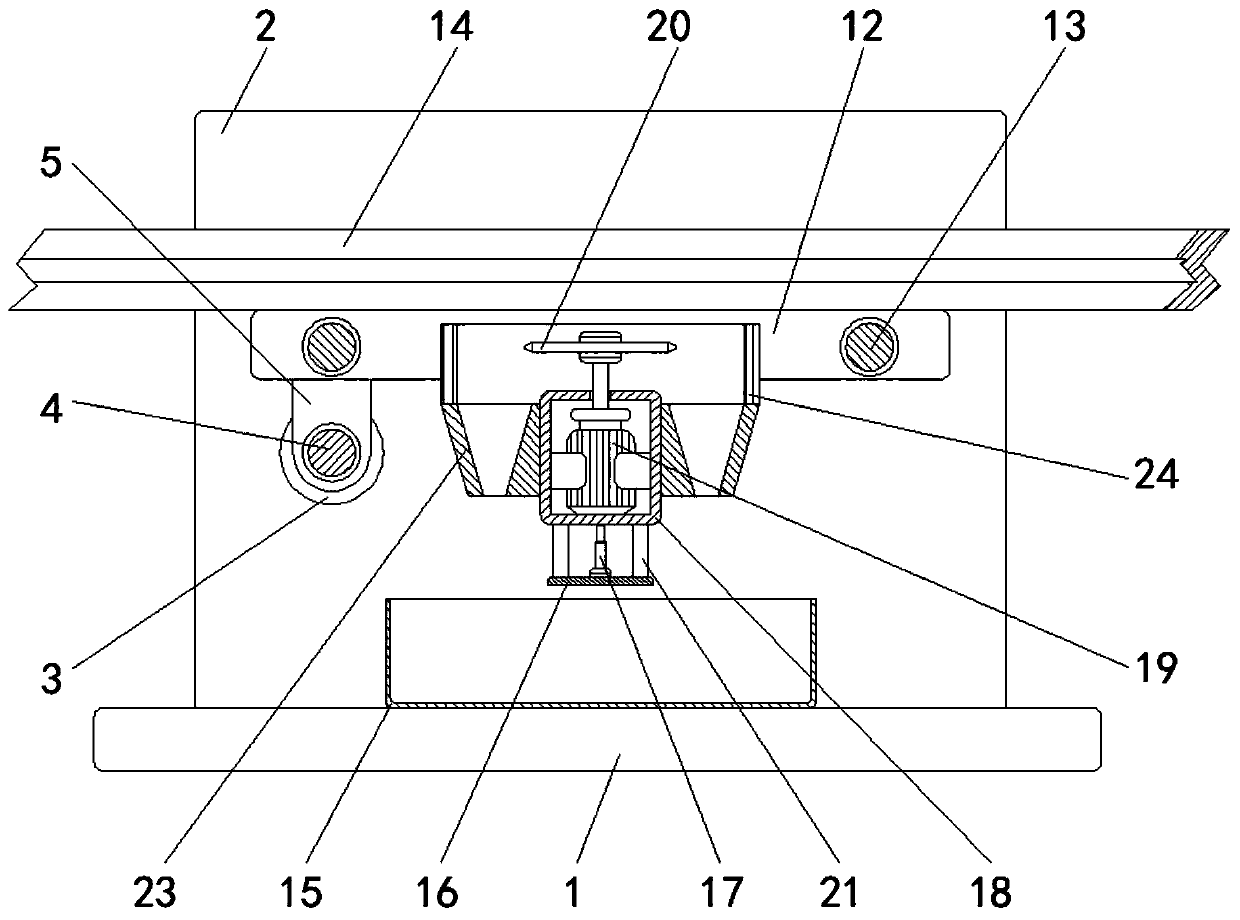

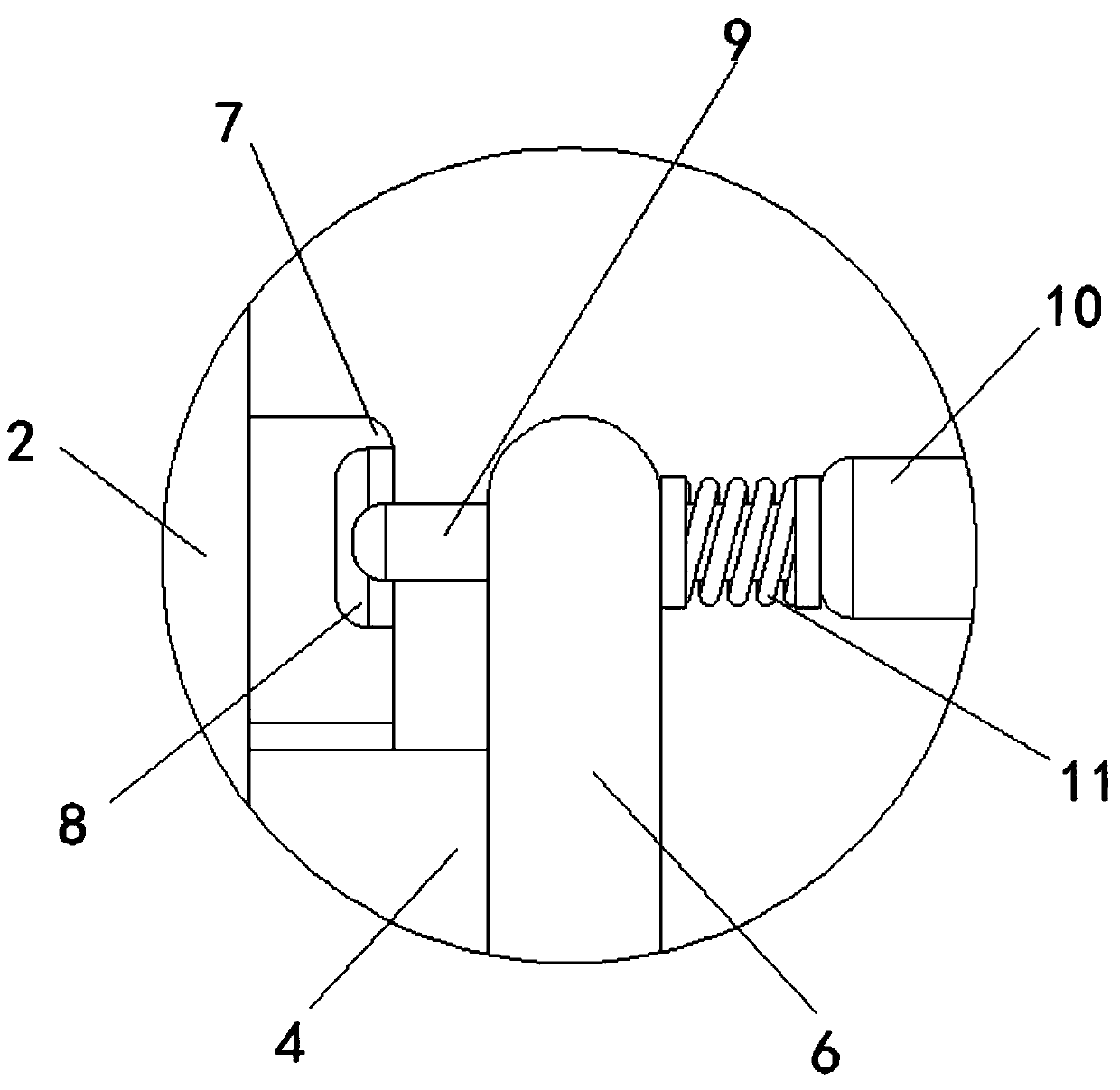

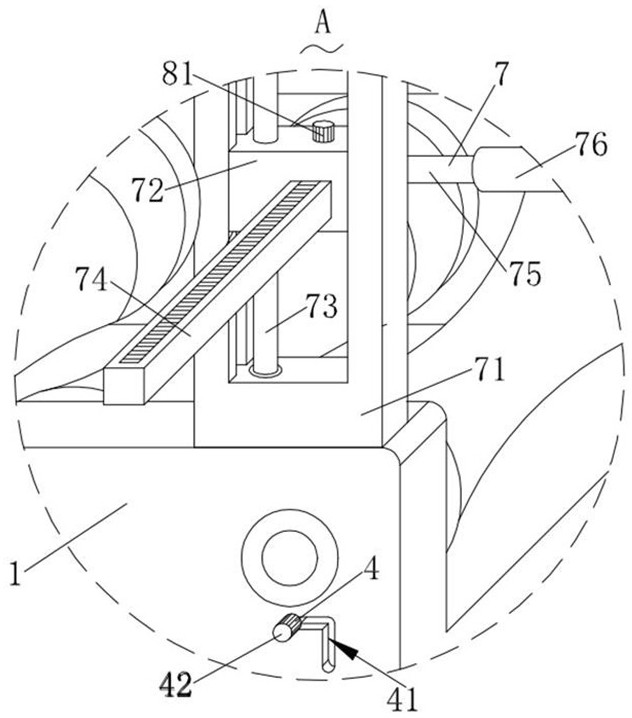

Adjustable pin shearing machine for electronic component production

The invention relates to the technical field of electronic component production equipment, and discloses an adjustable pin shearing machine for electronic component production. The adjustable pin shearing machine comprises a base plate, the top of the base plate is fixedly provided with two side plates, the opposite sides of the side plates are fixedly provided with bearing clamps, a screw rod which penetrates through each side plate and extends to the inside of each bearing clamp is movably arranged on the right side of each side plate, the outer wall of the screw rod is sleeved with a connecting block, a hand wheel is fixedly arranged on the right side of the screw rod, and a limiting disc is fixedly arranged on the right side of each side plate and positioned on the periphery of each screw rod. According to the adjustable pin shearing machine for electronic component production, by starting an electric push rod to stretch and retract, the electric push rod drives a motor and a cutting knife to lift through a case, so that the cutting height of the cutting knife is adjusted, and the effect of simple and convenient adjustment is achieved, so that the adjustable pin shearing machine is suitable for shearing various electronic components of different types, thereby improving the practicability of the adjustable pin shearing machine.

Owner:西安智强科技有限公司

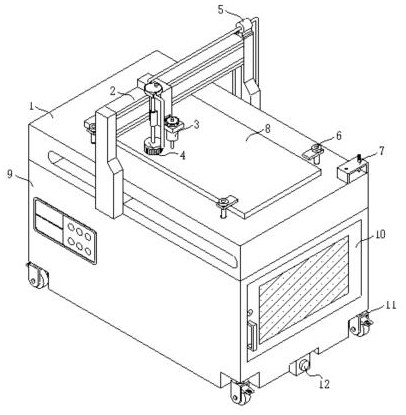

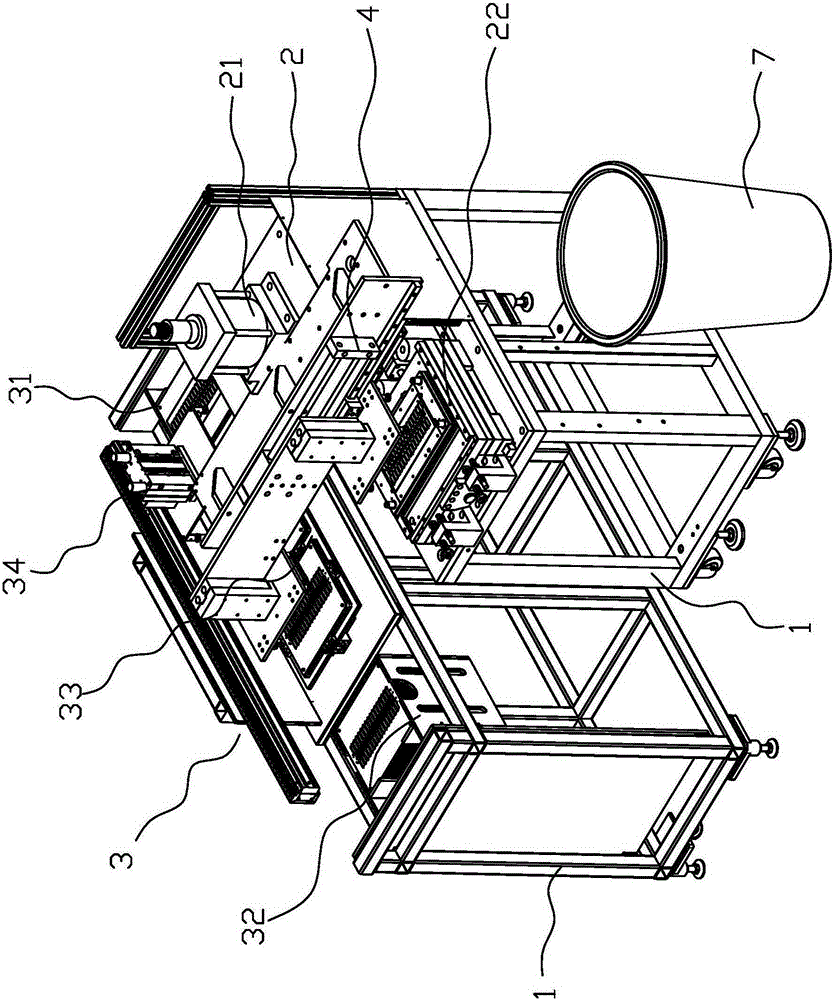

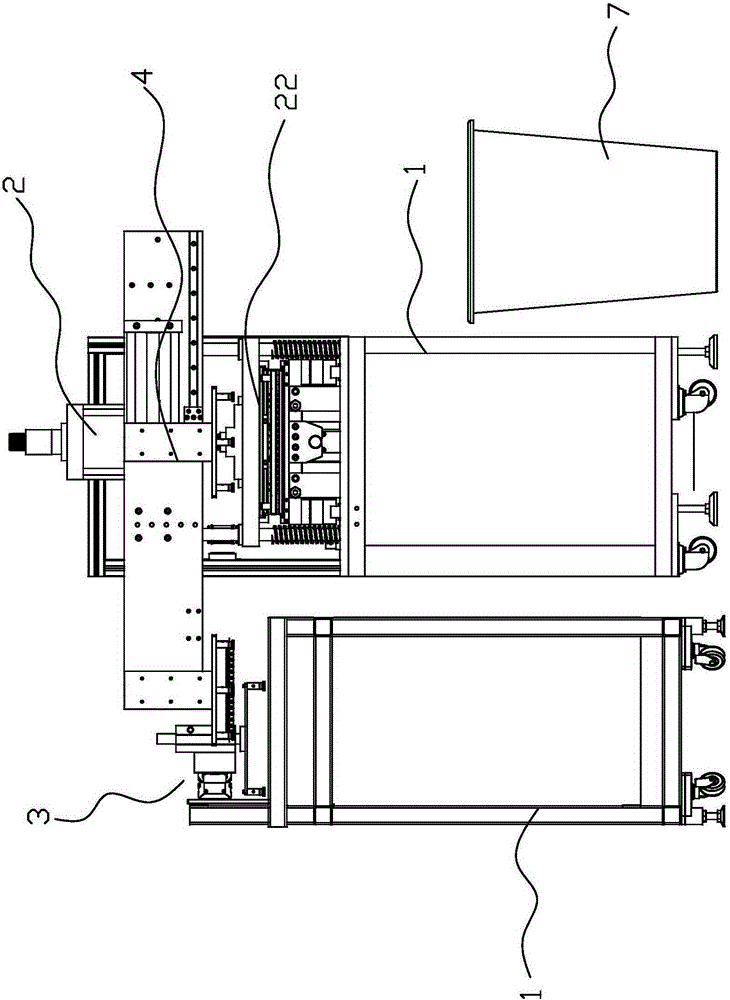

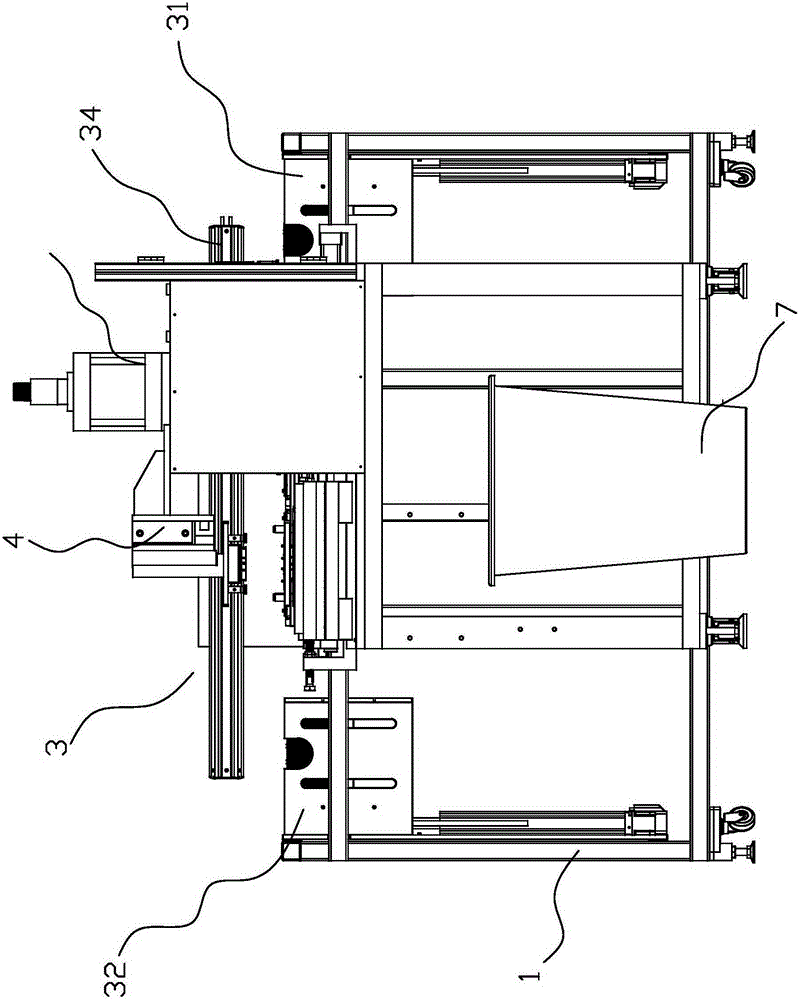

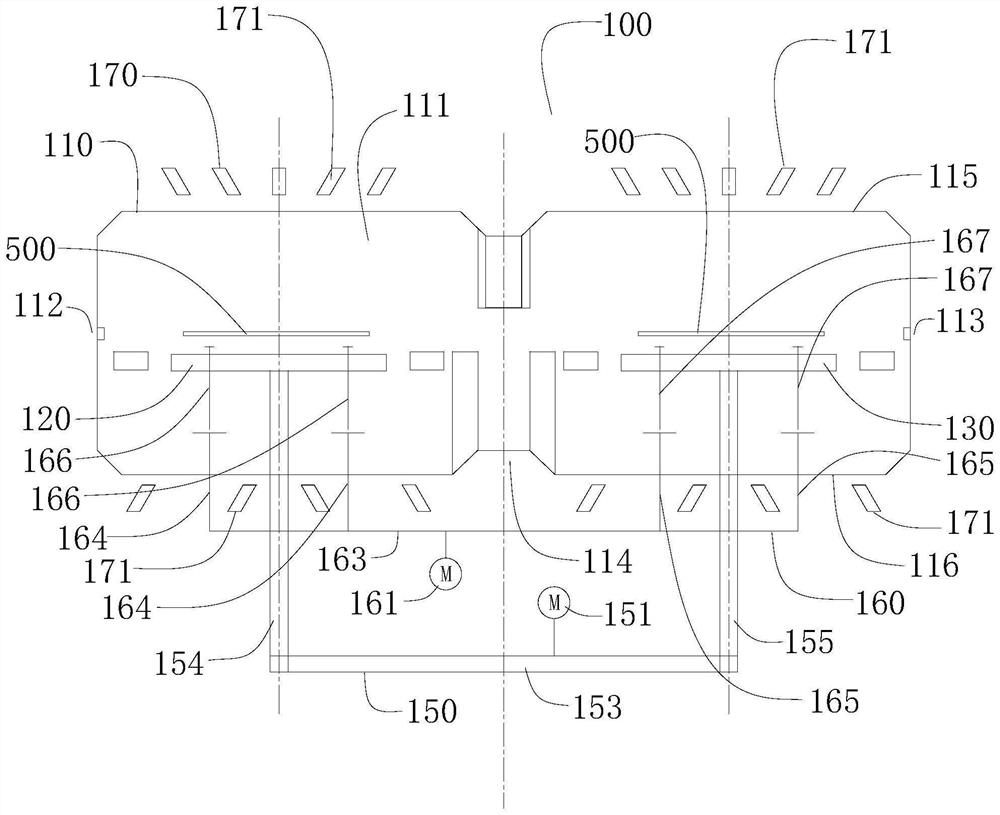

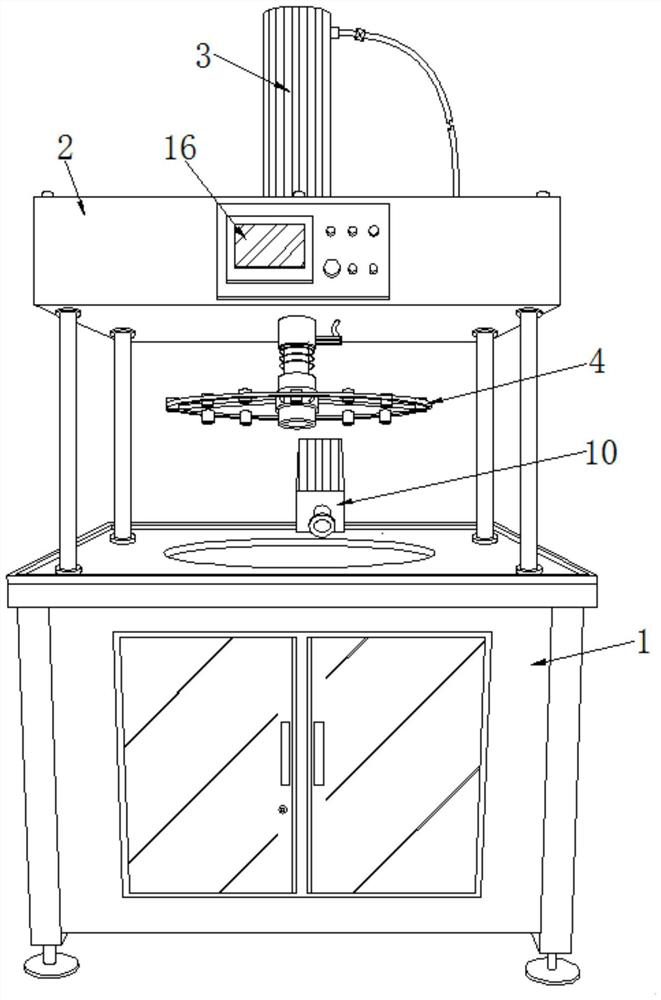

A new fpc punching machine tool with automatic loading and unloading

InactiveCN103496008BIncrease productivityCreate personal hazardMetal working apparatusArticle feedersPunchingEngineering

The invention discloses a novel FPC punching machine tool capable of automatically feeding and discharging a material. The novel FPC punching machine tool can be applied to a bare board section and an SMT section, automatically feeds the material, and after a punched product is accurately placed, scraps are automatically separated. The punching machine tool comprises a machine frame, and a punching machine, a feeding and discharging mechanism and a conveying mechanism are arranged on the machine frame, wherein the conveying mechanism is used for conveying a workpiece to the punching machine from the feeding and discharging mechanism to be punched and conveying the punched product back to the feeding and discharging mechanism. The feeding and discharging mechanism comprises a feeding device and a discharging device which are fixedly arranged on the machine frame and a workpiece translating device located between the feeding device and the discharging device, and a feeding and discharging manipulator device fixed to the machine frame is arranged at the lateral portion of the workpiece translating device. Compared with an existing device, the novel FPC punching machine tool has the advantages of being high in working efficiency, high in safety, good in machined product quality and the like.

Owner:秦倩倩

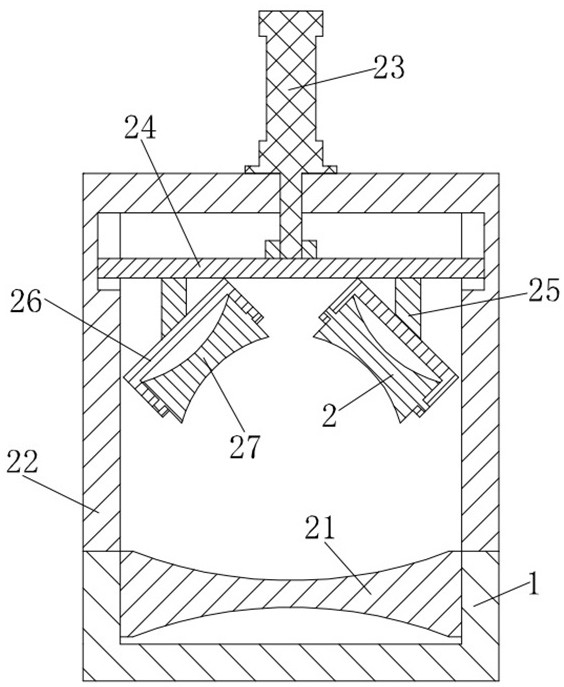

Pressing device for extracting juice from folium artemisiae argyi

InactiveCN113119508AThe effect of automatic smashingCircumstances affecting qualityGrain treatmentsPressesFixed frameEngineering

The invention relates to the technical field of folium artemisiae argyi, and discloses a pressing device for extracting juice from the folium artemisiae argyi. The pressing device comprises a shell, the exterior of the shell is fixedly connected with a feeding port, the interior of the shell is fixedly connected with a photosensitive assembly, the interior of the shell is provided with an electric telescopic rod, and the interior of the shell is fixedly connected with a fixed frame; and a movable frame is slidably connected into the fixed frame, and a rotating shaft is rotatably connected into the fixed frame. Through mutual cooperation of the feeding port, the photosensitive assembly, the electric telescopic rod, the fixed frame, the movable frame, the rotating shaft, a first rotating disc, a connecting frame, a pressing plate, a telescopic rod and a movable filter screen, the device can automatically detect the amount of the folium artemisiae argyi, when the amount reaches a certain amount, an inlet is controlled to be closed, and the situation that in the juice extraction process, the juice quality is influenced due to the fact that dust enters inside is avoided, so that the effects of improving the juice quality and automatically mashing the folium artemisiae argyi are achieved.

Owner:江永光

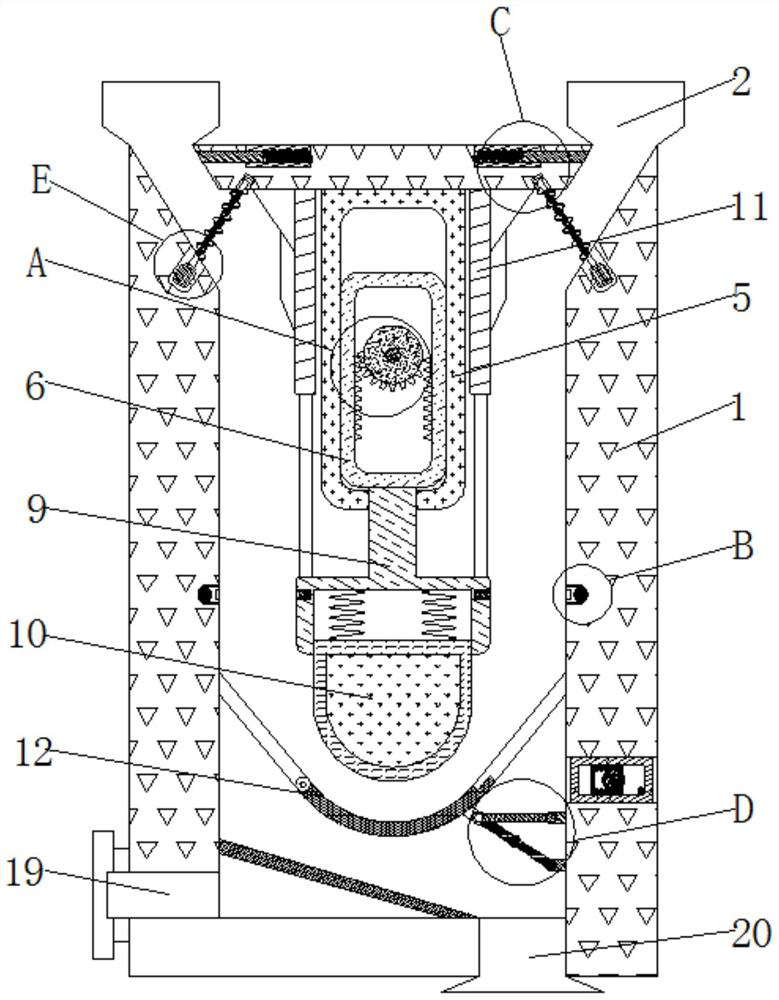

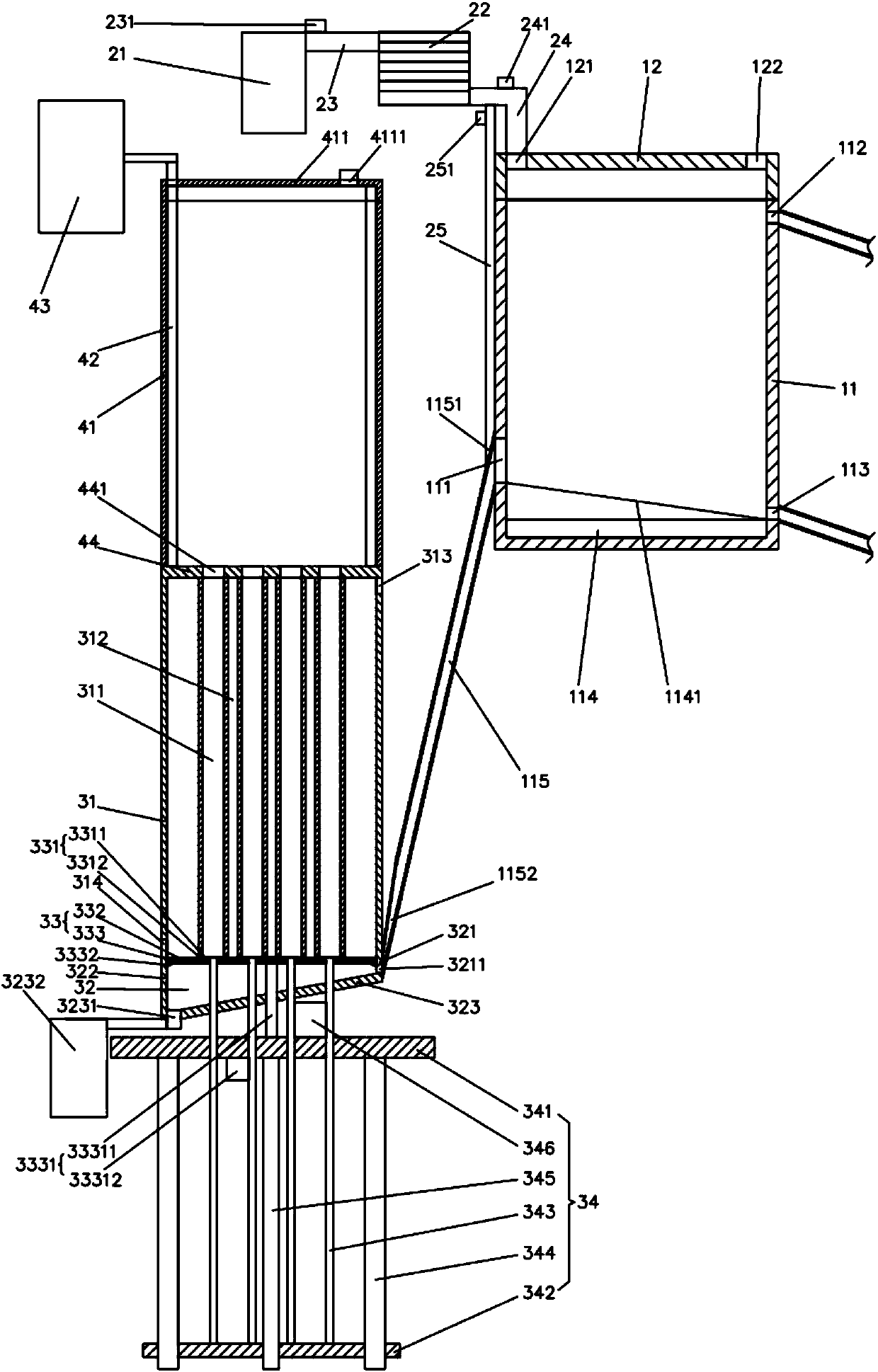

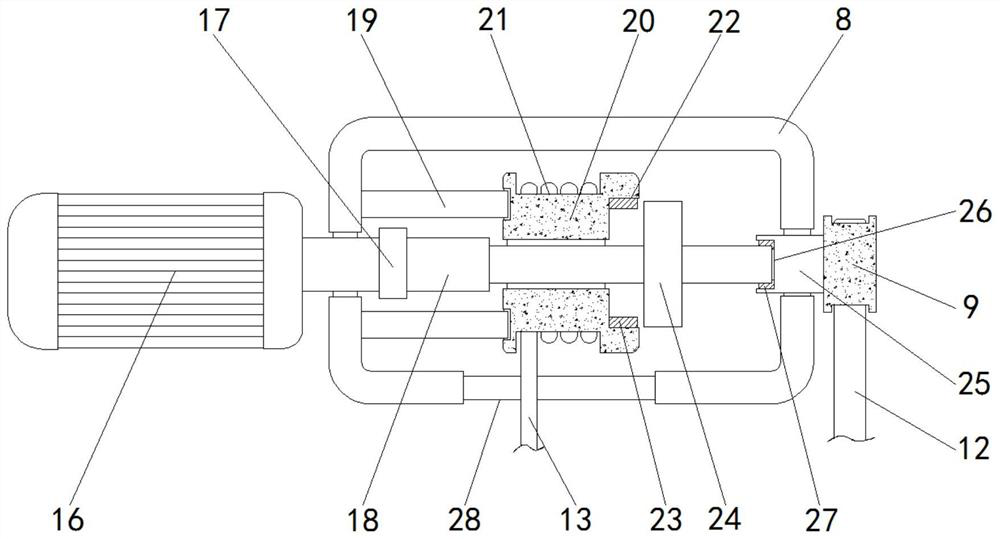

Smelting equipment for fusion casting of aluminum rod applied to aluminum profile

ActiveCN108048670AGuaranteed stabilityGuaranteed circulationMolten metal conveying equipmentsSmelting processNitrogen

The invention discloses smelting equipment for fusion casting of an aluminum rod applied to an aluminum profile. The smelting equipment comprises a smelting furnace, a nitrogen blowing device, an aluminum rod casting device and an anti-oxidation spraying device. According to the smelting equipment, impurities can be discharged efficiently and completely; in an overall smelting process, nitrogen isused for protecting molten aluminum liquid, and formation of oxide layers inside the cast aluminum rod and on the surface of the cast aluminum rod is prevented; moreover, the nitrogen can apply pressure on the molten aluminum liquid so as to increase the flowing speed, and thus cohesion is prevented and the efficiency is improved; furthermore, the molten aluminum liquid enters an aluminum rod mold pipe from bottom to top so that the relatively light nitrogen is upwards extruded out, the nitrogen is hardly left at some holes and can be discharged completely, and the situation that the qualityof the aluminum rod is affected by air bubbles can be prevented; and furthermore, an anti-oxidation coating on the surface of the aluminum rod can realize anti-oxidation protection for the aluminum rod after casting, so the quality of an aluminum profile product is improved.

Owner:奋安铝业股份有限公司

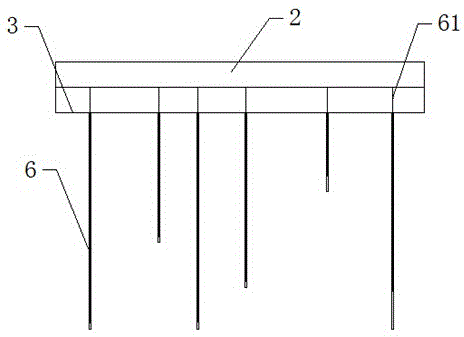

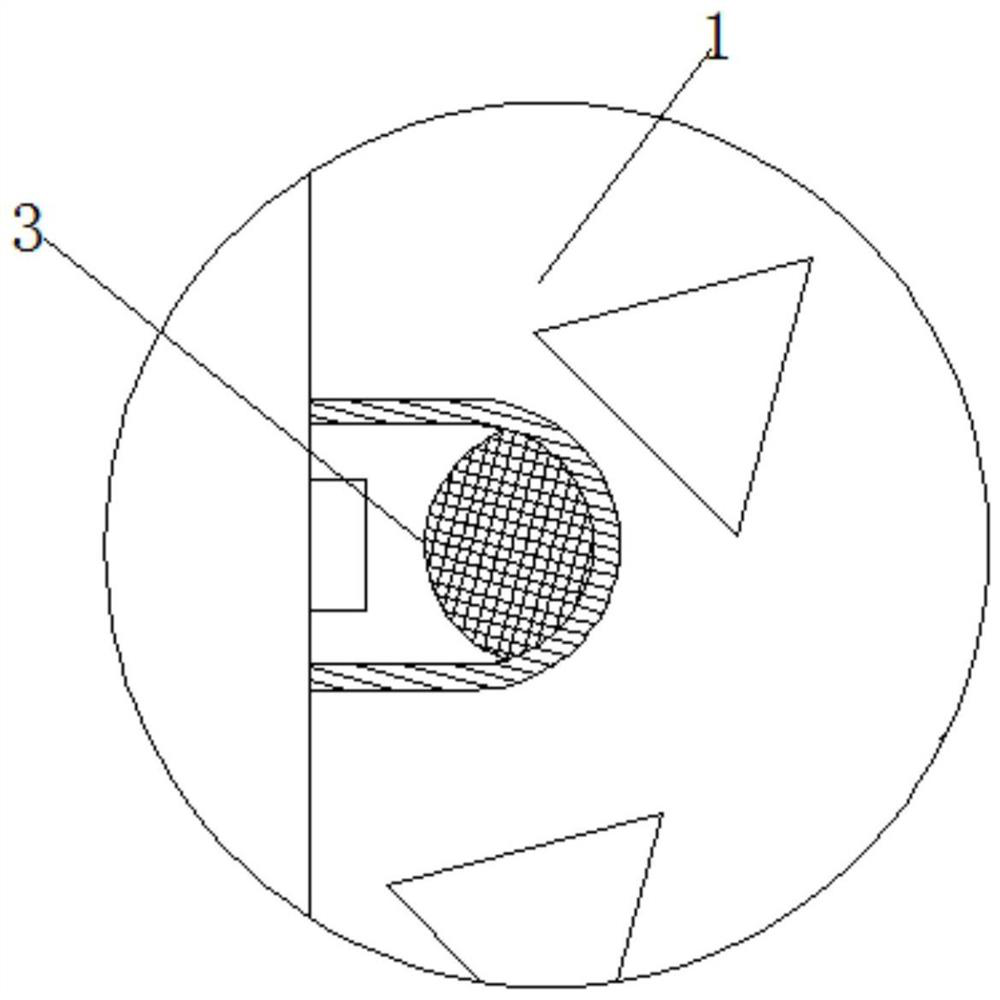

Ultraviolet irradiation mechanism for optical fiber curing

ActiveCN113680620ASame intensityImprove the defect of uneven strengthPretreated surfacesCoatingsPhoto irradiationUltraviolet lights

The invention relates to an ultraviolet irradiation mechanism for optical fiber curing. The ultraviolet irradiation mechanism comprises an irradiation supporting assembly, a rotating assembly, a driving assembly and a light source assembly used for emitting ultraviolet light, wherein the rotating assembly is rotatably installed on the irradiation supporting assembly; the driving assembly is fixed to the irradiation supporting assembly; the driving assembly is in transmission connection with the rotating assembly, and used for driving the rotating assembly to rotate; and the light source assembly is fixedly installed on the rotating assembly, and a curing space used for optical fiber curing is arranged in the middle of a rotating track where the rotating assembly and the light source assembly are rotated. The ultraviolet irradiation mechanism has the effect of overcoming the defect that the ultraviolet irradiation intensity of the optical fiber in all directions is not uniform.

Owner:TAKFLY COMM

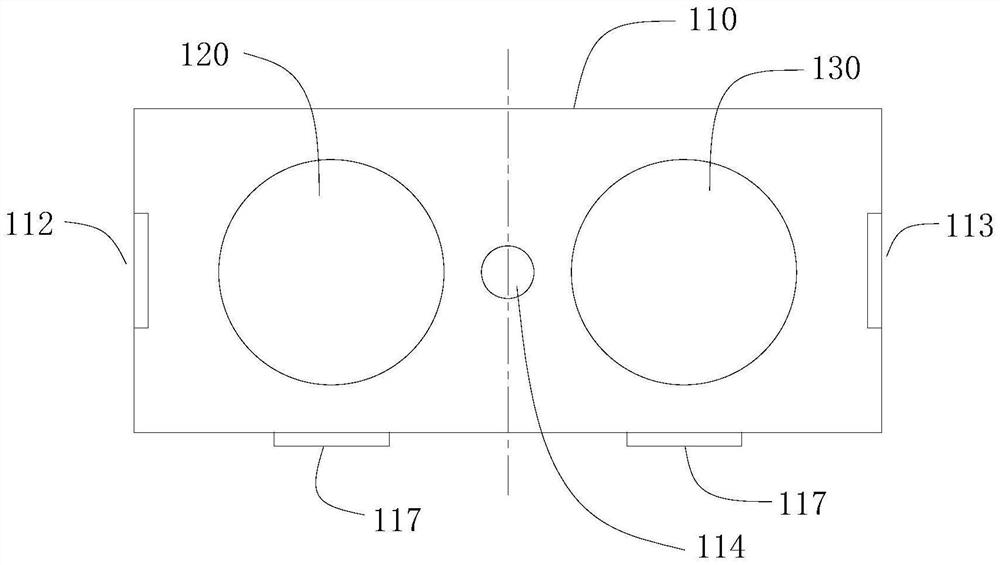

Energy-saving and environment-friendly festoon drying device for use in clothing production

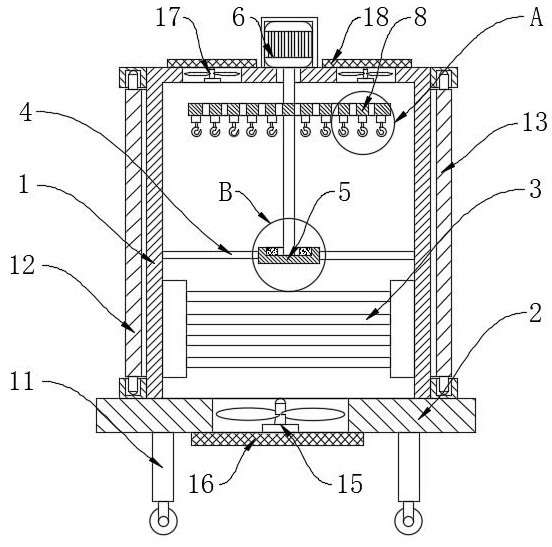

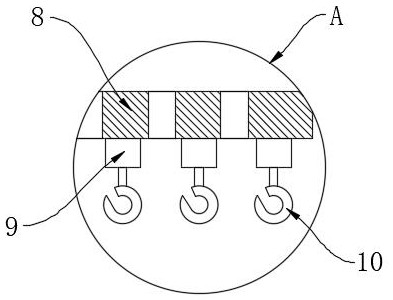

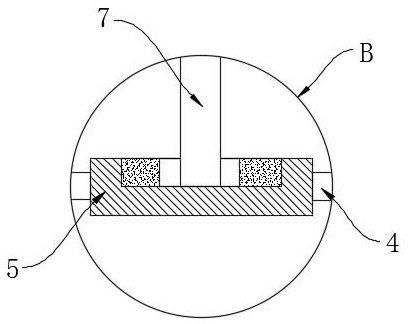

InactiveCN111692864AEvenly heatedCircumstances affecting qualityDrying gas arrangementsDrying chambers/containersElectric machineEngineering

The invention discloses an energy-saving and environment-friendly festoon drying device for use in cloth production. The energy-saving and environment-friendly festoon drying device comprises a cylindrical drying barrel, wherein a first mounting base and a second mounting base are fixedly arranged on the inner wall of the cylindrical drying barrel respectively; an electric heating stick is fixedlyarranged on the side, far away from the inner wall of the cylindrical drying barrel, of the first mounting base; a rotating motor is fixedly arranged on the inner wall of a fixing box; the end, far away from the lower surface of the rotating motor, of an output shaft is fixedly connected with a rotating rod; and a clothing suspending disk is arranged on the surface of the rotating rod. In the energy-saving and environment-friendly festoon drying device, the rotating motor, the rotating rod, the clothing suspending disk, a blowing fan, the electric heating stick and an induced draft fan are provided, and clothing can be suspended on the clothing suspending disk and rotationally dried through the rotating motor during drying, so that the clothing can be heated uniformly during drying, and the influence on the clothing quality due to nonuniform heating of the clothing is avoided.

Owner:徐东清

Melting equipment for melting and casting aluminum rods for aluminum profiles

ActiveCN108048670BGuaranteed stabilityGuaranteed circulationMolten metal conveying equipmentsSmelting processNitrogen

The invention discloses smelting equipment for fusion casting of an aluminum rod applied to an aluminum profile. The smelting equipment comprises a smelting furnace, a nitrogen blowing device, an aluminum rod casting device and an anti-oxidation spraying device. According to the smelting equipment, impurities can be discharged efficiently and completely; in an overall smelting process, nitrogen isused for protecting molten aluminum liquid, and formation of oxide layers inside the cast aluminum rod and on the surface of the cast aluminum rod is prevented; moreover, the nitrogen can apply pressure on the molten aluminum liquid so as to increase the flowing speed, and thus cohesion is prevented and the efficiency is improved; furthermore, the molten aluminum liquid enters an aluminum rod mold pipe from bottom to top so that the relatively light nitrogen is upwards extruded out, the nitrogen is hardly left at some holes and can be discharged completely, and the situation that the qualityof the aluminum rod is affected by air bubbles can be prevented; and furthermore, an anti-oxidation coating on the surface of the aluminum rod can realize anti-oxidation protection for the aluminum rod after casting, so the quality of an aluminum profile product is improved.

Owner:奋安铝业股份有限公司

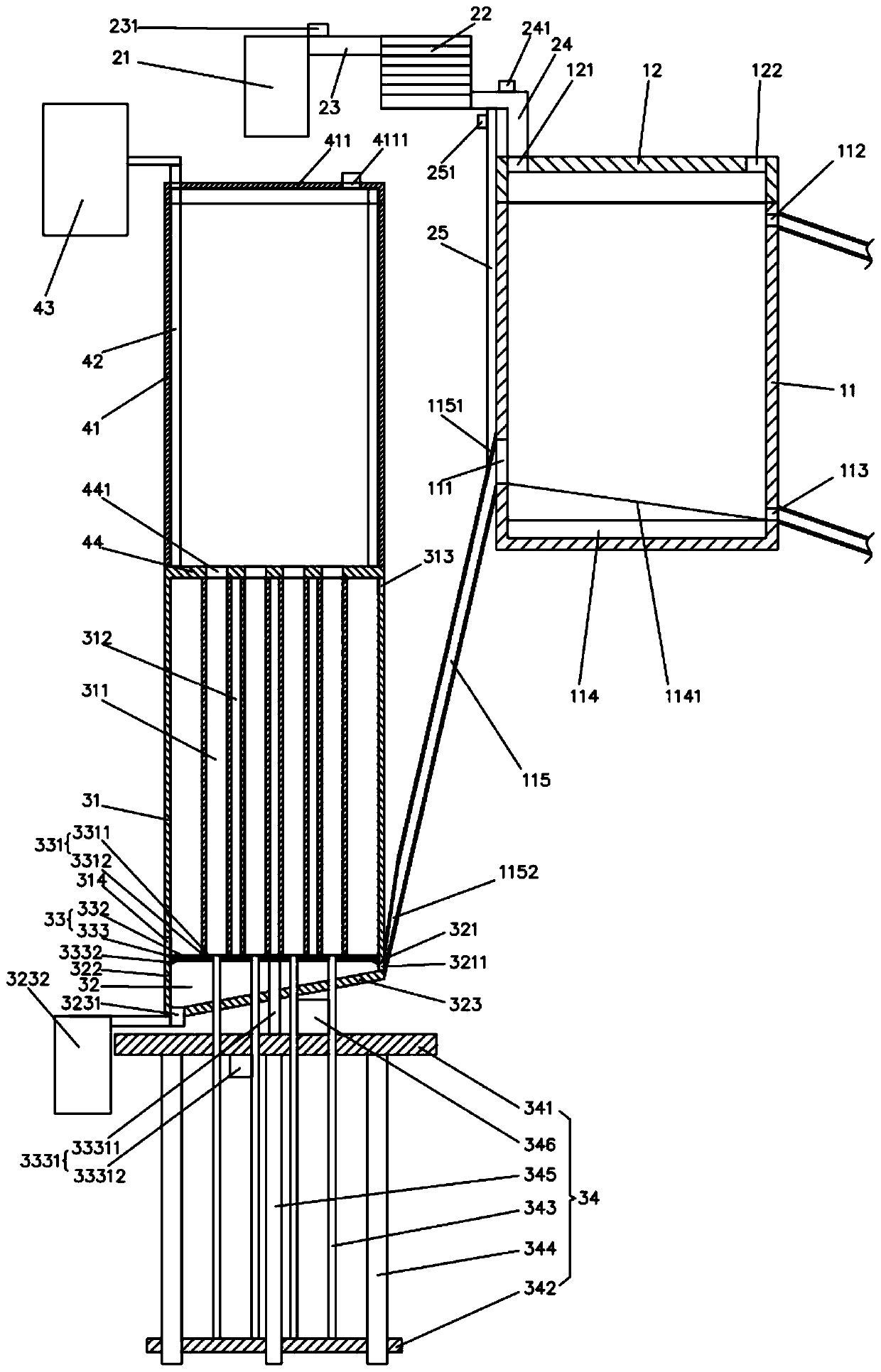

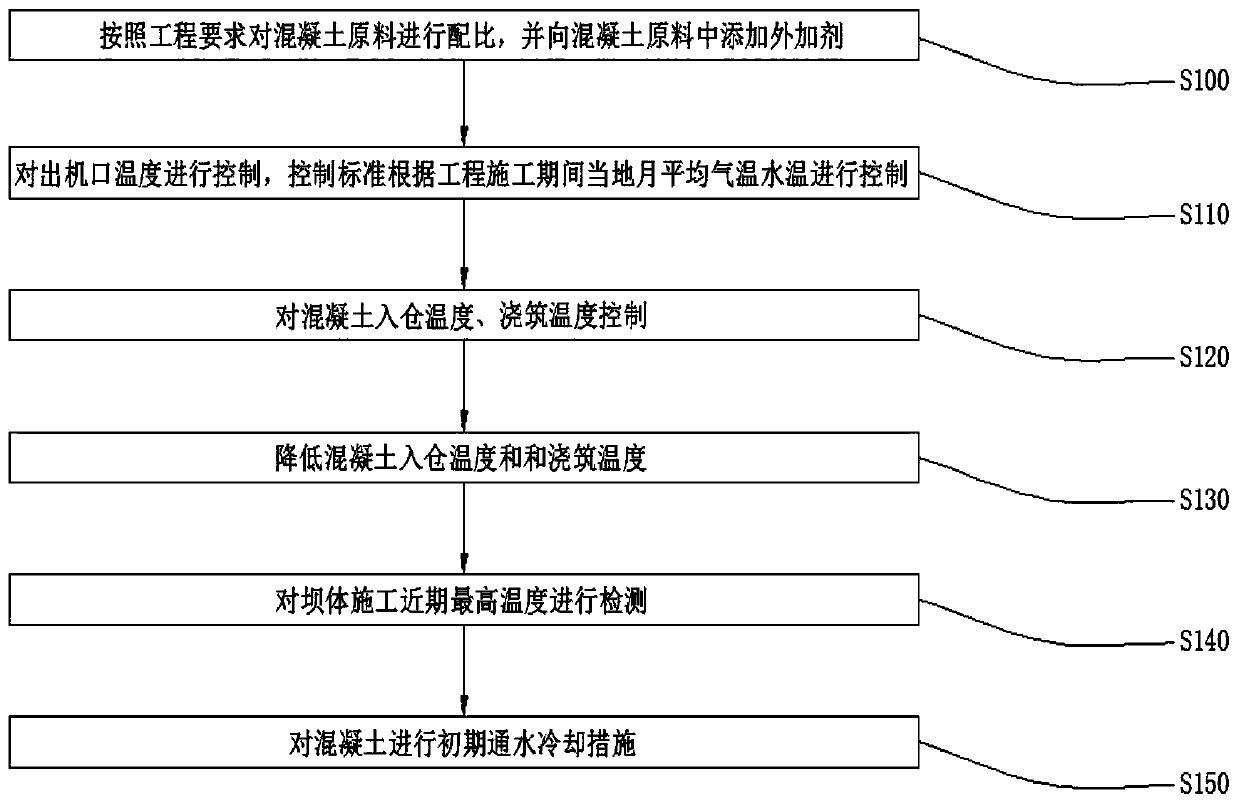

Main dam project concrete temperature control process

InactiveCN110318399ACircumstances affecting qualityBarrages/weirsFoundation engineeringTemperature controlEngineering

The invention discloses a main dam project concrete temperature control process. The process comprises the following steps of S100, proportioning concrete raw materials according to project requirements and adding additives in the concrete raw materials; S110, controlling the outlet temperature according to the local monthly average air temperature and water temperature in the project constructionperiod; S120, controlling the concrete placement temperature and casting temperature; S130, reducing the concrete placement temperature and the casting temperature; S140, detecting the recent highesttemperature of the dam construction; and S150, carrying out an initial water cooling measure on the concrete. Through effectively cooling the raw materials of the concrete and detecting the outlet temperature, the concrete placement temperature and the casting temperature in real time, corresponding temperature measures are carried out on the concrete temperature, so that the temperature of the concrete accords with the project standards, thereby effectively avoiding the concrete temperature from being too high to cause the condition of influencing the dam quality.

Owner:SINOHYDRO ENG BUREAU 4

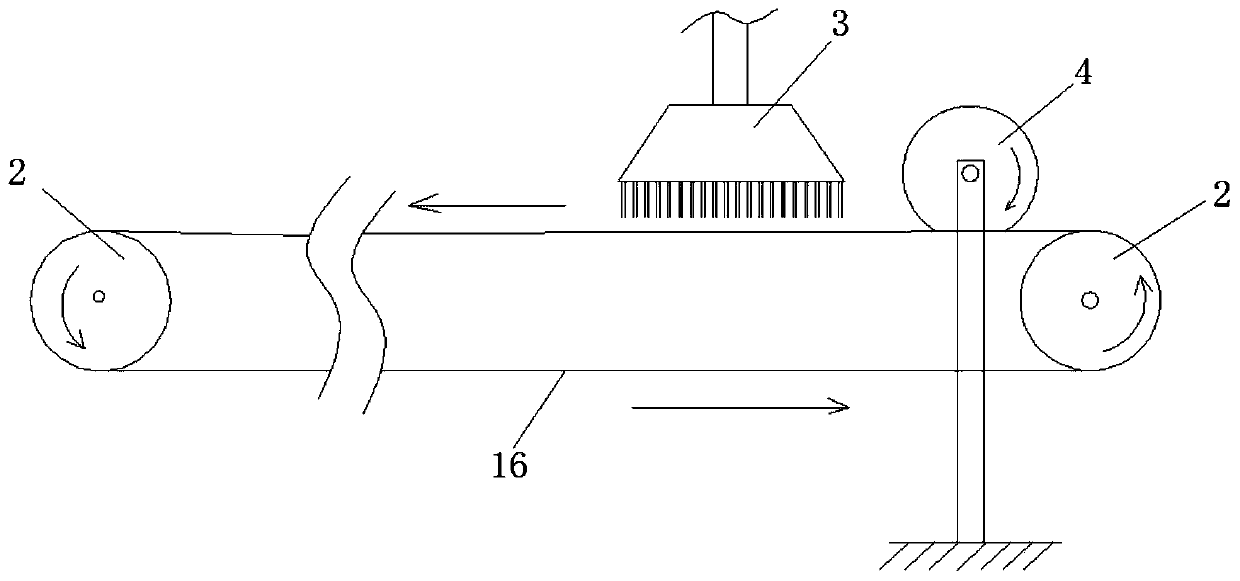

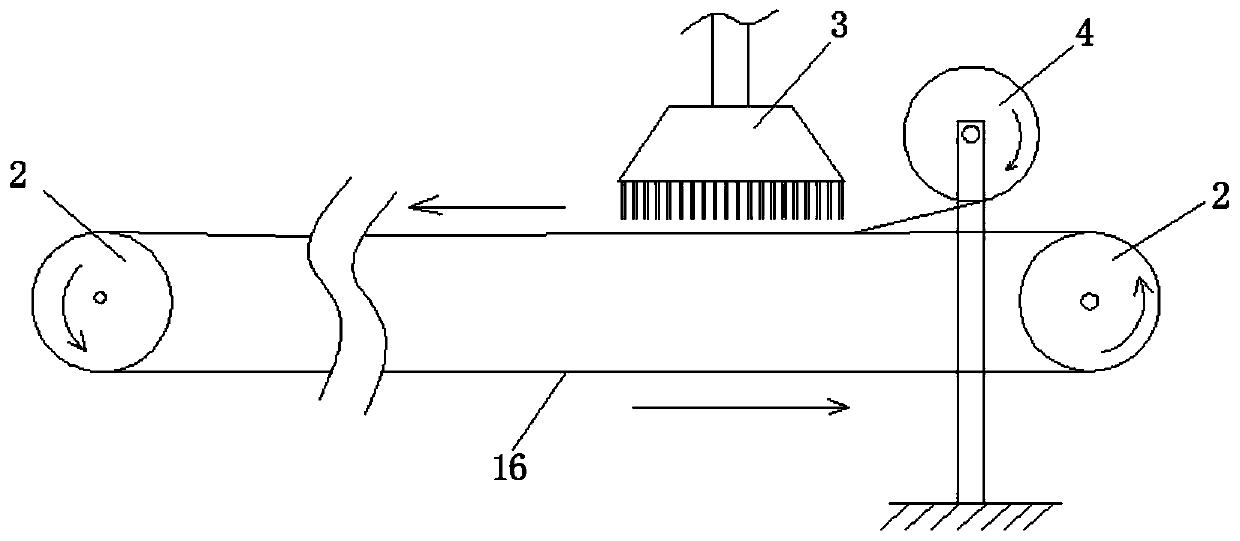

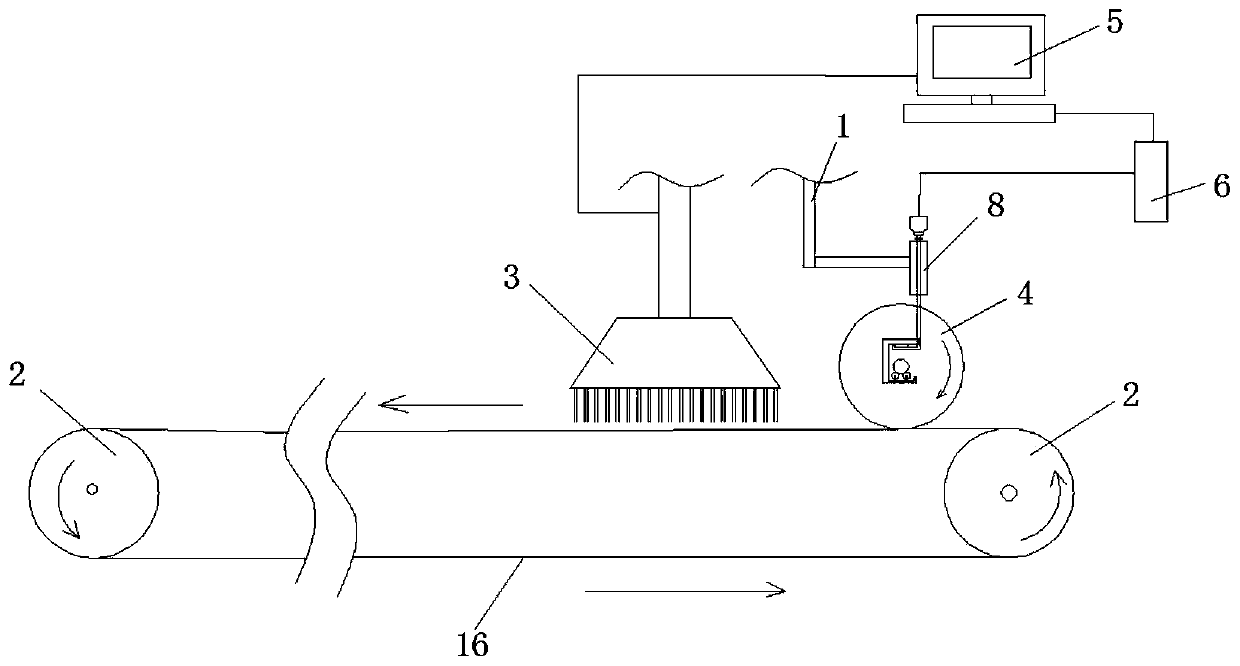

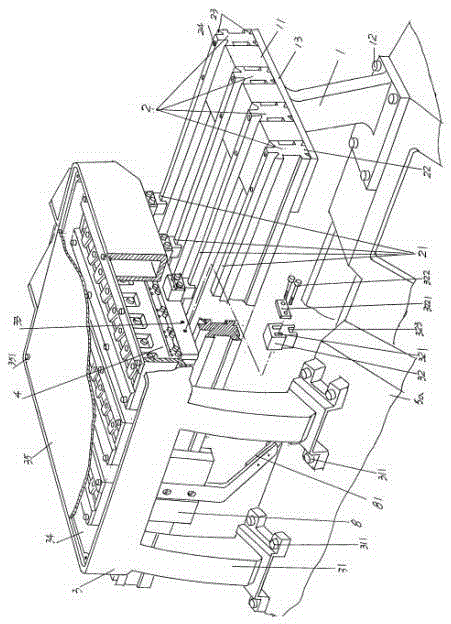

Paper making felt needle machine unrolling device

InactiveCN110203730APrevent fallingStable structureNeedling machinesWebs handlingPulp and paper industryPressure sensor

The invention belongs to the technical field of paper making felt manufacturing equipment, and particularly relates to a paper making felt needle machine unrolling device. The paper making felt needlemachine unrolling device comprises a rack, cloth guiding rollers, needle mechanisms and a first rough roll roller for front face unrolling. A computer, a PLC, a first pressure sensor and a first lifting machine are further included. The cloth guiding rollers and the needle mechanisms are arranged on the rack, and the needle mechanisms and the PLC are connected with the computer. The PLC is electrically connected with the first pressure sensor and the first lifting machine, the first lifting machine is also arranged on the rack, the first rough roll roller is erected at the lifting end of thefirst lifting machine, and the first pressure sensor is arranged between the first rough roll roller and the lifting end of the first lifting machine. Through the paper making felt needle machine unrolling device, the situation that the first rough roll roller is suspended or extruded on a base net, and consequently the rough roll pavement quality is influenced can be effectively avoided, and therough roll pavement quality is improved.

Owner:SICHUAN VANOV TECH FABRIC

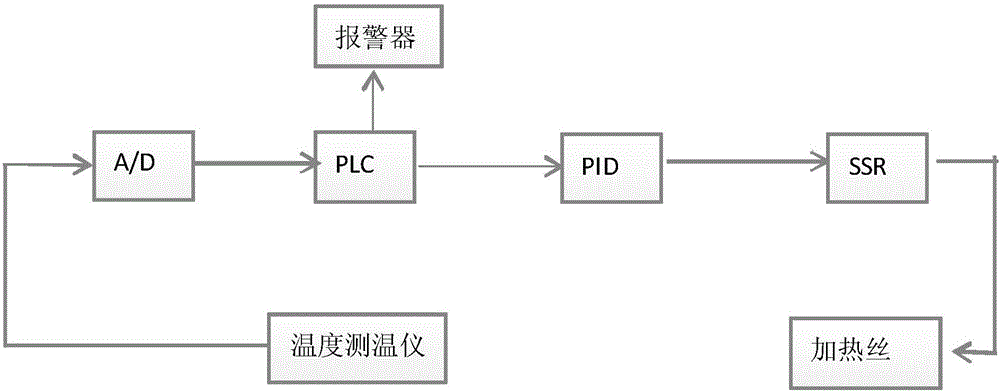

Temperature control system suitable for industrial 3D printer

InactiveCN106444918ACircumstances affecting qualityImprove real-time performanceAuxillary controllers with auxillary heating devicesTemperature controlControl system

The invention discloses a temperature control system suitable for an industrial 3D printer, belonging to the technical field of the 3D printer. The temperature control system can quickly reach the setting temperature of the industrial 3D printer and stabilize as well as maintain the temperature in a forming cabin. The temperature control system comprises a thermodetector, an AD conversion module, a PLC (Programmable Logic Controller), a PID control module and a solid relay. The situations of unstable temperature control, ultra-long preheating time or failure in reaching the setting temperature of the present 3D printing equipment and even the situation of influencing the quality of the printed workpiece can be avoided, the temperature control system is suitable for metallic and nonmetallic industrial 3D printers and the instantaneity and the stability of the temperature system can be promoted.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

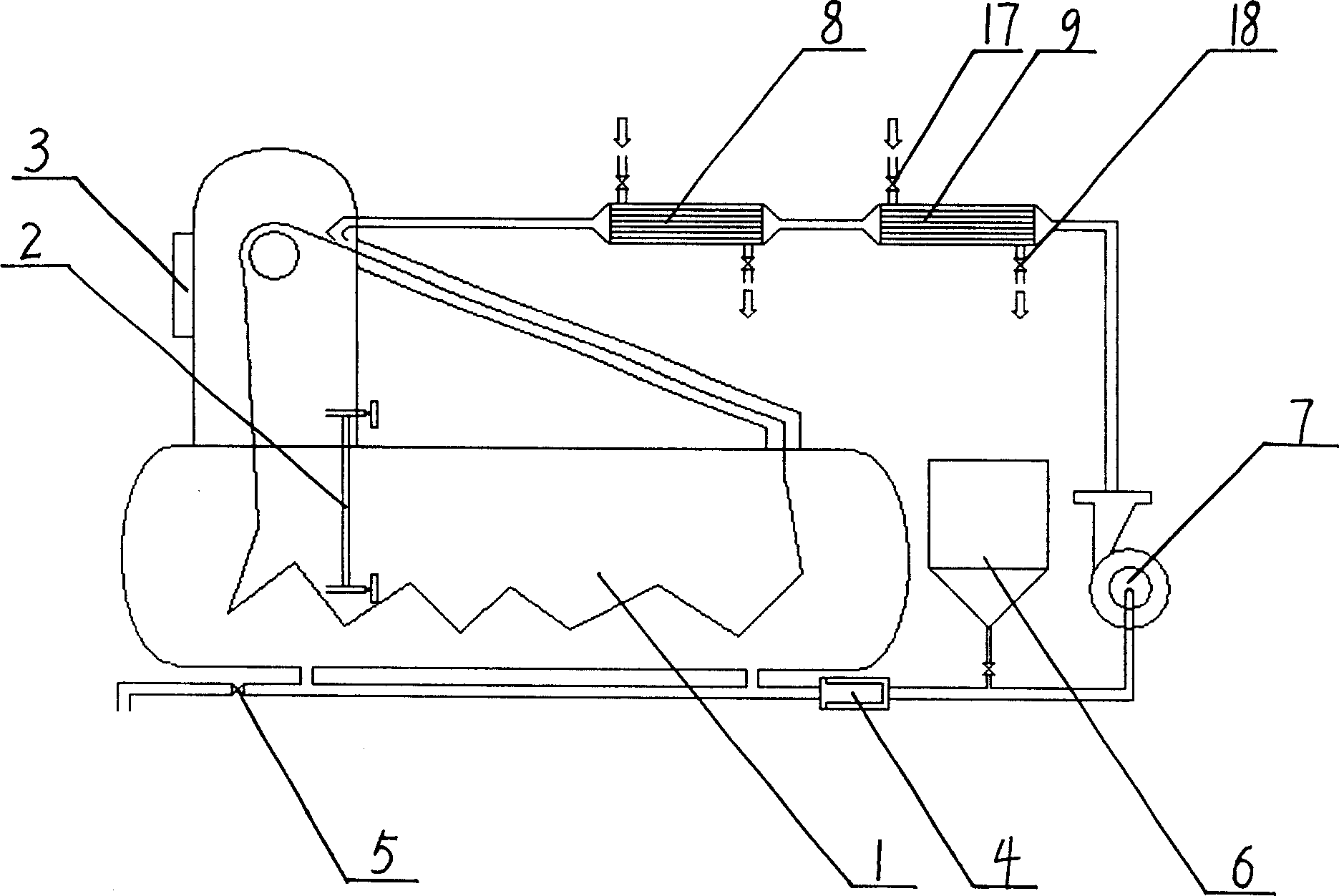

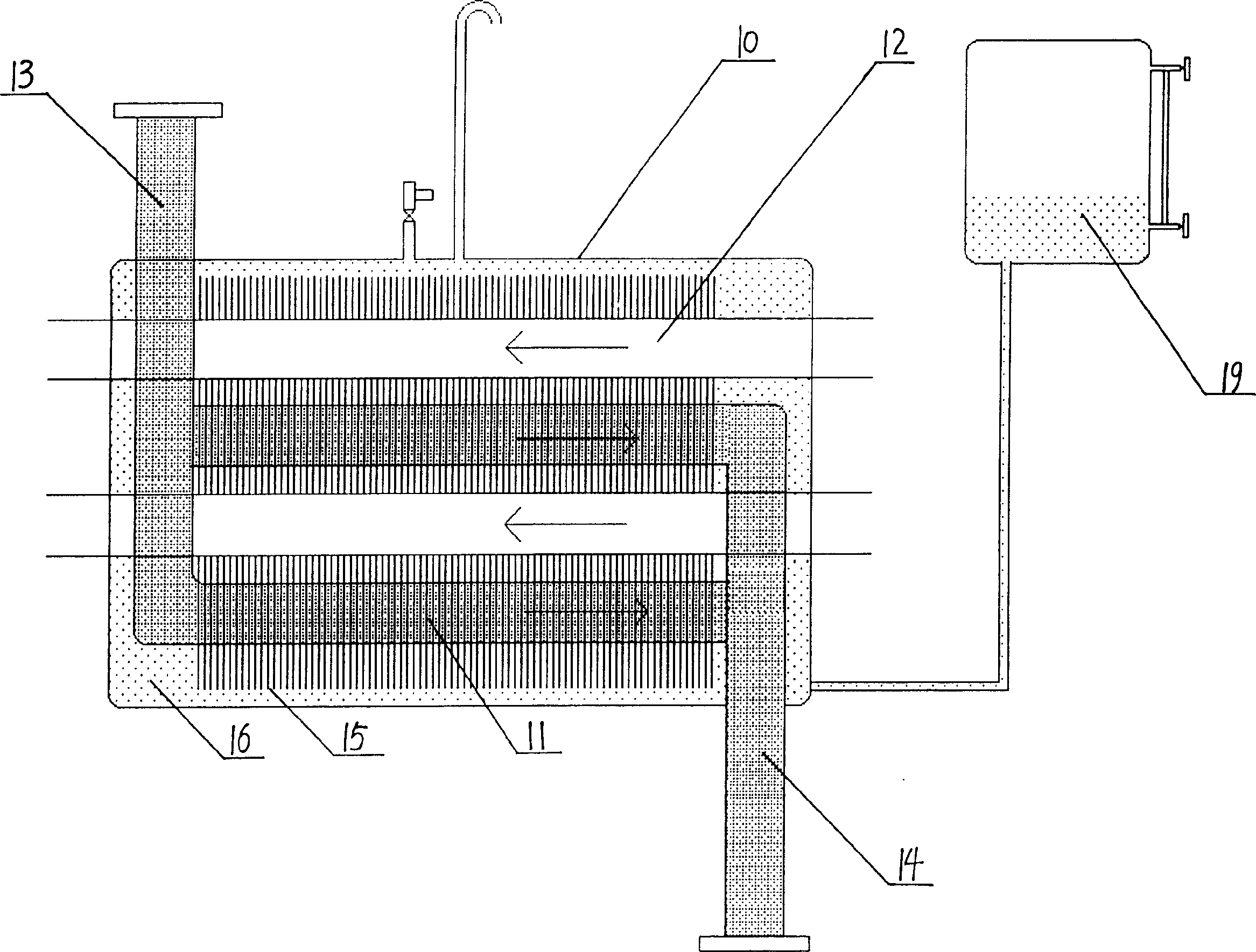

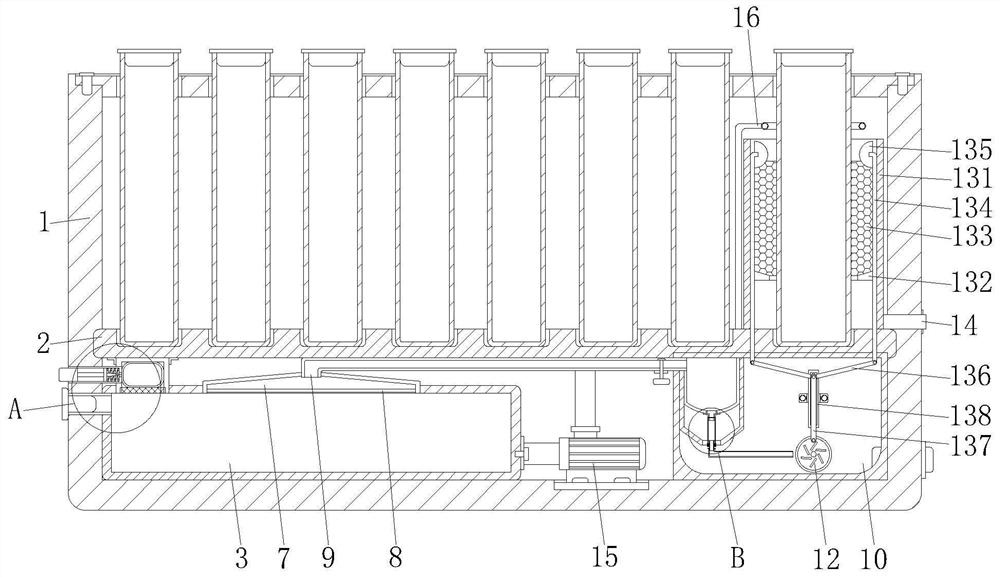

Oil heating type dyeing machine

InactiveCN1284897CReached temperatureCircumstances affecting qualityTextile treatment machine arrangementsWater coolingWater level

The invention relates to a dyeing machine, in particular to an oil-heating dyeing machine, which comprises a cloth dyeing cylinder body, a water level pipe is arranged in the cloth dyeing cylinder body, and a cloth inlet and outlet port is arranged on the upper side of the cloth dyeing cylinder body. The other end of the filter is connected with the feeding barrel and the dye liquor circulating water pump through pipes, and the dyeing cloth vat and the dye liquor circulating water pump are connected through pipes with series water cooling Exchanger and oil heating exchanger. The invention can respectively cool and heat the dye liquor through the water cooling exchanger and the oil heating exchanger connected in series, so as to reach the temperature of the dye liquor required by the process.

Owner:劳关明

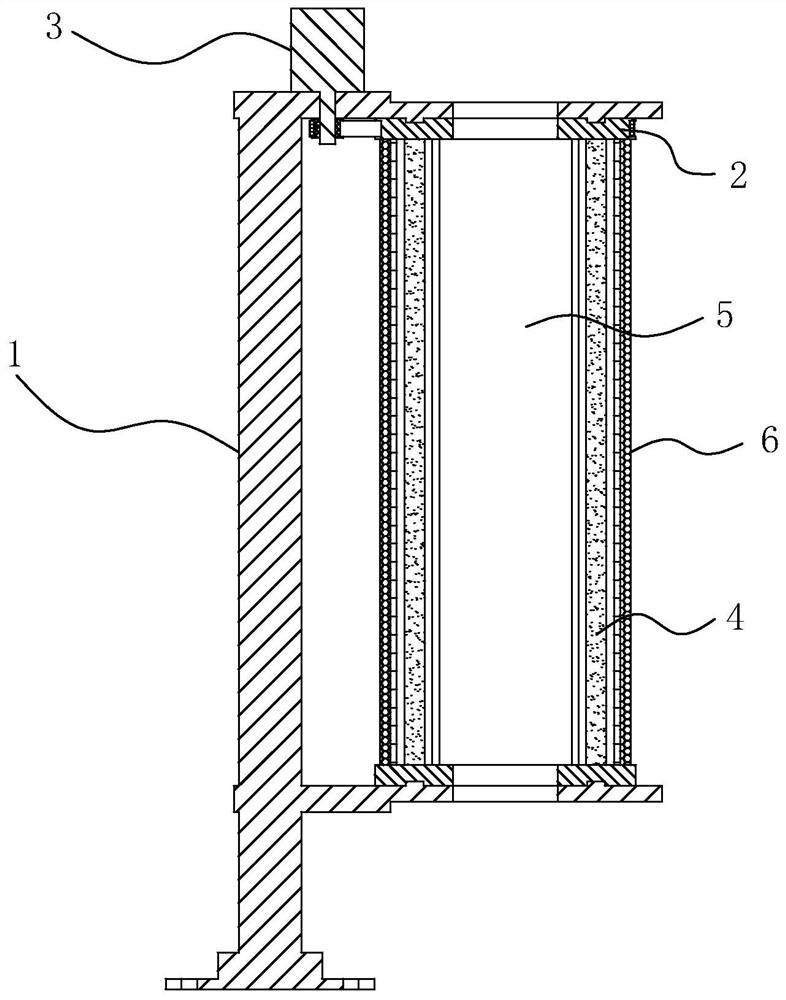

Epitaxial growth apparatus

PendingCN114855271AImprove production efficiencyImprove output efficiencyFinal product manufactureFrom chemically reactive gasesMechanical engineeringMaterials science

Owner:ZHEJIANG QIUSHI SEMICON EQUIP CO LTD

Cooperating structure of skybar device and shuttle changing device of computerized flat knitting machine

The invention provides a fitting structure of a top lever device and a shuttle changing device of a computerized flat knitting machine, and belongs to the technical field of computerized flat knitting machines. The top lever device comprises a pair of shutter guide rail brackets and a group of shuttle guide rails; the shuttle changing device comprises a nose connecting base and a group of shuttle changing control electromagnetic valves; the fitting structure of the top lever device and the shuttle changing device is characterized in that shuttle guide rail attached guide bars are arranged on the surfaces of the upward sides of the group of shuttle guide rails in the length direction respectively, shuttle guide rail limiting sliders are fixed on the front and rear sides of the nose connecting base respectively, and the shuttle guide rail limiting sliders are in sliding fit with the shuttle guide rail attached guide bars. In the process when the shuttle changing control electromagnetic valves moving along with the nose connecting base drive shuttles to move back and forth along the shuttle guide rails, the shuttle guide rails do not, for example, vibrate and shake, so as to ensure that the shuttles driven by the shuttle changing control electromagnetic valves move steadily on the shuttle guide rails and yarns can be accurately fed into a knitting mechanism by the shuttles; therefore, the situation that the quality of the fabrics are finally affected by missed stitch due to inaccurate yarn feeding can be avoided.

Owner:JIANGSU JINLONG TECHNOLOGY CO LTD

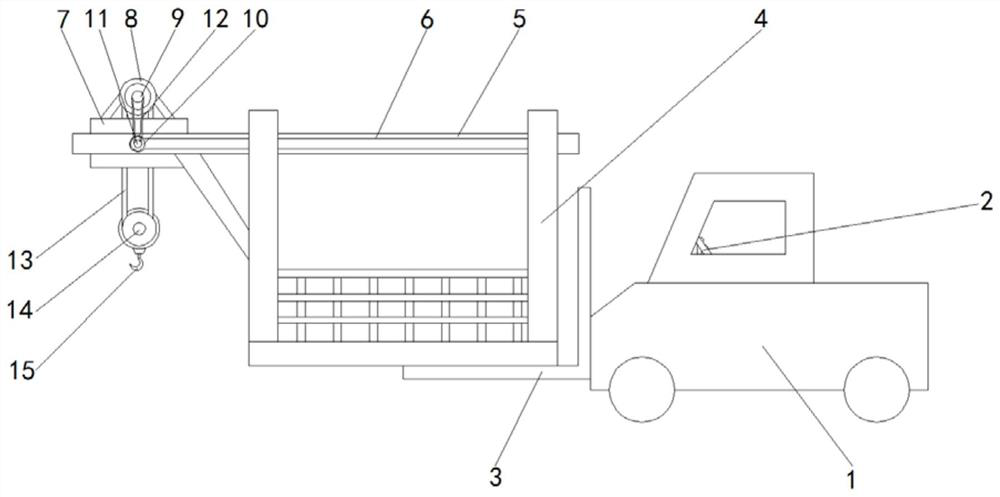

A slag stopper throwing device with one-button operation function

ActiveCN111235344BFast deliveryImprove delivery efficiencyManufacturing convertersDrive shaftEngineering

The invention relates to the technical field of slag stopper dispensing devices, and discloses a slag stopper dispensing device with a one-button operation function, including a car body, a control panel is fixedly installed inside the car body, and the left side of the car body An inserting plate is fixedly installed on the side, and a transport frame is fixedly installed on the top of the left side of the inserting rod. The top of the rod is plugged with a mobile platform, the top of the mobile platform is fixedly installed with a transmission box, and the front of the transmission box is movably equipped with a transmission shaft. The slag stopper dispensing device with one-button operation function can quickly move the slag stopper at the bottom of the transmission rod by setting the transport frame, which improves the efficiency of slag stopper delivery and enables the staff to put the slag stopper more quickly. It avoids the occurrence of injury to the staff caused by being around the high-temperature converter for a long time.

Owner:ANHUI YUNTIAN METALLURGY TECH

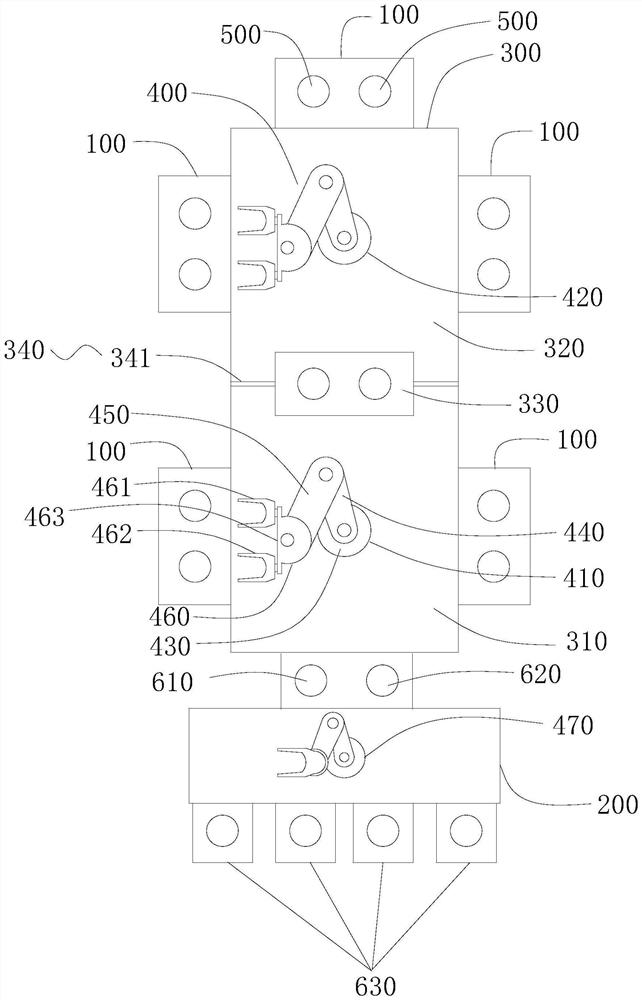

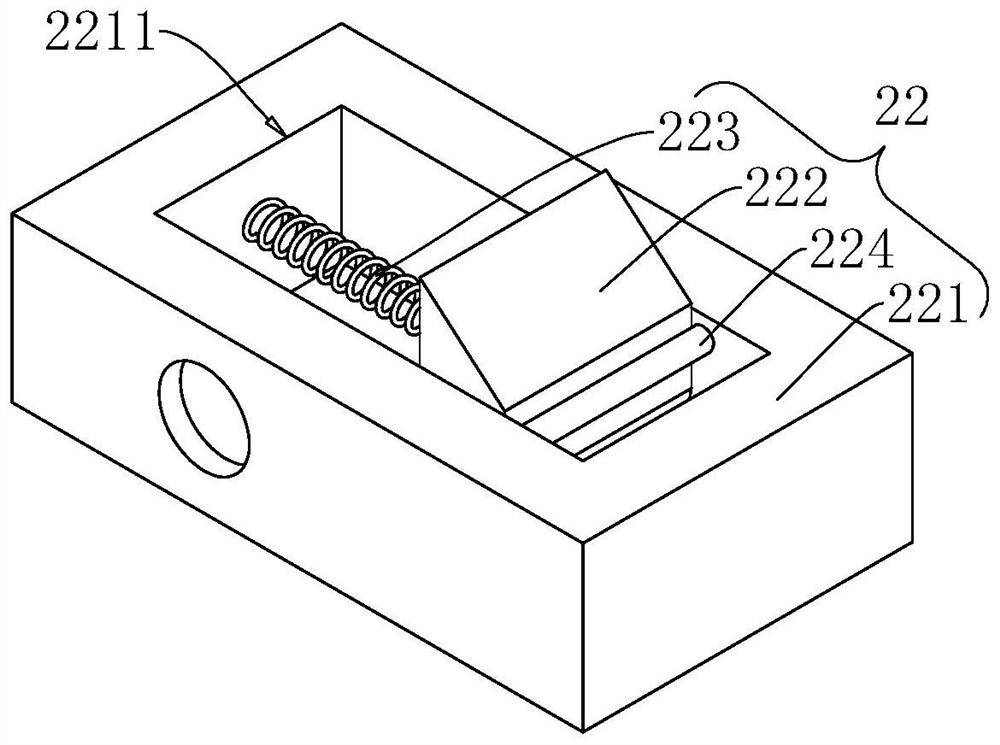

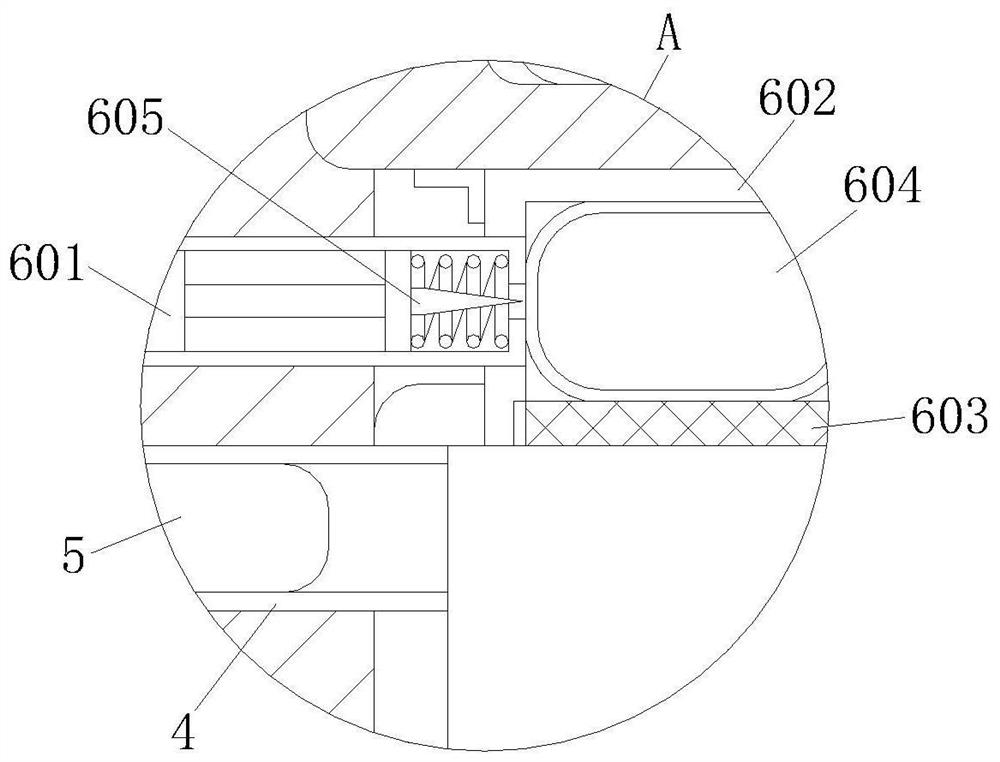

Transmission device applied to pin inserting equipment

ActiveCN114715658ACircumstances affecting qualityPlay the role of positioningContact member assembly/disassemblyNuclear energy generationControl engineeringNatural state

The invention discloses a transmission device applied to pin inserting equipment, which comprises a plurality of positioning modules and a material pushing module, and the positioning modules are arranged along the direction in which the material pushing module pushes a shell to move; the positioning module comprises a plurality of sliding seats and a first positioning mechanism, the sliding seats are provided with sliding grooves allowing the shell to be arranged in a sliding mode, the bottom walls of the sliding grooves are provided with adjusting grooves, the first positioning mechanism is arranged in the adjusting grooves, the first positioning mechanism comprises a moving seat, a positioning block, a reset spring and a limiting rod, and the moving seat is provided with a rotating groove; one end of the positioning block is hinged to the groove wall of the rotating groove, the positioning block can completely rotate into the rotating groove, the limiting rod abuts against one side of the positioning block, the reset spring is connected to the other side of the positioning block, when the reset spring is in a natural state, the end of the positioning block extends into the sliding groove, and the positioning block abuts against the limiting rod. The connector assembly has the effect of improving the product quality of the connector assembly.

Owner:ZHEJIANG DELI CONNECTOR

Solder paste stirring device with solder ball protection structure

InactiveCN112791636AEasy to moveEasy to assemble and disassembleRotating receptacle mixersTransportation and packagingTemperature controlInsulation layer

The invention belongs to the technical field of solder paste preparation, and particularly relates to a solder paste stirring device with a solder ball protection structure. The solder paste stirring device comprises a shell, a protection shell and a first power supply, a hydraulic push rod is fixed below the shell, support legs are connected below the hydraulic push rod, universal wheels are arranged on the right side of the hydraulic push rod, a motor is installed in the protection shell, a transmission shaft is arranged on the left side of the upper portion of the first power source, an inner shell is connected to the upper portion of the transmission shaft, a heat insulation layer is arranged on the surface of the bottom end of the inner shell, a second power source is arranged on the heat insulation layer, an electric heating wire is connected to the right side of the second power source, and a temperature sensor is arranged above the electric heating wire. The solder paste stirring device with the solder ball protection structure is convenient to move, little time and energy are consumed during moving, temperature control can be conducted on the interior during stirring, soldering tin solidification caused by the fact that the internal temperature is too low is avoided, use is convenient, disassembly and assembly are convenient, and little time and energy are consumed during discharging.

Owner:深圳市同方电子新材料有限公司

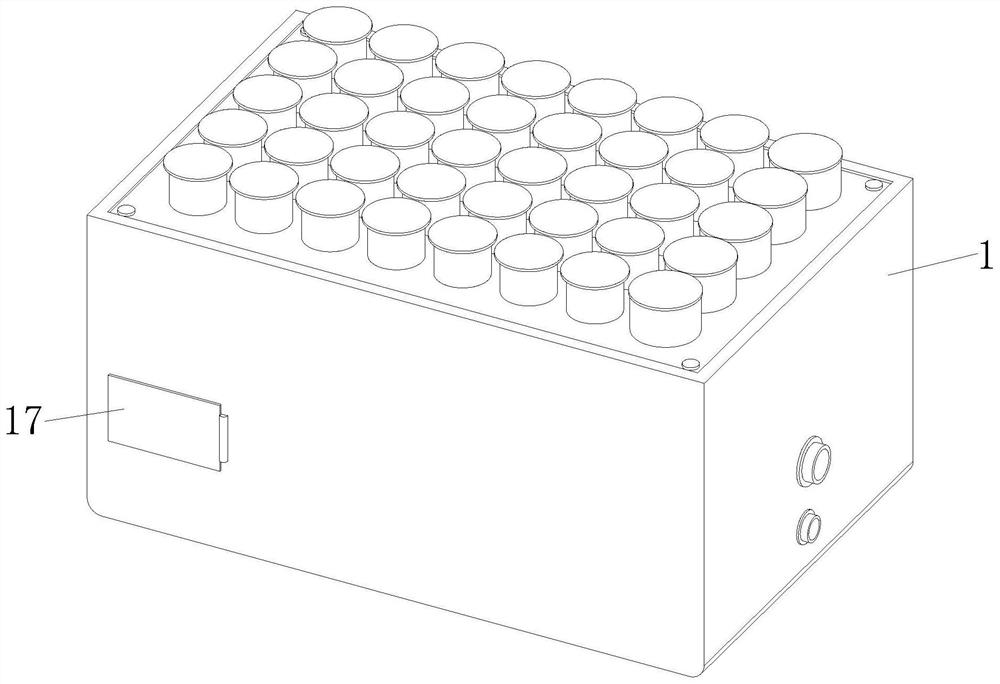

A kit for gene detection of hereditary tumors

ActiveCN110218629BImprove detection efficiencyTo achieve the thawing effectBioreactor/fermenter combinationsBiological substance pretreatmentsWater storageOncology

The invention discloses a kit for genetic detection of hereditary tumors, and relates to the technical field of kits. The kit for the genetic detection of hereditary tumors includes a box body, the box body is fixedly connected with a support plate, and the four sides of the support plate are respectively plugged into the four sides of the inner wall of the box, and the bottom of the support plate is provided with The water storage box, and the bottom of the water storage box is fixedly connected to the left side of the bottom of the box body, the top of the left side of the water storage box is plugged with a water inlet pipe connected to its inner cavity, and the end of the water inlet pipe away from the water storage box runs through the box the left side of the body. The kit for hereditary tumor gene detection uses a heat generating mechanism by pressing the reset button, the water in the water storage box is heated and then discharged onto the ring-shaped sponge in the hollow cylinder, and the ring-shaped sponge absorbs water and expands to closely contact the surface of the solvent bottle , so that the temperature of the water body is transmitted to the solvent through the solvent bottle, and the solvent is heated, so that the precipitate precipitated due to the lower temperature of the solvent gradually melts.

Owner:深圳人体密码基因科技有限公司

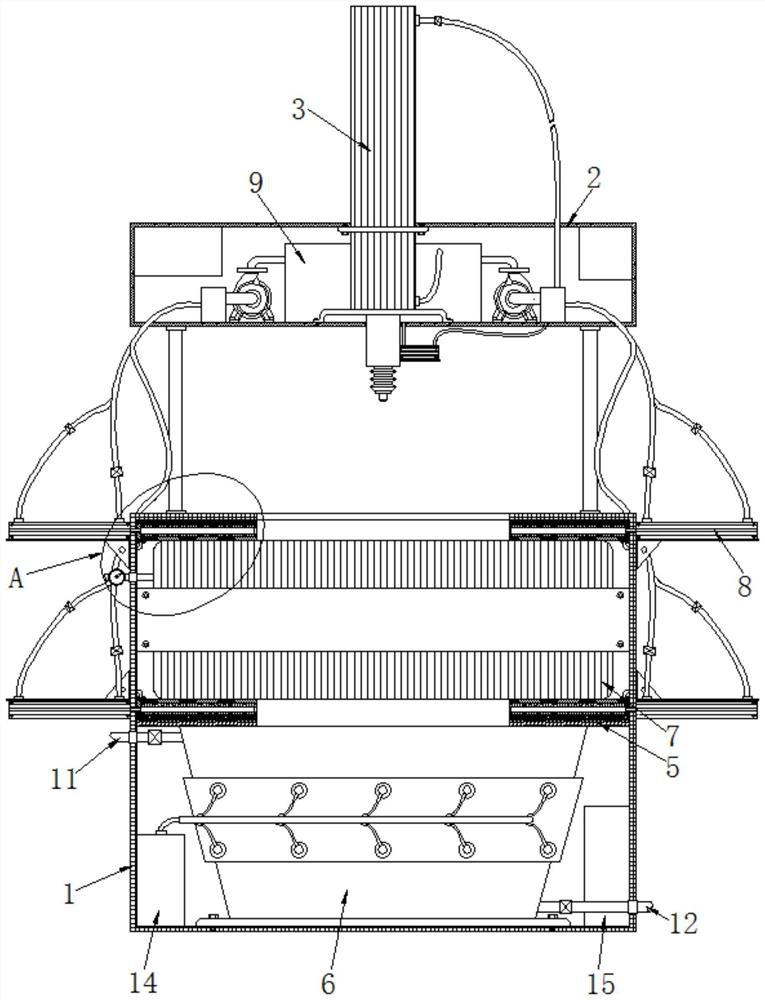

Lithium ion battery core production system

ActiveCN112151876ASolve secondary pollutionCircumstances affecting qualityFinal product manufactureElectrolyte accumulators manufactureThermodynamicsLithium-ion battery

The invention discloses a lithium ion battery core production system, which comprises a bottom box and a top box fixedly mounted at the top of the bottom box through supporting columns, wherein a hydraulic lifting mechanism is fixedly mounted at the bottom of the inner wall of the top box through a mounting frame, a charging jig is arranged at the extending end of the hydraulic lifting mechanism,a partition plate is fixedly connected between the two sides of the inner wall of the bottom box, and an immersion cylinder is fixedly installed at the bottom of the inner wall of the bottom box through a connecting plate. The invention relates to the technical field of lithium ion battery productcion. According to the lithium ion battery core production system, the battery core can be completelyprevented from being completely not in contact with the outside before being pressurized and formed, and the three procedures of baking, electrolytic solution filling and pressurizing and forming arewell integrated into one piece of sealing equipment to be completed, so that the problem of secondary pollution caused by contact between the battery core and the outside in the processing process iswell solved, subsequent processing procedures do not need to be carried out through multiple times of transfer, and the production process is simple.

Owner:宿州晟雄新能源科技有限公司

Guiding and positioning device for engineering plastic pipe production

The invention relates to the technical field of plastic pipe production guiding and positioning, in particular to a guiding and positioning device for engineering plastic pipe production. A guiding structure is installed on a base, a bearing structure is arranged at one side of the base, a fixing structure is arranged in the base, and a rotating structure is installed at the bottom end of the base; and a lifting structure is installed at the bottom end of the rotating structure, a positioning structure is installed at the top end of the base, and a limiting structure is arranged on the positioning structure. Through the arrangement of the guiding structure, an engineering plastic pipe to enter a cooling box can be accurately guided and positioned, so that the situation that because the engineering plastic pipe collides and extrudes with a feeding port of the cooling box when entering the cooling box, the quality of the pipe is affected is prevented.

Owner:徐州祥瑞工程机械科技有限公司

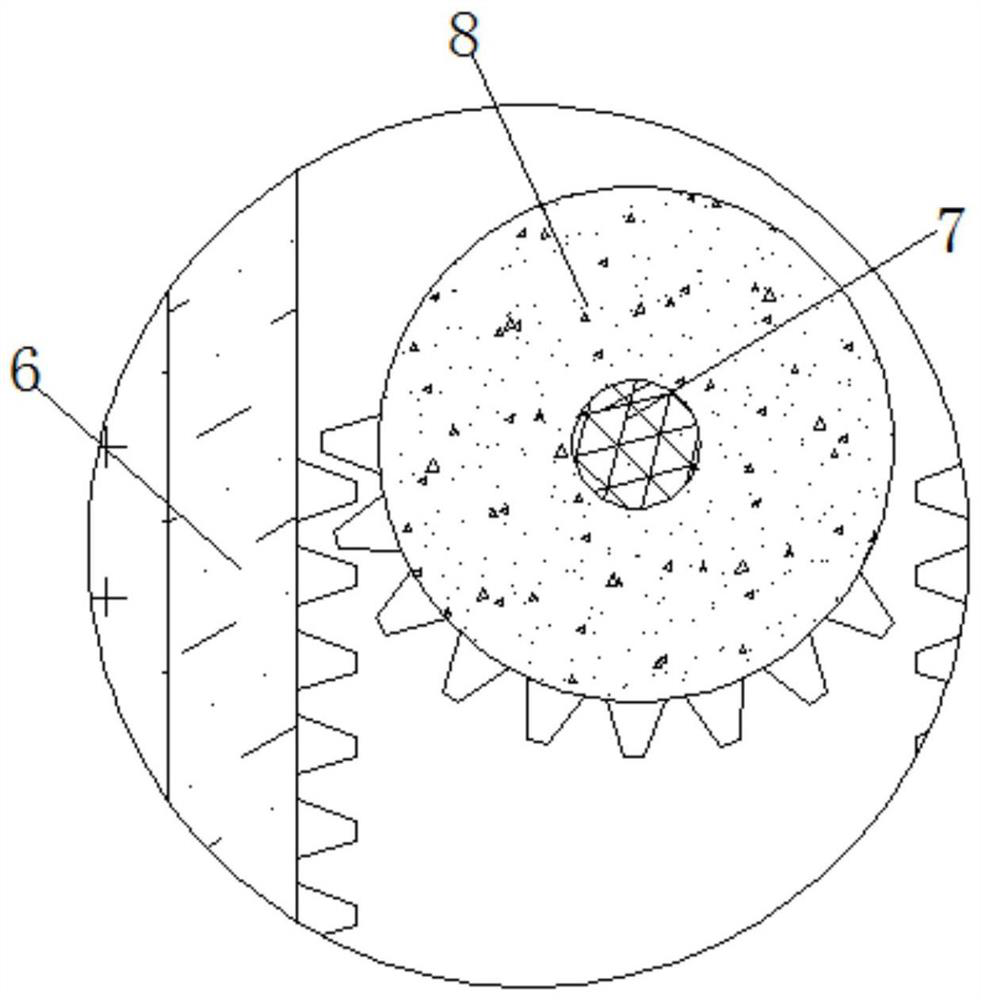

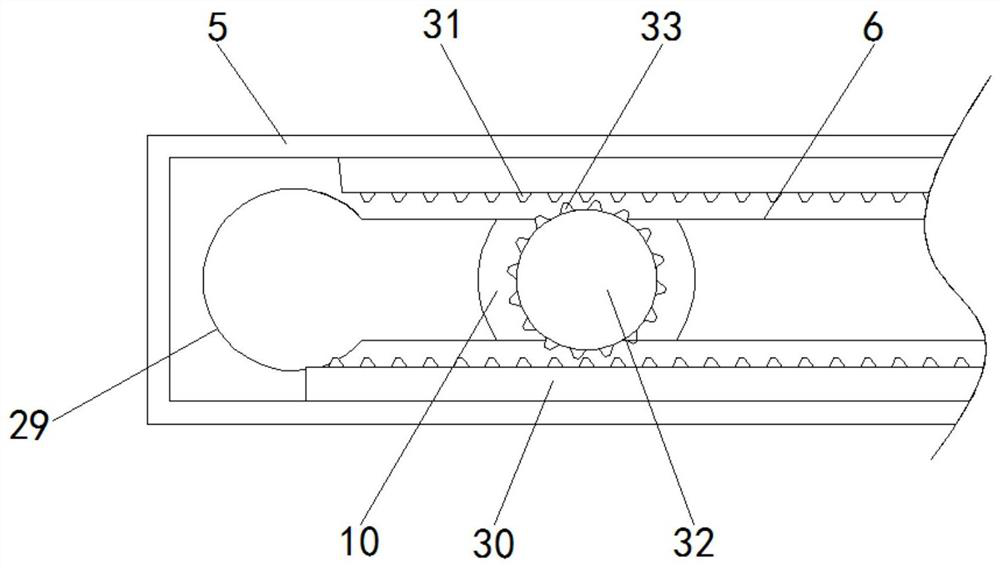

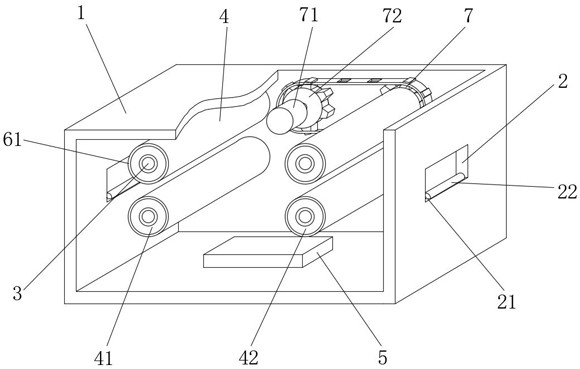

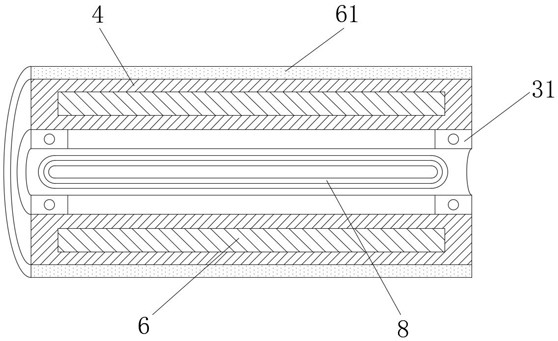

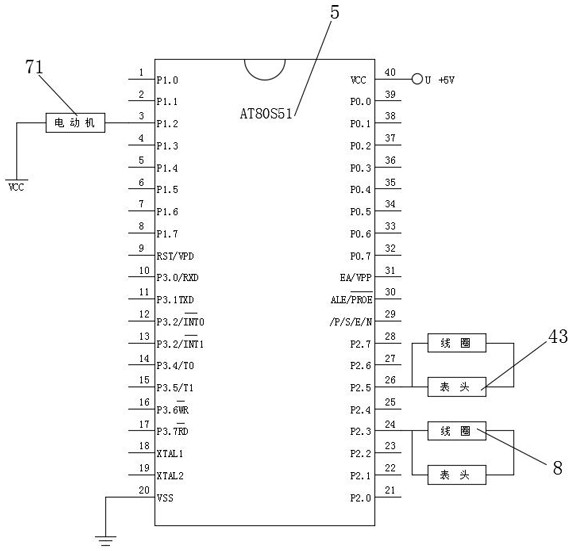

Yarn guiding device for spinning machine

ActiveCN110846750BAvoid blocking situationsAvoid compromising qualityTextiles and paperYarnGear wheel

The invention discloses a yarn guide device of a spinning machine. The yarn guide device comprises a fixing box used for mounting a yarn guide unit; two sides, far away from each other, of the fixingbox are provided with material holes respectively, and the two sides, far away from the material holes, of the fixing box are respectively fitted with freely rotatable rollers through rotating shafts;bearings are fixed on the outer walls of the two ends of each rotating shaft; coils are adhered to the inner walls of the rollers, close to the bottom of the fixing box, of an extraction set and a speed change set; a meter head is connected between two ends of each wire far away from the coils; an output end of every meter head is connected with a single chip microcomputer; a magnet is fixed inside each roller; a gear is fixed at one end, far away from the inner wall of the fixing box, of the roller, close to the top of the fixing box, of the speed change set; a power wheel is fixed on a power output shaft of a motor; the single chip microcomputer is connected with the motor through a wire; a movement groove is formed in the bottom of each material hole; and a roller shaft is mounted in each movement groove. By using the above devices together, it is possible to keep a yarn drawing speed consistent to a yarn feeding speed, and to avoid the influence on yarn stranding quality and prevent the yarn guide device from being blocked.

Owner:安徽双盈纺织有限公司

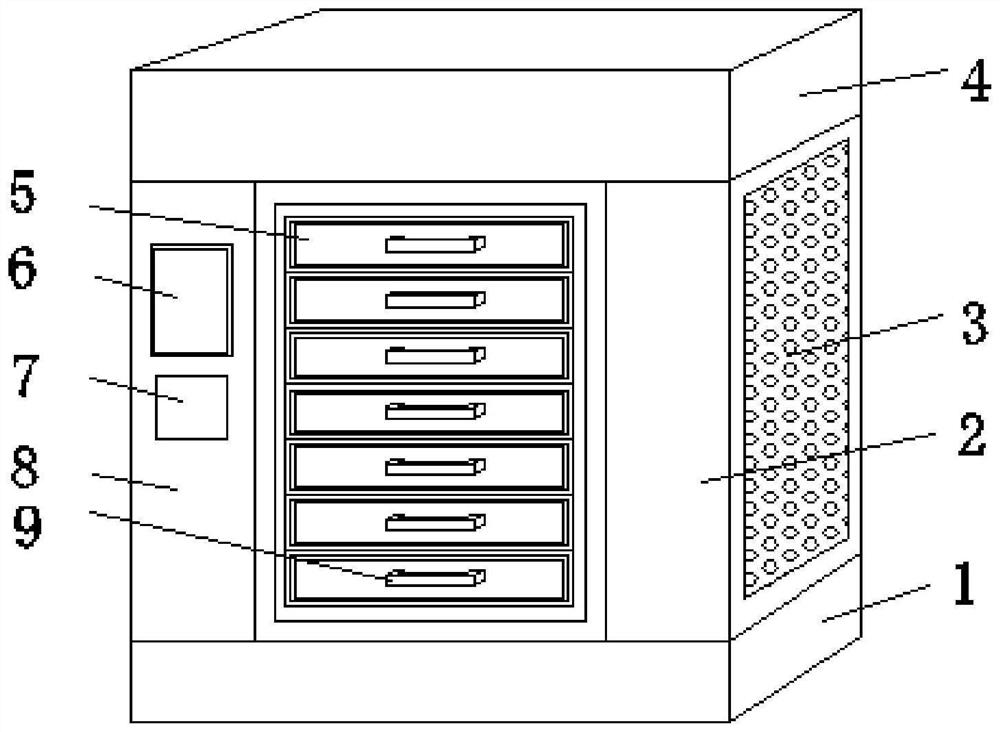

Circuit board test system

PendingCN114460100ASpeed blockAvoid the situationOptically investigating flaws/contaminationSortingMechanical engineeringElectrical and Electronics engineering

The invention discloses a circuit board test system which comprises a test cabinet, a right case is arranged on one side of the upper end of the test cabinet, a heat dissipation plate is arranged on one side of the right case, a detection case is arranged on one side of the right case, a left case is arranged on the side, away from the right case, of the detection case, a display screen is arranged on one side of the left case, and an operation panel is arranged at the lower end of the display screen. The same side of the detection case and the display screen is provided with a test drawer, the outer side of the test drawer is provided with a handle, the upper end of the test drawer is provided with a top drawer, the outer side of the test drawer is provided with a color-changing lamp strip, the color of the color-changing lamp strip can be changed into red and green, the upper end of the detection case is provided with a top case, and the top case is arranged at the upper end of the test cabinet. According to the circuit board testing system, the tester and the control machine are arranged, so that the circuit board testing system is quick in detection, low in detection missing rate and small in occupied space when the circuit board testing system is used.

Owner:湖南红鑫通信技术有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com