Circuit board test system

A technology for testing systems and circuit boards, applied in the direction of optical testing flaws/defects, measuring devices, instruments, etc., can solve the problems of large space occupation, high missed detection rate, slow detection, etc., achieve high automation efficiency and facilitate rapid detection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

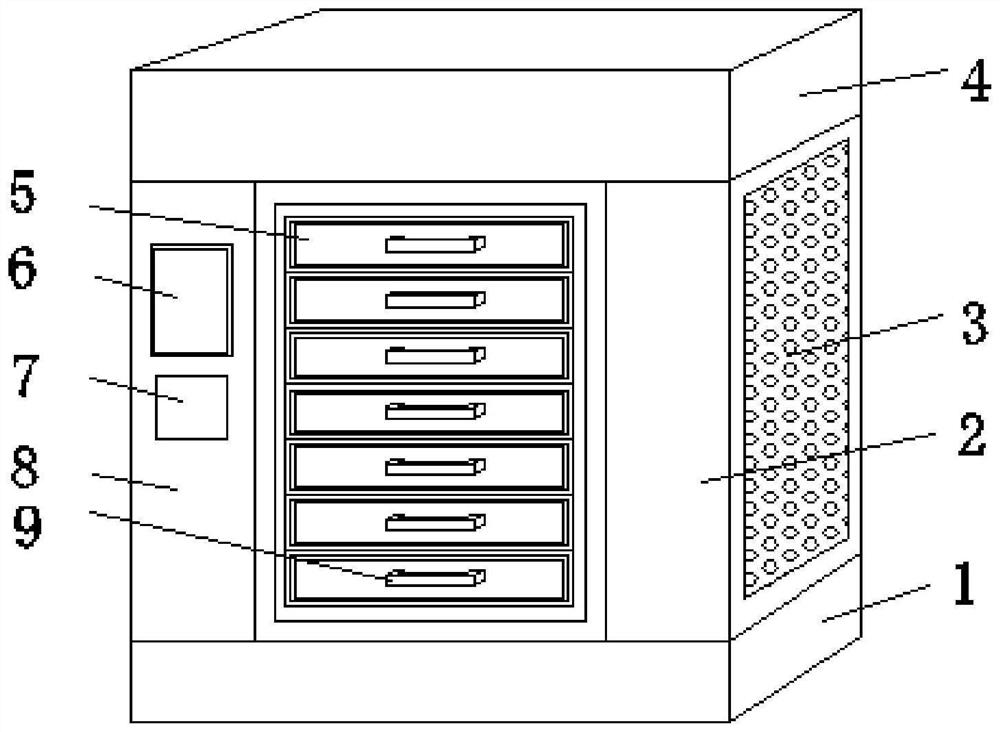

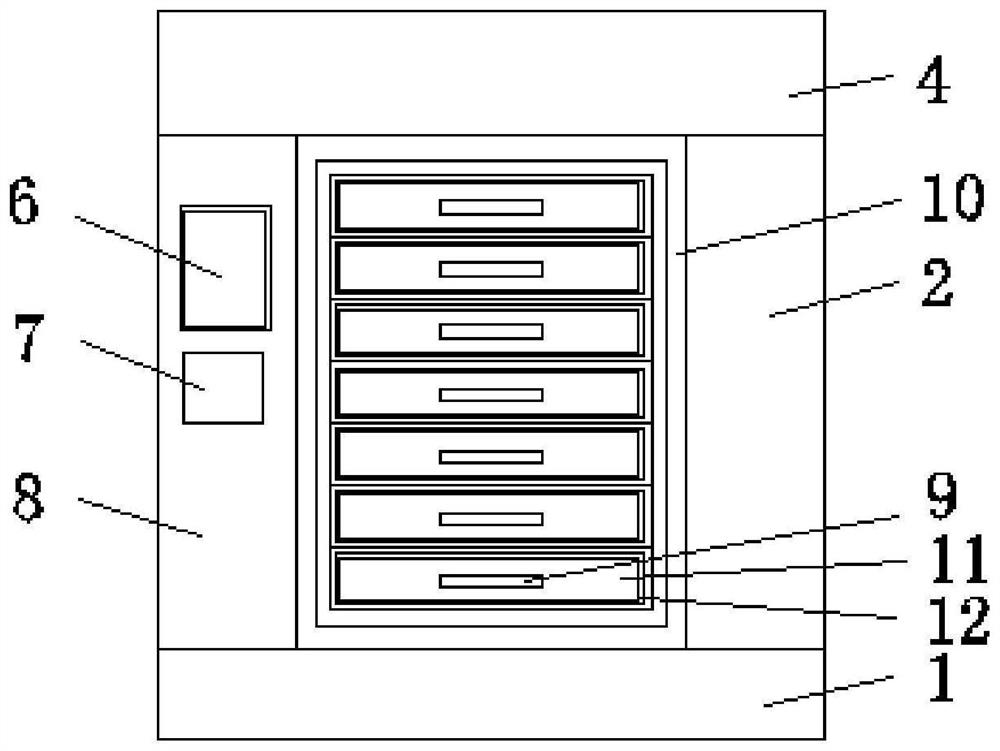

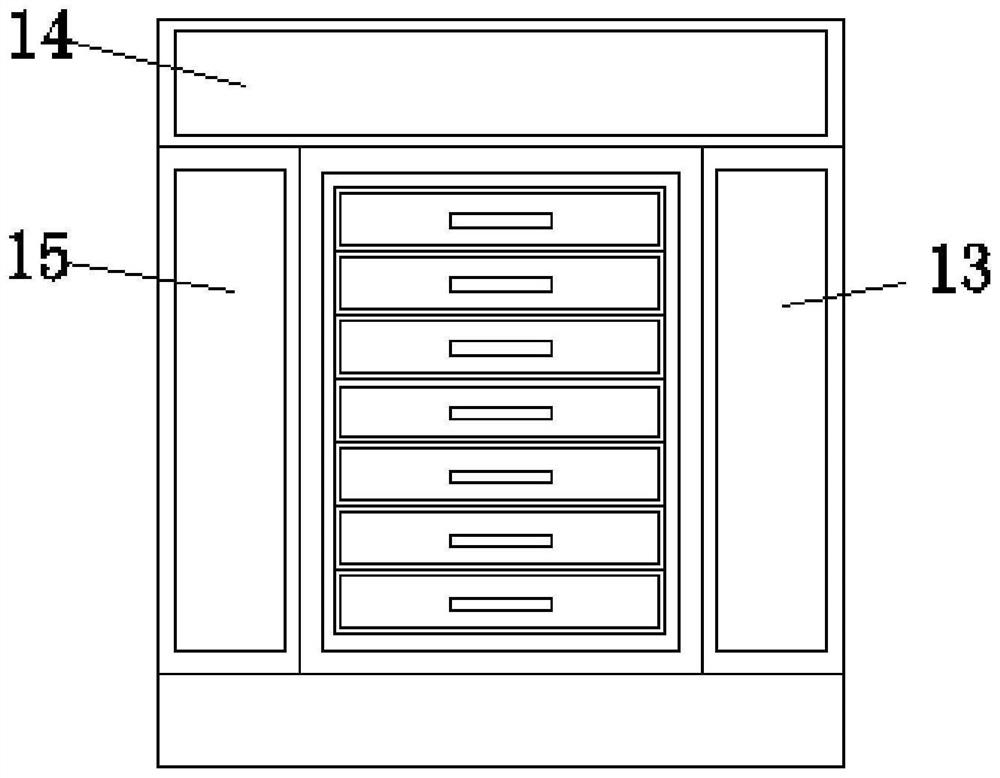

[0032] see Figure 1-7 , in this embodiment: a circuit board testing system, including a test cabinet 1, the upper side of the test cabinet 1 is provided with a right side chassis 2, and one side of the right side chassis 2 is provided with a cooling plate 3, through which heat is conducted through the cooling plate 3, Right side cabinet 2 side is provided with detection cabinet 10, and detection cabinet 10 is provided with left side cabinet 8 far away from the side of right cabinet 2, and one side of left side cabinet 8 is provided with display screen 6, and the lower end of display screen 6 is provided with The operation panel 7 operates the test cabinet 1 through the display screen 6 and the operation panel 7. The test cabinet 10 is provided with a test drawer 11 on the same side as the display screen 6, and the outside of the test drawer 11 is provided with a handle 9. Put in the circuit board to be detected, the top drawer 5 is provided on the top of the test drawer 11, a...

Embodiment 2

[0035] see Figure 1-7, in this embodiment: a circuit board testing system, including a test cabinet 1, the upper side of the test cabinet 1 is provided with a right side chassis 2, and one side of the right side chassis 2 is provided with a cooling plate 3, through which heat is conducted through the cooling plate 3, Right side cabinet 2 side is provided with detection cabinet 10, and detection cabinet 10 is provided with left side cabinet 8 far away from the side of right cabinet 2, and one side of left side cabinet 8 is provided with display screen 6, and the lower end of display screen 6 is provided with The operation panel 7 operates the test cabinet 1 through the display screen 6 and the operation panel 7. The test cabinet 10 is provided with a test drawer 11 on the same side as the display screen 6, and the outside of the test drawer 11 is provided with a handle 9. Put in the circuit board to be detected, the top drawer 5 is provided on the top of the test drawer 11, an...

Embodiment 3

[0038] see Figure 1-7 , in this embodiment: a circuit board testing system, including a test cabinet 1, the upper side of the test cabinet 1 is provided with a right side chassis 2, and one side of the right side chassis 2 is provided with a cooling plate 3, through which heat is conducted through the cooling plate 3, Right side cabinet 2 side is provided with detection cabinet 10, and detection cabinet 10 is provided with left side cabinet 8 far away from the side of right cabinet 2, and one side of left side cabinet 8 is provided with display screen 6, and the lower end of display screen 6 is provided with The operation panel 7 operates the test cabinet 1 through the display screen 6 and the operation panel 7. The test cabinet 10 is provided with a test drawer 11 on the same side as the display screen 6, and the outside of the test drawer 11 is provided with a handle 9. Put in the circuit board to be detected, the top drawer 5 is provided on the top of the test drawer 11, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com