Epitaxial growth apparatus

A technology of epitaxial growth and pedestal, which is applied in the direction of single crystal growth, crystal growth, climate sustainability, etc., can solve the problem of low output efficiency of epitaxial layer, and achieve the effect of improving production efficiency and output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

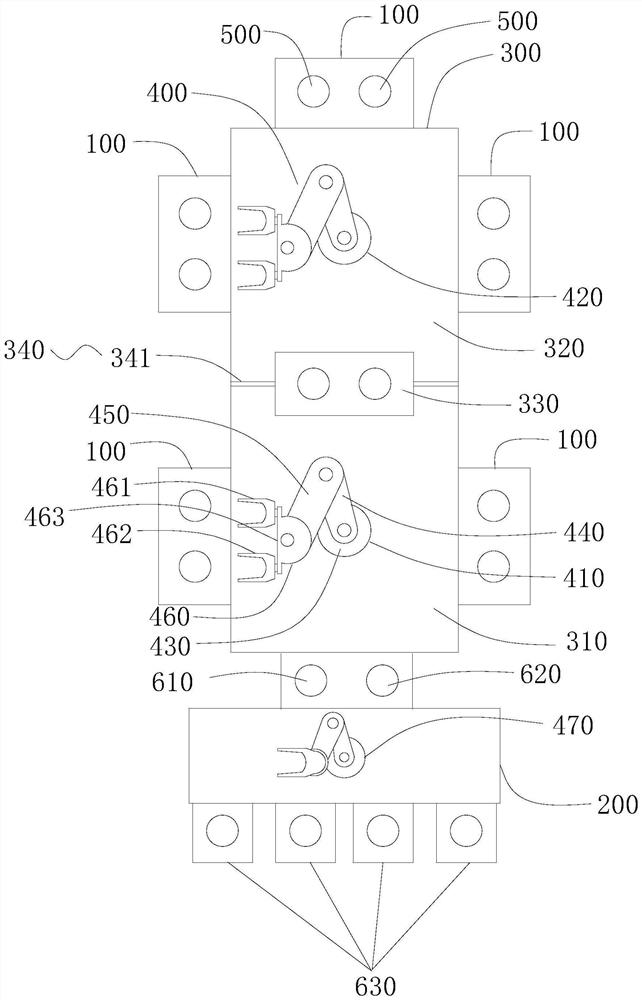

[0065] like image 3 and Figure 4 As shown, the operating table 300 includes a first operating area 310 and a second operating area 320, a plurality of epitaxial growth devices 100, a second operating area 320 and a loading and unloading table 200 are respectively disposed on different sides of the first operating area 310, and many The epitaxial growth devices 100 are disposed on different sides of the second operation region 320 , that is, other side surfaces of the second operation region 320 that are not adjacent to the first operation region 310 are provided with a plurality of epitaxial growth devices 100 . The robotic arm assembly 400 includes a first transfer arm 410 and a second transfer arm 420 . The first transfer arm 410 is disposed in the first operation area 310 , and the second transfer arm 420 is disposed in the second operation area 320 . Also, the first transfer arm 410 can move up and down in a direction perpendicular to the first operation area 310 for tr...

Embodiment 2

[0074] like Image 6 As shown, the operating table 300 is polygonal, the loading and unloading table 200 and a plurality of epitaxial growth devices 100 are distributed in different side regions of the operating table 300 , and the robotic arm assembly 400 can be transferred between the epitaxial growth device 100 and the loading and unloading table 200 Wafer 500. Specifically, in one embodiment, the operation table 300 is in an octagonal shape, the loading and unloading table 200 is disposed on one side of the operation table 300 , and five epitaxial growth devices 100 are respectively disposed on five sides away from the loading and unloading table 200 . In this way, the epitaxial deposition apparatus can simultaneously grow 10 epitaxial layers of the silicon wafers 500, which greatly improves the yield of the silicon wafers 500 of the epitaxial deposition apparatus.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com