Temperature control system suitable for industrial 3D printer

A temperature control system and 3D printer technology, applied in the direction of temperature control using electric methods, auxiliary controllers with auxiliary heating devices, etc., can solve unstable temperature control, affect the quality of printed workpieces, and fail to reach the preset temperature and other issues to achieve the effect of improving real-time and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

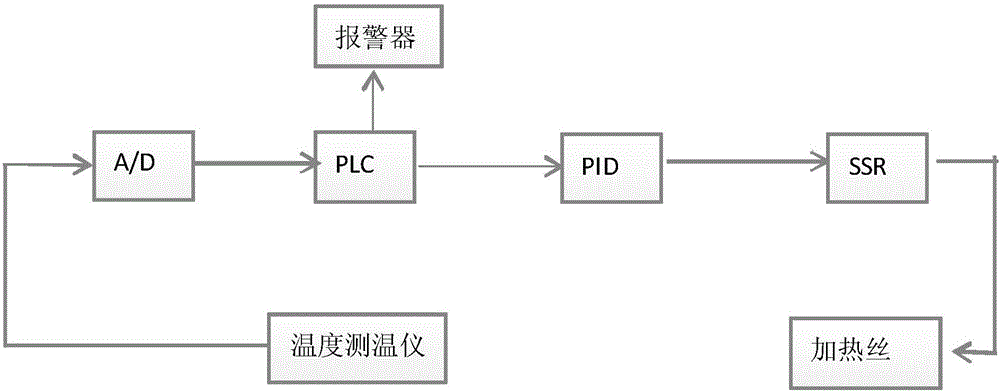

[0017] Such as figure 1 As shown, the present invention is a temperature control system suitable for industrial-grade 3D printers, which is a PID-based temperature control system, including a thermometer, an AD conversion module, a programmable logic controller PLC, a PID control module, and a solid-state relay .

[0018] The thermometer placed at the mouth of the forming chamber of the industrial 3D printer is used to obtain the real-time temperature in the forming chamber.

[0019] The thermometer is connected with the AD conversion module, and the thermometer transmits the temperature analog quantity collected to the AD conversion module.

[0020] The AD conversion module is connected with the programmable logic controller PLC, and the AD conversion module converts the analog temperature value transmitted by the thermometer into a digital value, and tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com