Air hole pre-setting device for cast sand mold

A technology of air holes and sand molds, which is applied in the field of sand mold casting, and can solve problems such as complex operation, scrapping of castings, poor exhaust effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

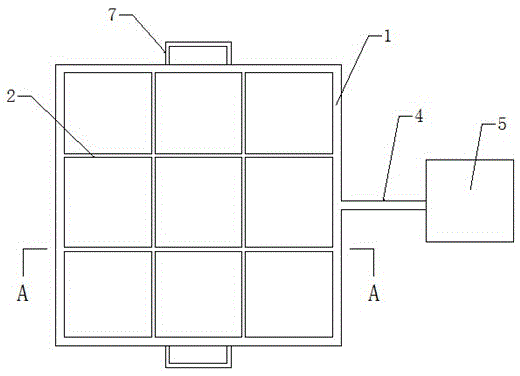

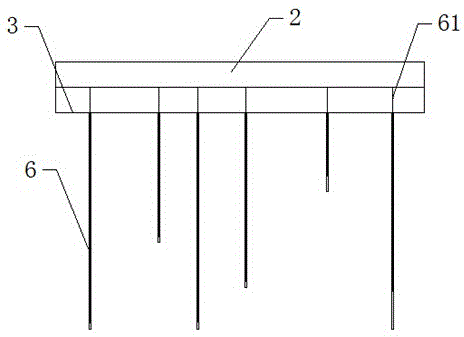

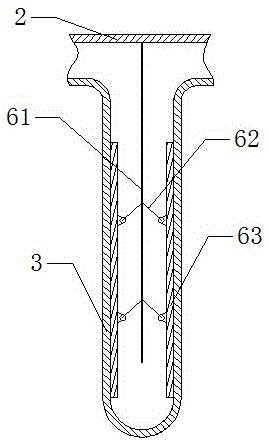

[0016] The reference numerals in the accompanying drawings of the specification include: skeleton 1 , pole 2 , airbag 3 , trachea 4 , air pump 5 , airbag post 6 , pressing rod 61 , ejector rod 62 , support plate 63 , and handle 7 .

[0017] The embodiment is basically as attached figure 1 , figure 2 Shown: the casting sand tire preset air hole device includes a frame body, an air pipe 4 connected to the frame body and an air pump 5 communicated with the air pipe 4 . The frame body includes a skeleton 1 and an airbag 3, the skeleton 1 is in the shape of a rectangular frame, and the interior of the skeleton 1 is provided with a number of struts 2 distributed in a cross shape, and the two ends of the struts 2 are welded on the skeleton 1 . The air bag 3 is fixed on the lower end of the frame 1 and the strut 2 , and the air bag 3 communicates with the trachea 4 . The low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com