Dust falling and noise reduction type leather shoe sole polishing device

A noise reduction type, leather shoe technology, applied in the direction of grinding drive device, grinding/polishing safety device, grinding machine, etc., can solve the problems of increased workload, noise, noise pollution, etc., to prolong service life, reduce noise, and facilitate The effect of cleanup and collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

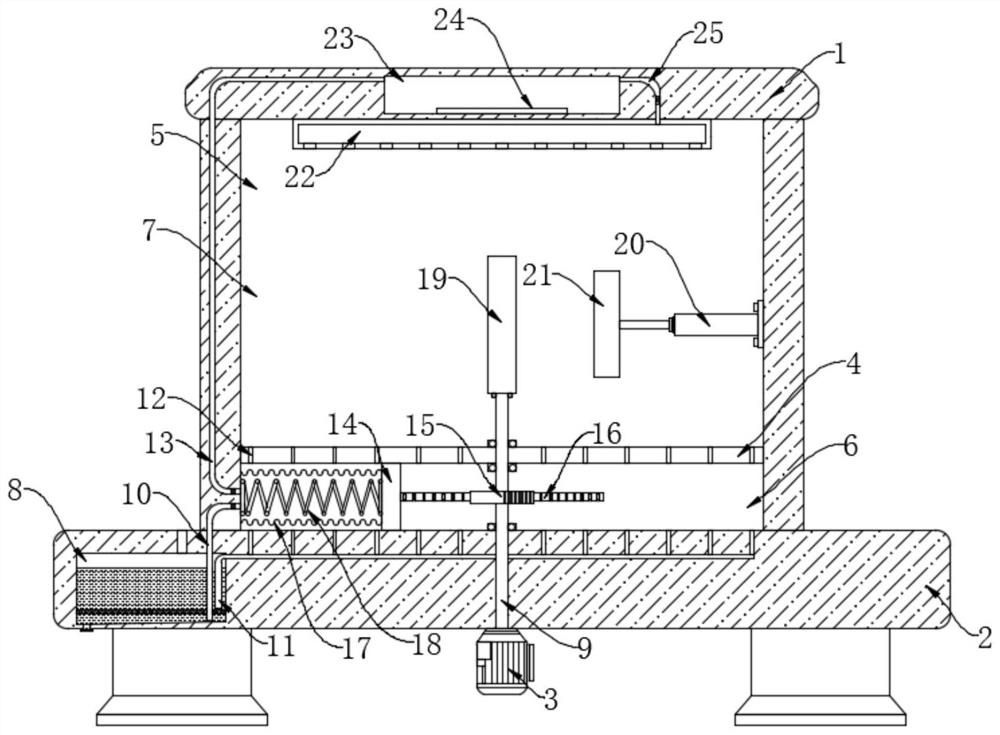

[0020] refer to figure 1 , a dust-reducing and noise-reducing type leather shoe sole grinding device, comprising a cabinet body 1, the lower end of the cabinet body 1 is fixedly connected with a base 2, and the cabinet body 1 is sequentially provided with an atomization chamber 23 and a square chamber 7 from the inside to the bottom. A horizontal plate 4 is horizontally arranged in the chamber 7, and the horizontal plate 4 divides the square chamber 7 into a grinding chamber 5 and a reciprocating chamber 6. The front side of the grinding chamber 5 is provided with a sliding door, and the grinding chamber 5 is located above the reciprocating chamber 6. A liquid storage chamber 8 is provided inside, a rotary door is provided on the front side of the liquid storage chamber 8, a water outlet is provided at the inner bottom of the liquid storage chamber 8, and a stopper is provided at the end of the water outlet away from the liquid storage chamber 8;

[0021] Grinding mechanism, t...

Embodiment 2

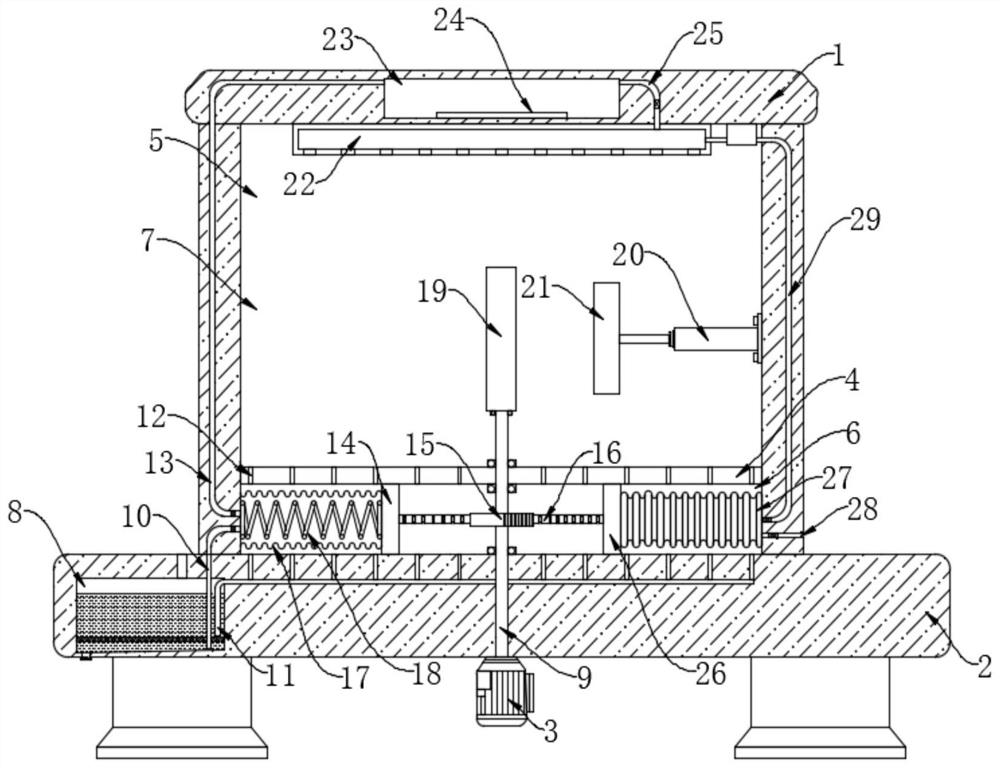

[0029] refer to figure 2 The difference between this embodiment and Embodiment 1 is that the end of the rack 16 away from the sliding block 14 is fixedly connected with a moving block 26, and the moving block 26 is slidably connected with the inner top and inner bottom of the reciprocating cavity 6, and the moving block 26 An end far away from the rack 16 is fixedly connected with a flexible air bag 27, and an end of the flexible air bag 27 away from the moving block 26 is fixedly connected with the right side inner wall of the reciprocating chamber 6, and the right end of the flexible air bag 27 communicates with the outside world through the intake pipe 28. The right end communicates with the right side inner wall of the hollow plate 22 through the air outlet pipe 29, and the air inlet pipe 28, the air outlet pipe 29 and the connecting pipe 25 are all provided with a one-way valve. The gas in 27 enters the hollow plate 22 in one direction through the air outlet pipe 29, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com