Paper making felt needle machine unrolling device

A technology of unwinding device and papermaking felt, which is applied to needle punching machine, textile and papermaking, winding strip, etc., can solve problems such as poor quality of felt, and achieve the effects of improving quality, stable structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

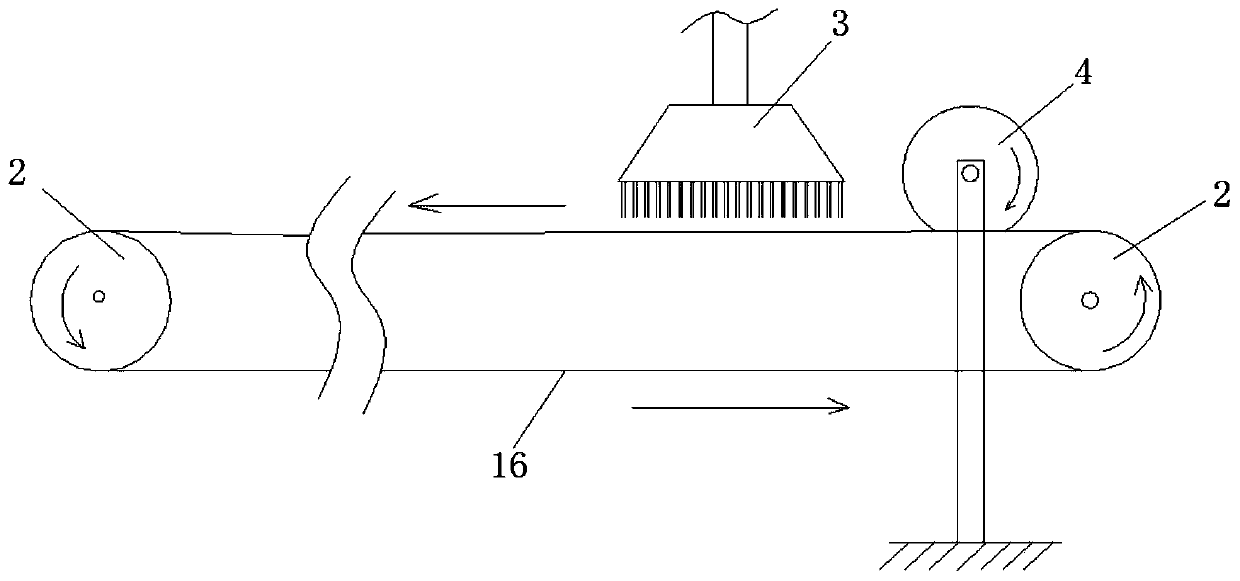

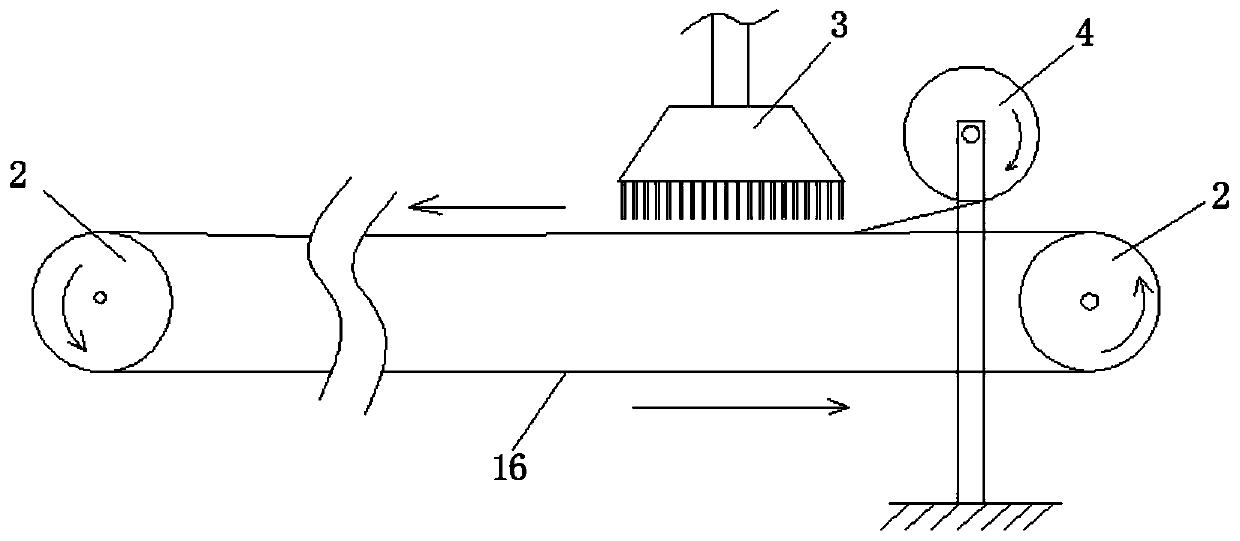

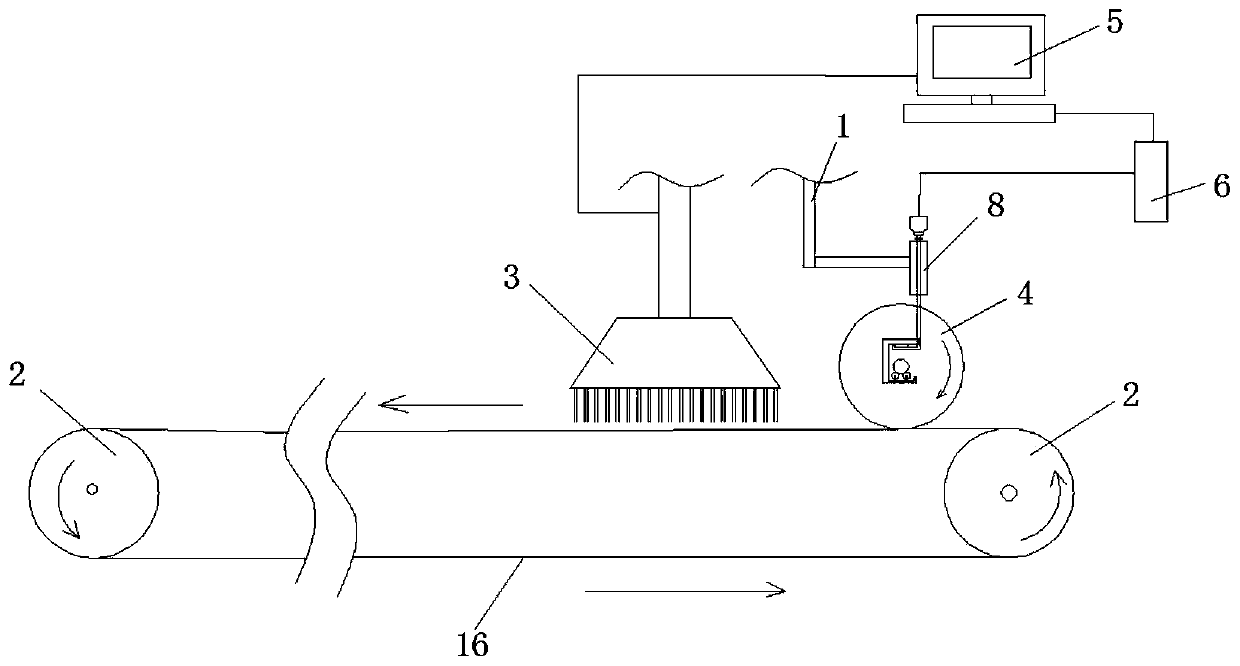

[0037] Such as image 3 and Figure 4 Shown:

[0038] An unwinding device for a felt needle punching machine for papermaking, comprising a frame 1, a fabric guide roller 2, an acupuncture mechanism 3, a computer 5, a PLC controller 6, a first elevator 8, a first pressure sensor 7 and a front unwinding The first wool roll 4; wherein,

[0039] The cloth guide roller 2 and the acupuncture mechanism 3 are all arranged on the frame 1, the base web 16 is wound on the cloth guide roller 2, and the base web 16 is driven to rotate by the cloth guide roller 2, and the acupuncture mechanism 3 can lay the cloth on the base web. The fluff on the hair roll on the net 16 is stuck in the base net 16, so that the base net 16 is combined with the hair roll more closely;

[0040] The acupuncture mechanism 3 is connected with a computer 5, and the computer 5 is used to calculate the theoretical weight value of the remaining hair roll on the first hair roll roller 4;

[0041] The first pressur...

Embodiment 2

[0058] Such as Figure 5 and Figure 6 Shown:

[0059] As a further optimization of the above embodiment, the unwinding device of the papermaking felt needle loom also includes a second lap roll 12 and a second elevator 13; the second lap roll 12 is located inside the base web 16, and it is mainly used for the base web The unwinding of the back side of 16 enables the unwinding device of the papermaking felt needleloom machine to simultaneously lay the front and back sides of the base web 16, making the use of the papermaking felt needleloom unwinding device more convenient.

[0060] Optimally, the lifting end of the second elevator 13 is provided with a second support frame 15, and the above-mentioned second bobbin roll 12 is rotatably arranged on the second support frame 15, and the lifting end of the second elevator 13 and the second support frame 15 A second pressure sensor 14 is arranged between them, and the second pressure sensor 14 can be used to detect the actual wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com