Carving device capable of timely polishing after carving and used for jujube wood artware processing

A kind of wood handicraft and timely technology, applied in the direction of grinding/polishing safety device, engraving, processing model, etc., can solve the problems of multi-burr burr, easy accidental injury to staff, inability to polish jujube wood handicrafts, etc., and achieves easy use and operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

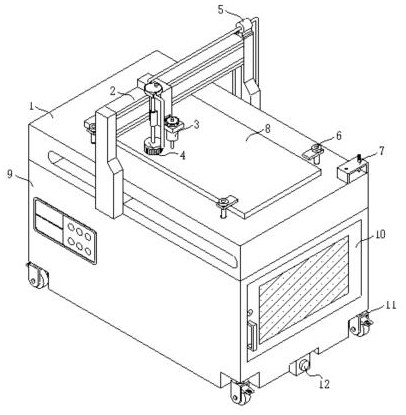

[0039] Such as figure 1 As shown, this embodiment proposes a kind of engraving device for jujube handicraft processing that can be polished in time after engraving, including a workbench 1, a three-axis drive module 2 is arranged on the top of the workbench 1, and a three-axis drive module 2 is provided on the three-axis drive module 2. The engraving mechanism 3 and the cleaning mechanism 4 and the dust suction mechanism 5 located on the side of the carving mechanism 3 can absorb the dust generated during the processing by setting the dust suction mechanism 5 to reduce the adverse effects caused by the dust diffusion. The top of the workbench 1 A backing plate 8 and four fixing mechanisms 6 respectively positioned at both sides of the backing plate 8 are fixedly installed. The top of the backing plate 8 is rough, which can improve the stability of jujube wood being placed on it. One corner is also provided with a knife storage mechanism 7, and the bottom of the workbench 1 is ...

Embodiment 2

[0041] The scheme in embodiment 1 is further introduced below in conjunction with specific working methods, see the following description for details:

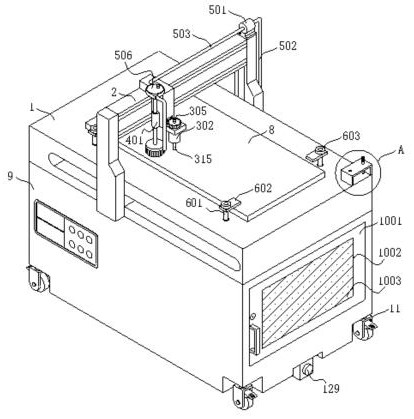

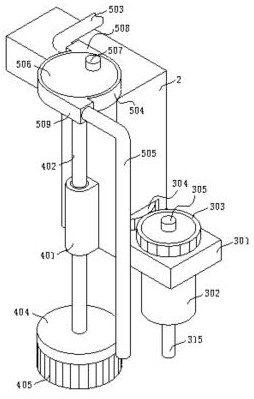

[0042] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, as a preferred embodiment, on the basis of the above method, further, the engraving mechanism 3 includes a support plate 301 installed on the three-axis drive module 2, the middle part of the support plate 301 is connected with a rotating shaft 302 through a bearing, and the rotating shaft The outer surface of 302 is fixedly sleeved with a transmission gear 303 located above the support plate 301. One side of the transmission gear 303 is provided with a drive assembly 304 located in the three-axis drive module 2 for driving the transmission gear 303 to rotate. The drive assembly 304 is formed by Composed of a motor and a driving gear, the motor is installed in the three-axis drive module 2, the driving gear is installed on the output shaft of the motor a...

Embodiment 3

[0053] The schemes in Embodiment 1 and Embodiment 2 are further introduced below in conjunction with specific working methods, see the following description for details:

[0054] Specifically, when the engraving device for the processing of jujube wood handicrafts that can be polished in time after carving is at work / in use: first place the jujube board on the top of the backing plate 8, then hold the fixed plate 602 and turn the hand wheel 603, and then turn the hand wheel 603 by hand The wheel 603 drives the threaded rod 601 to rotate so that the fixed plate 602 descends and contacts the jujube board, that is, the jujube board is clamped and fixed;

[0055] Start the three-axis drive module 2, exhaust fan 501 and drive assembly 304, drive the transmission gear 303 to rotate through the drive assembly 304, drive the rotating shaft 302 and the carving knife 315 to rotate through the transmission gear 303, and engrave the jujube board through the carving knife 315, engraving Du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com