Petal type big flame cover and combustor provided with same

A technology of a large fire cover and a burner, which is applied to burners, gas fuel burners, combustion methods, etc., can solve the problems of a large amount of flue gas, waste of energy, energy waste, etc., and achieve full combustion of gas, improve safety, and improve thermal efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

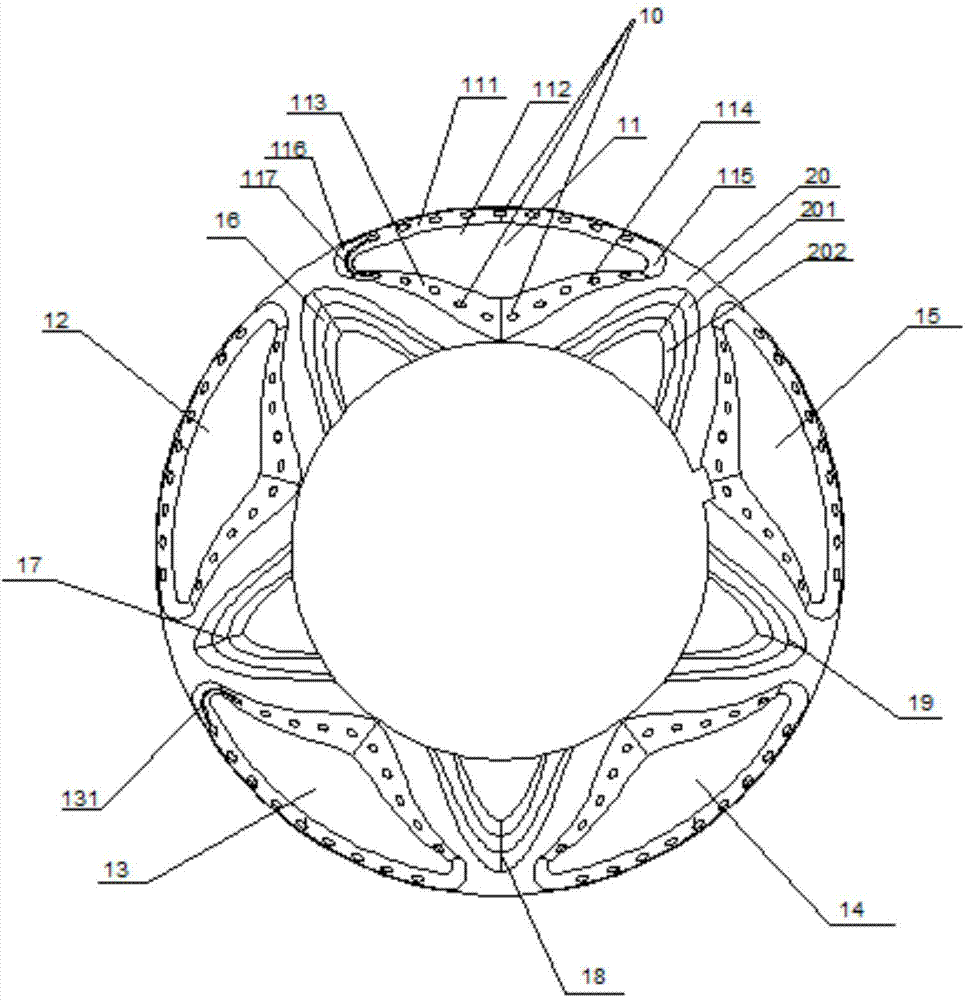

[0037] Such as figure 1 Shown, present embodiment proposes a kind of petal formula big fire cover. A plurality of fire holes 10 are disposed on the first side 111 , the second side 113 and the third side 114 . In this embodiment, the width of the fire cover is 25mm.

[0038] Such as figure 1 As shown, the upper surface of the fire cover 1 is provided with five bosses at intervals, which are respectively the first boss 11, the second boss 12, the third boss 13, the fourth boss 14 and the fifth boss 15, two A passage for supplementing secondary air is provided between adjacent bosses, that is, there is a gap between two adjacent bosses. Each channel for supplying secondary air is formed with concave platforms, which are respectively the first concave platform 16, the second concave platform 17, the third concave platform 18, the fourth concave platform 19 and the fifth concave platform 20. The platform and the concave platform are arranged at intervals in the manner of one c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com