Two-stage stroke core-pulling structure in refrigerator foam mold

A foaming mold and two-stage stroke technology, which is applied in the field of box foaming molds, can solve the problems of not being able to complete at the same time, design difficulties, and limited space in the inner cavity of box foaming molds, so as to improve work efficiency and reduce design difficulty , The effect of simple and convenient mold assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

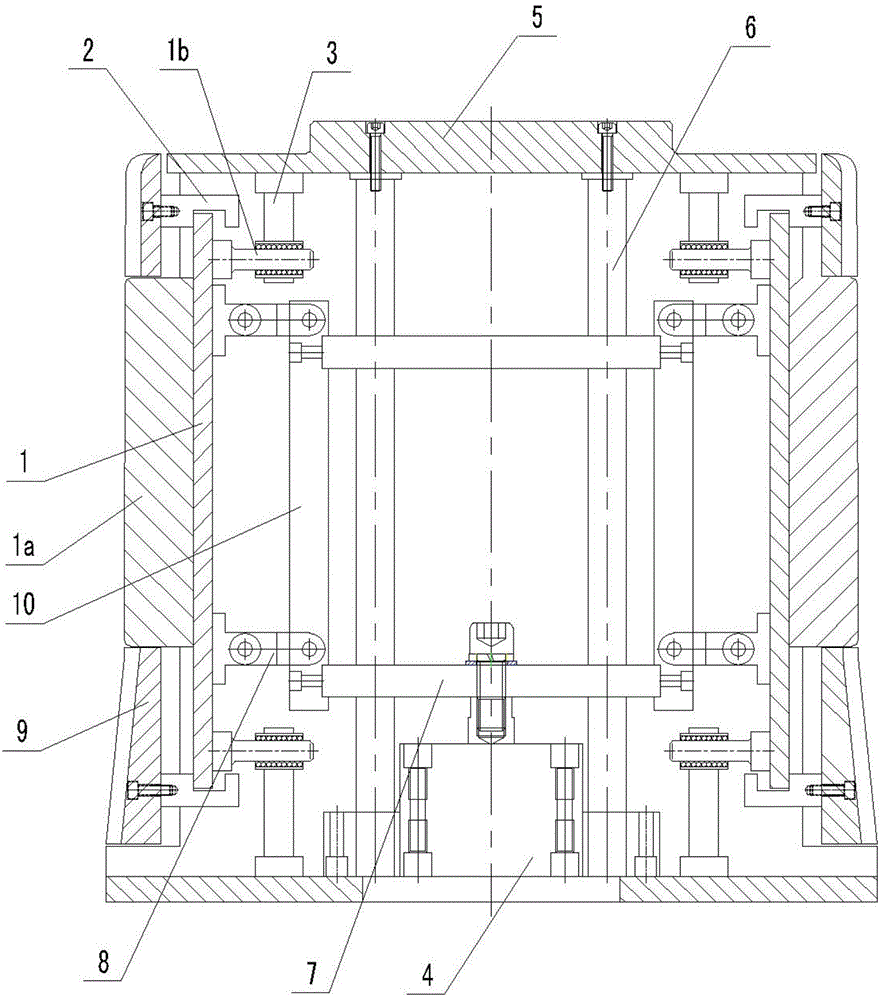

[0016] see figure 1 , the core-pulling structure of the secondary stroke in the foaming mold of the refrigerator in this embodiment is:

[0017] A core-pulling block 1a is provided in the middle of the rising plate 9 in the form of a sliding sleeve, which can slide relative to the rising plate 9 along the core-pulling direction, and the core-pulling block is fixed on the core-pulling block fixing seat 1 .

[0018] A pair of parallel main guide rods 6 is provided with a push plate 7 driven by the cylinder 4 and can slide along the main guide rods 6 , the end of the push plate 7 is hinged to the core pulling block fixing seat 1 through a connecting rod 8 .

[0019] The core-pulling block guide rod 1b is arranged on the core-pulling block fixing seat 1 according to the core-pulling direction, and the guide sleeve 3 cooperating with the core-pulling block guide rod 1b is fixedly arranged on the mold frame 5 .

[0020] The limit block 2 is set on the rising plate 9, the two ends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com