Automatic laminator

A film laminating machine and automatic technology, which is applied in the direction of automatic packaging control, conveyor objects, flexible coverings, etc., can solve problems such as inability to align the film with the product, poor film quality, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

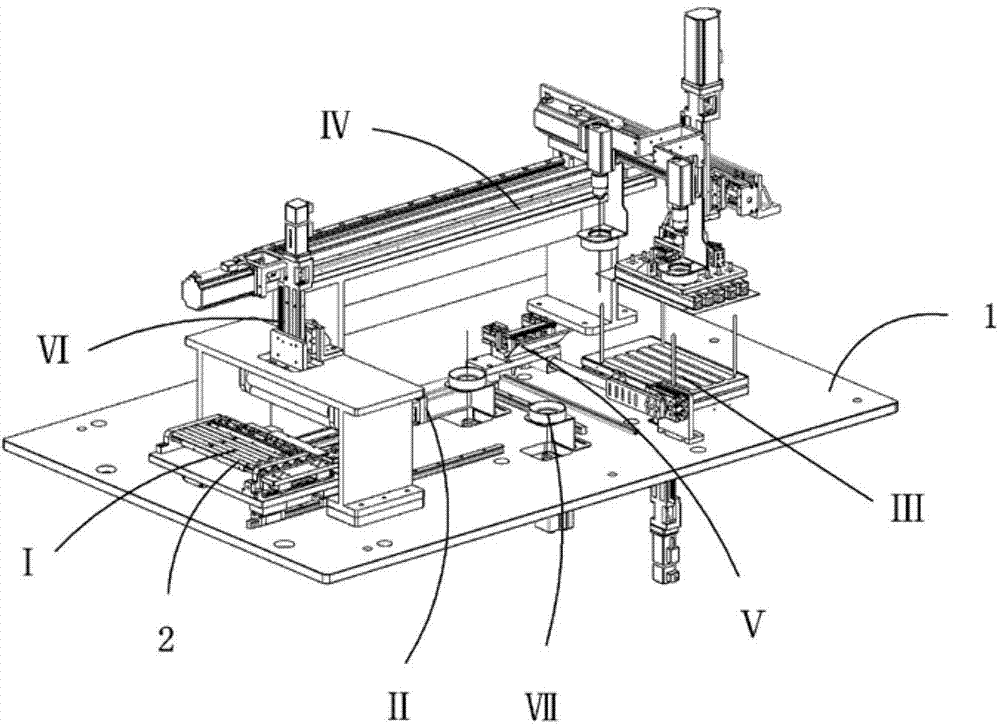

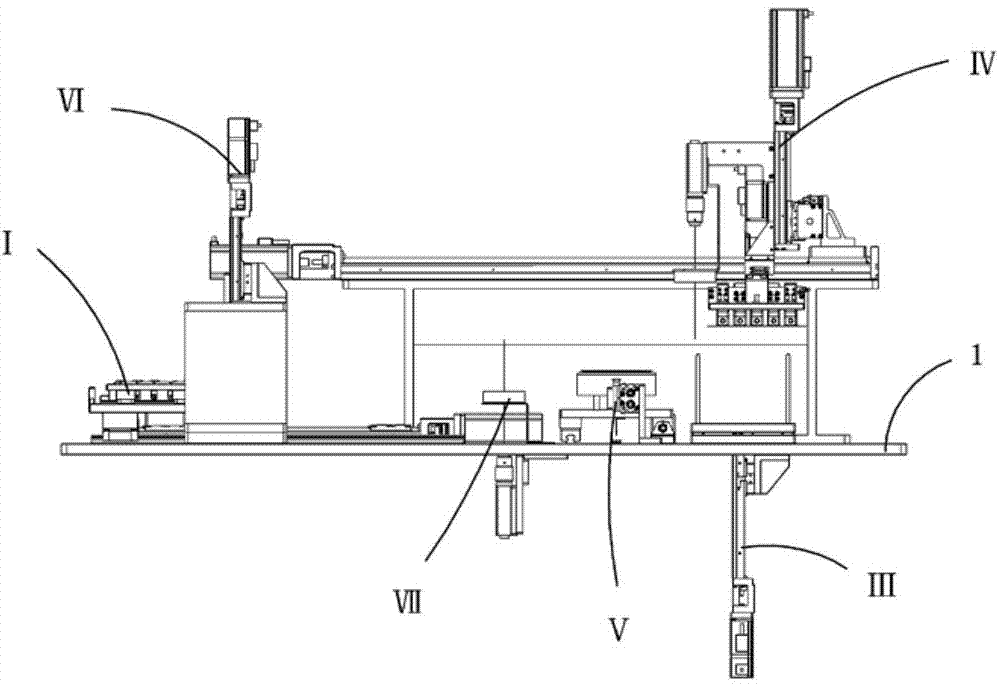

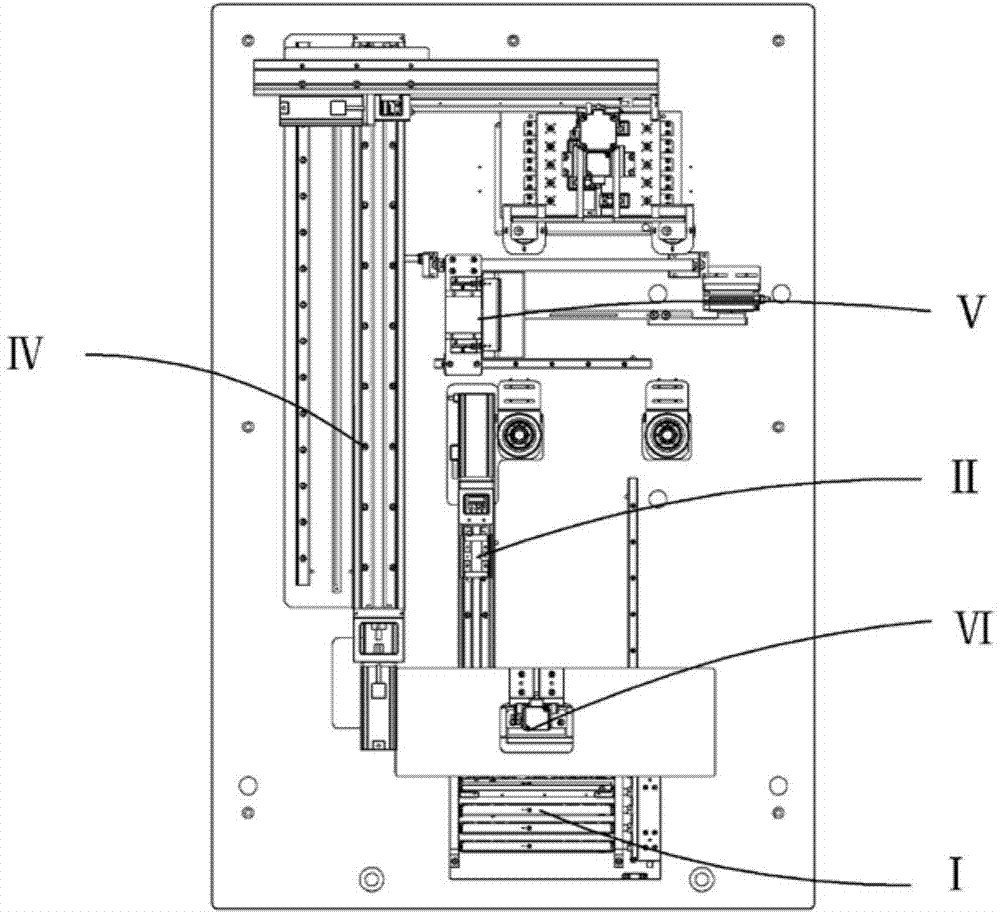

[0036] Examples, see attached Figure 1-17 , an automatic film laminating machine, which includes a bottom plate 1, a carrier mechanism I, a carrier transport mechanism II, a feeding mechanism III, a material suction mechanism IV, a film peeling mechanism V, a film pressing mechanism VI, a product 2, a material film 3, Protective film 4 and CCD mechanism VII, the carrier transport mechanism is installed on the bottom plate; the carrier mechanism is installed on the carrier transport mechanism; a protective film is attached under the material film, and the material film is placed on the feeding mechanism ; The film-removing mechanism, the film-pressing mechanism and the CCD mechanism are installed on the base plate respectively, and the film-pressing mechanism is located above the carrier transport mechanism; multiple products are installed on the carrier mechanism; planes in the same horizontal plane.

[0037] See attached Figure 4 and Figure 5 , the carrier mechanism inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com