Object absorbing device

An adsorption device and object technology, which is applied in the direction of conveyor objects, transportation and packaging, furnaces, etc., can solve the problems of unstable adsorption force, high energy consumption, and high surface flatness requirements, and achieve stable adsorption effect, large adsorption force, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

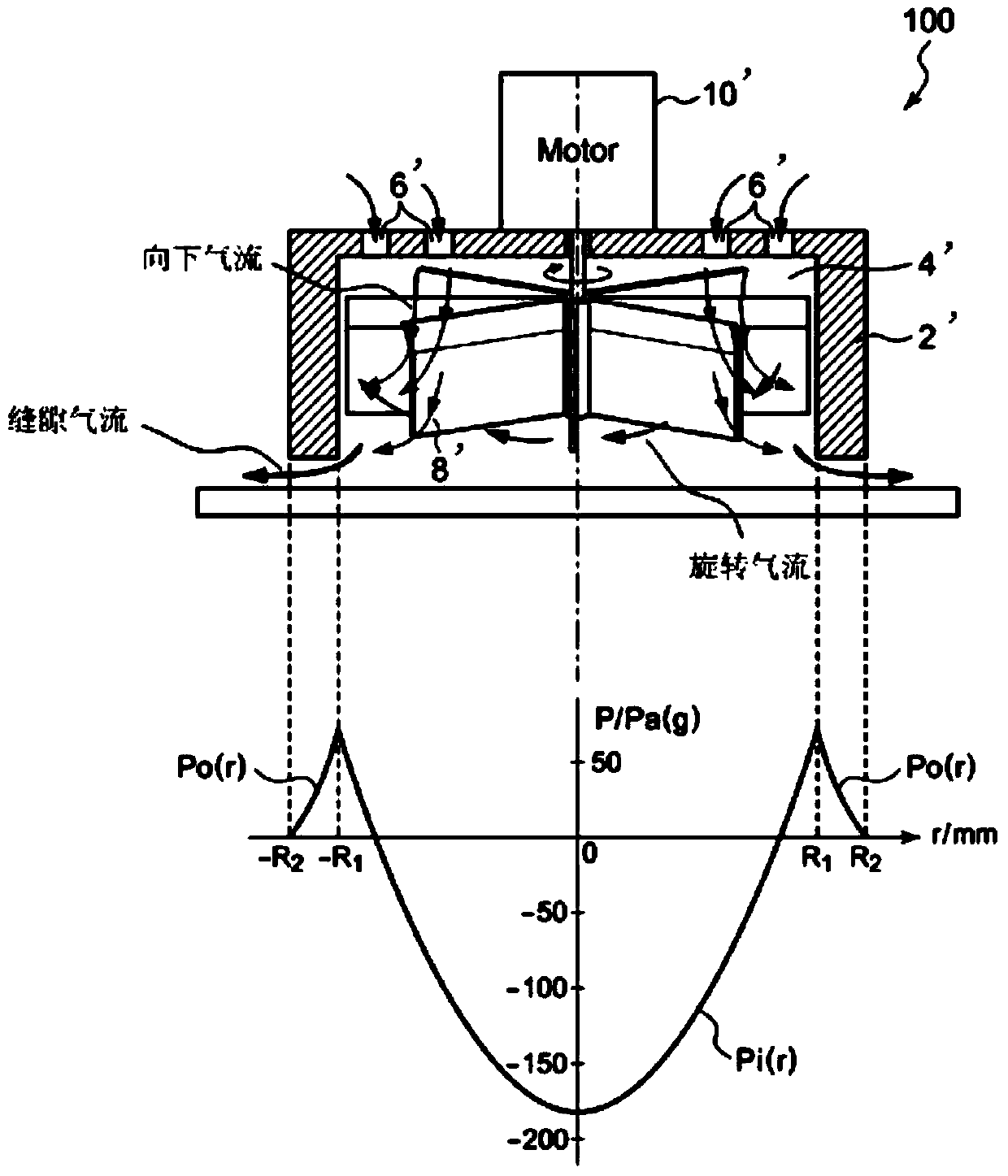

[0034] Referring to the attached picture:

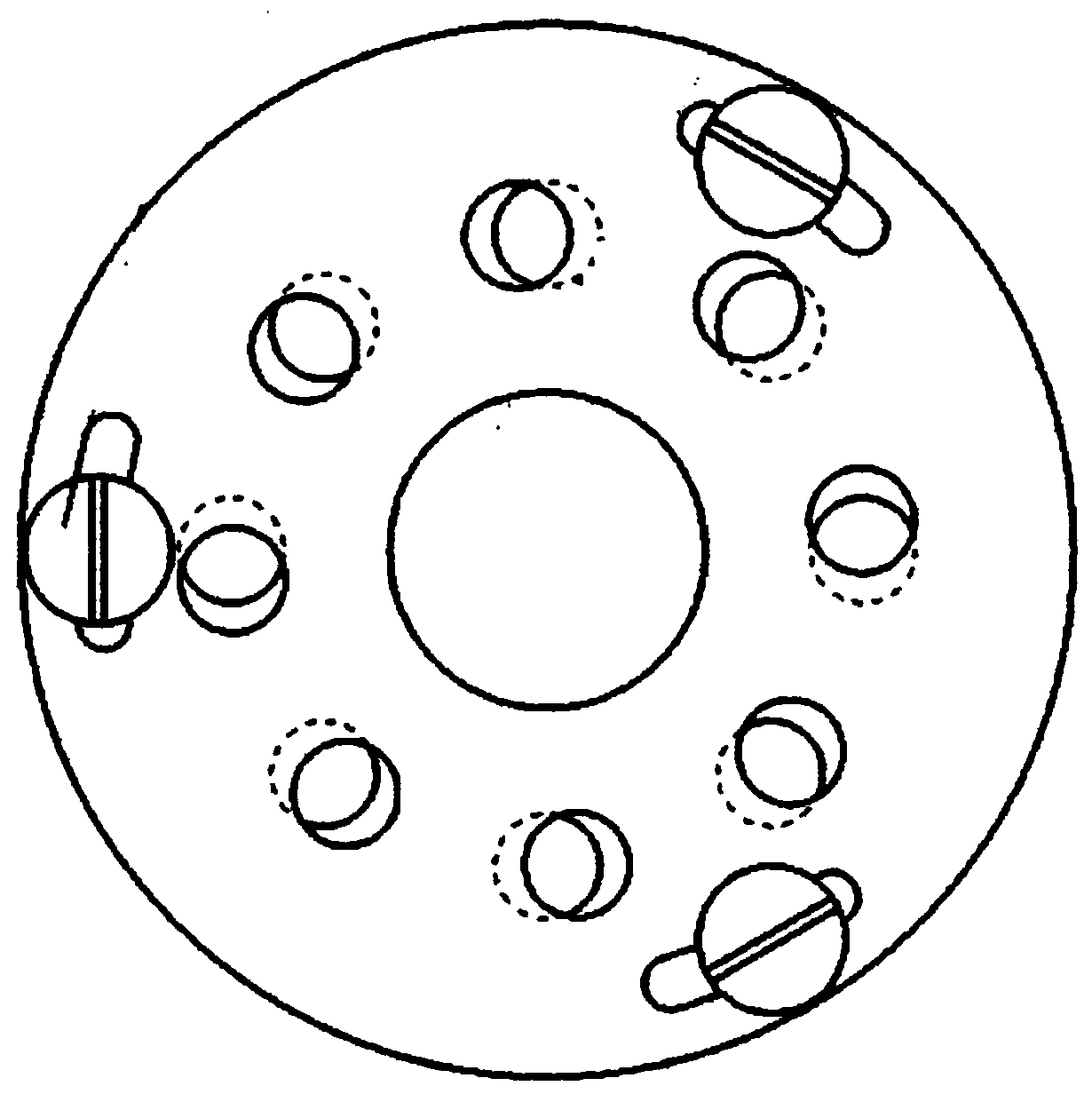

[0035] The object adsorption device includes a shell 1 with a circular cross section, and a cavity 11 with a circular cross section inside the shell. The cavity 11 has a closed end face and an open end face, and the open end face forms an adsorption end face. The motor 2 is installed on the closed end surface, and the fan blade 12 arranged in the cavity 11 is connected to the output shaft of the motor 2. The closed end surface is in an airtight state, and the fan blade 12 is arranged along the cavity of the cavity. The axes are distributed in a straight line, and the shell on the circumference of the opening end face may or may not contact the adsorbed object 3 during operation.

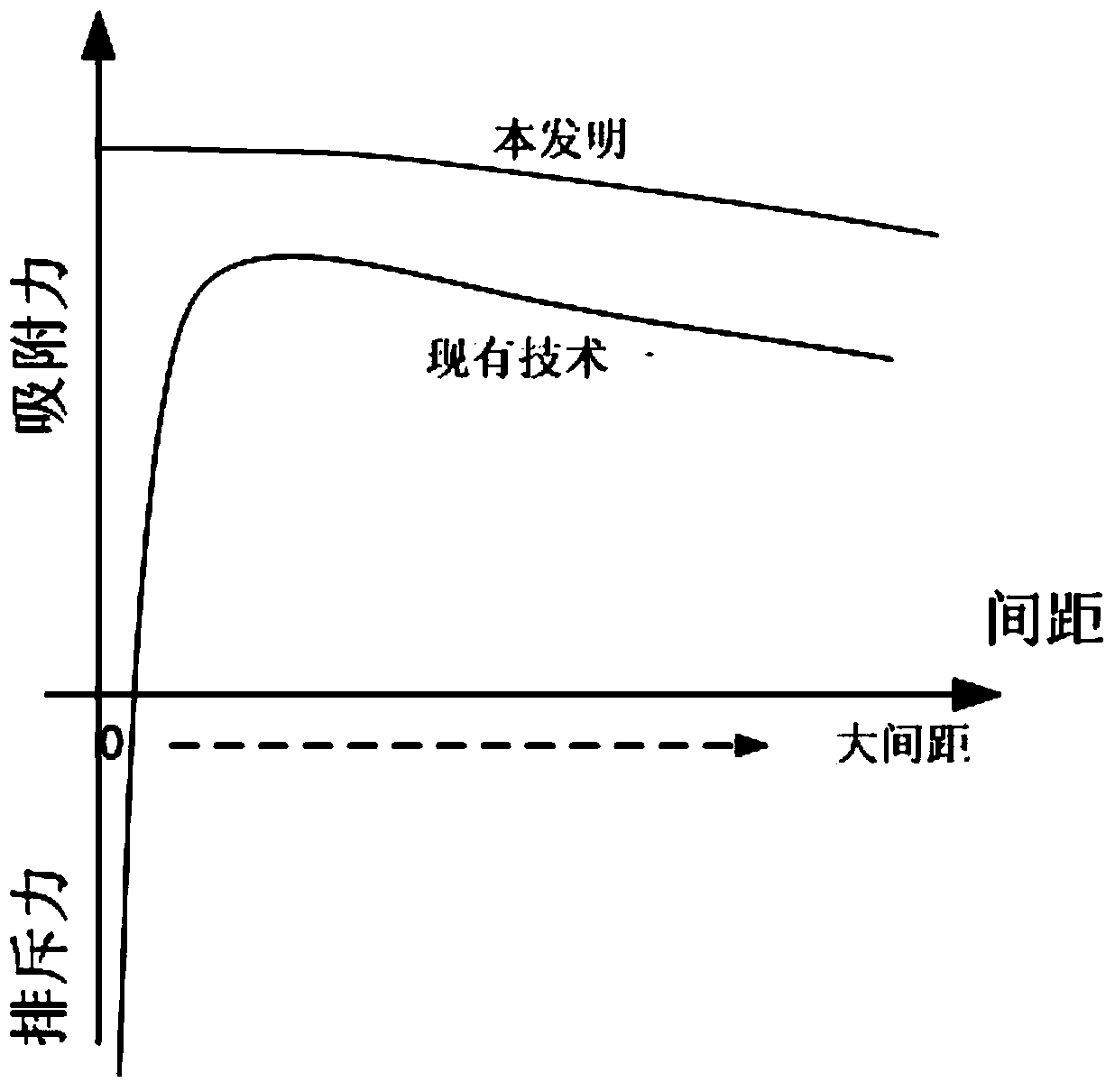

[0036] As mentioned above, the downdraft and crevice airflow of the prior art has an effect on the adsorption force. The present invention has no suction hole, and the fan blade has no bent part in the vertical direction, so it will not inhale air, nor wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com