Multi-rope friction lifter load identification method based on vibration analysis

A friction hoist and load identification technology, applied in mine lifting equipment, special data processing applications, instruments, etc., can solve problems such as high installation accuracy and reliability requirements, inability to reflect dynamic load changes, and influence of the hoisting system. , to achieve the effect of saving cumbersome process and a lot of investment, improving modal aliasing, and strong on-site operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution provided by the present invention, and the detailed implementation and specific operation process are given.

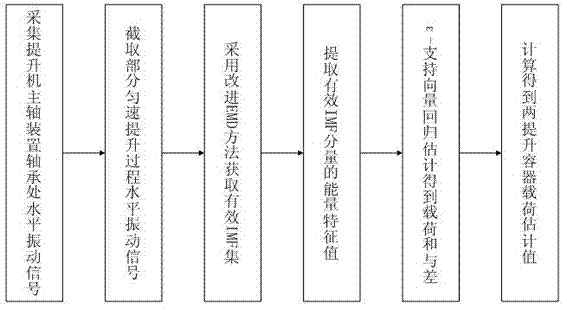

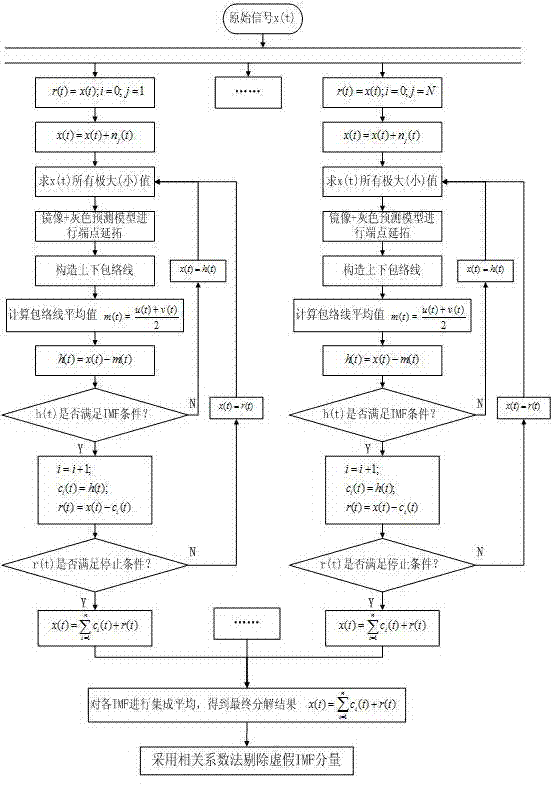

[0035] Such as figure 1 Said, implementing a vibration analysis-based multi-rope friction hoist load identification method provided by the present invention, the implementation method includes the following steps:

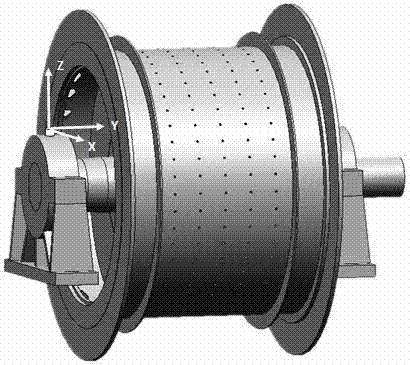

[0036] Step 1. Firstly, an acceleration sensor is installed on the top of the bearing seat on both sides of the main shaft of the multi-rope friction hoist, and the vibration signal in the horizontal direction of the bearing seat of the main shaft device of the hoist is obtained under the running state. The setting and acquisition position of the acceleration sensor are as follows: figure 2 As shown, the X direction is the horizontal direction. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com