Method for increasing top-coal recovery rate in primary mining period of fully-mechanized caving face

A fully mechanized caving face and recovery rate technology, applied in ground mining, earthwork drilling, underground mining, etc., can solve the problems of imperfect top-coal caving technology and low top-coal recovery rate, and achieve operability, The effect of reducing safety hazards and increasing economic income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the present invention, the present invention will be further clearly and completely described below in conjunction with the accompanying drawings.

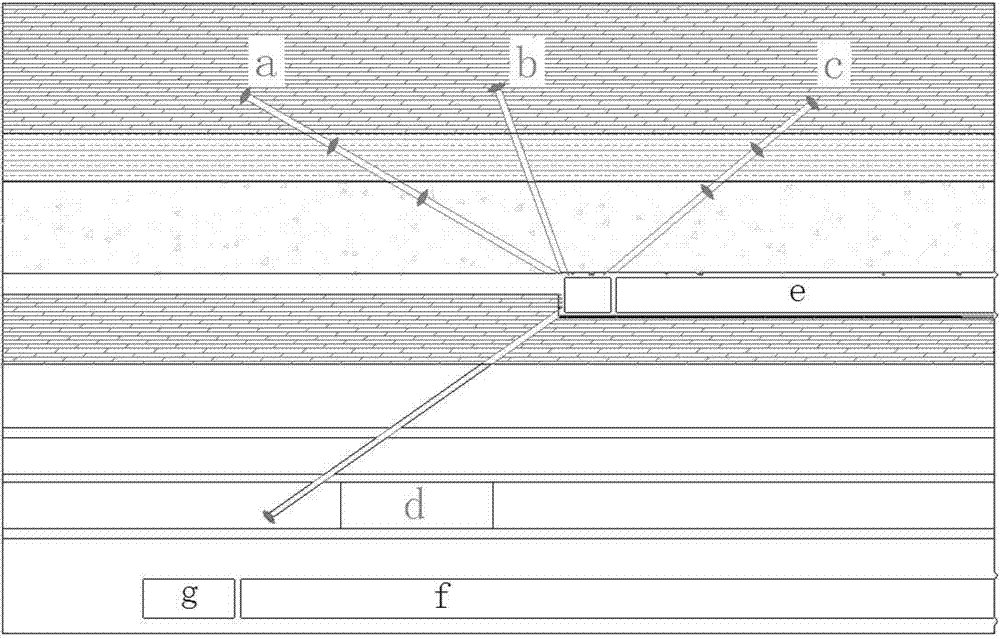

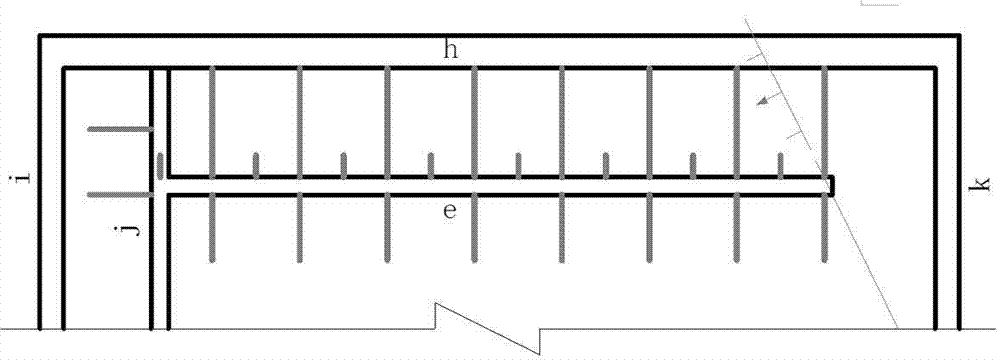

[0025] Such as figure 1 , figure 2 As shown, a method of improving the top-coal recovery rate during the initial mining of fully mechanized caving face of the present invention comprises the following steps:

[0026] (1) Before the initial mining of the working face, construct a hydraulic fracturing process roadway e in the direction of the belt channel k in the middle of the high pumping roadway j at a distance of 25m from the cut eye g, and construct several groups of hydraulic fracturing process roadway e in the hydraulic fracturing process roadway e Drilling, each group is specifically divided into four drillings a, b, c and d in different directions, of which three drillings a, b, c are arranged in the roof rock layer, and the other drilling hole d is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com