Complex load tester

A kind of load test and complex technology, applied in the field of pipeline test, can solve the problems of restricting failure mode, failure mechanism, and no problem, and achieve the effect of good reliability, good integration performance and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

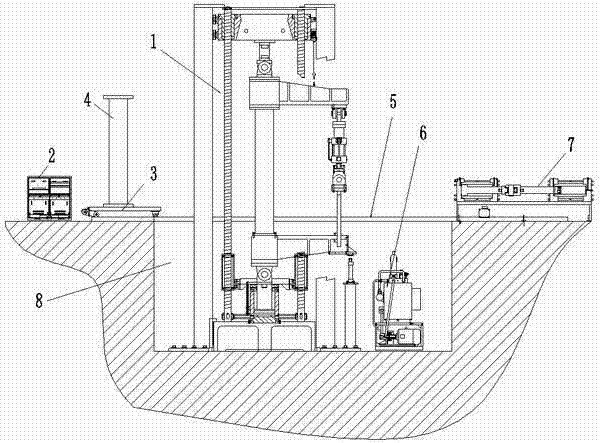

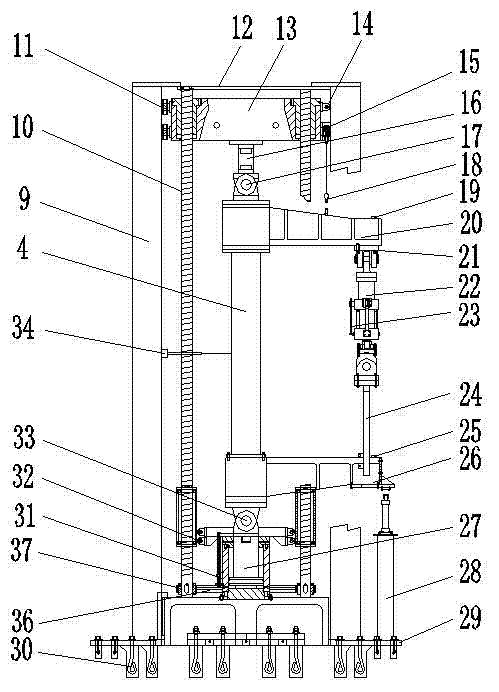

[0015] figure 1 , 2 A block diagram of a complex load testing machine is shown. In the figure, the complex load testing machine includes a main engine 1 and a combined hydraulic source 6 arranged in a pit 8, an electronic control computer 2, a sample transport trolley 3, an internal pressure loading device 7 and a measurement control system. The main engine adopts a frame structure formed by connecting four reaction frames 9 to the top fixed beam 12 and the base 29 respectively, an axial force loading device and a bending moment loading device.

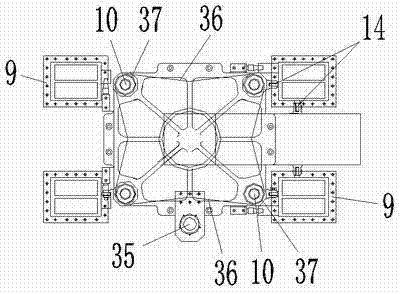

[0016] The axial force loading device is set in the frame structure. The movable beam 13 is driven by a hydraulic motor 35 through four lead screws 10 and lifted up and down along the reaction force frame 9 by means of rollers 14. The lower part of the movable beam 13 is connected with a 6000KN sensor 16 and an upper ball joint in turn. 17 and upper curved beam 20. Mounting bases for four lead screws 10 and hydraulic motors 35 are ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap