Modified asphalt coiled material forming and thickness control device capable of preventing tire bases from being broken by blowing

A technology of modified asphalt and thickener, which is applied to devices and coatings that apply liquid to the surface, can solve the problems of the tire base fabric being stuck, the thickness of the coil is inconsistent, and blocked, so as to prevent scratches and achieve uniform thickness. , better heat resistance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

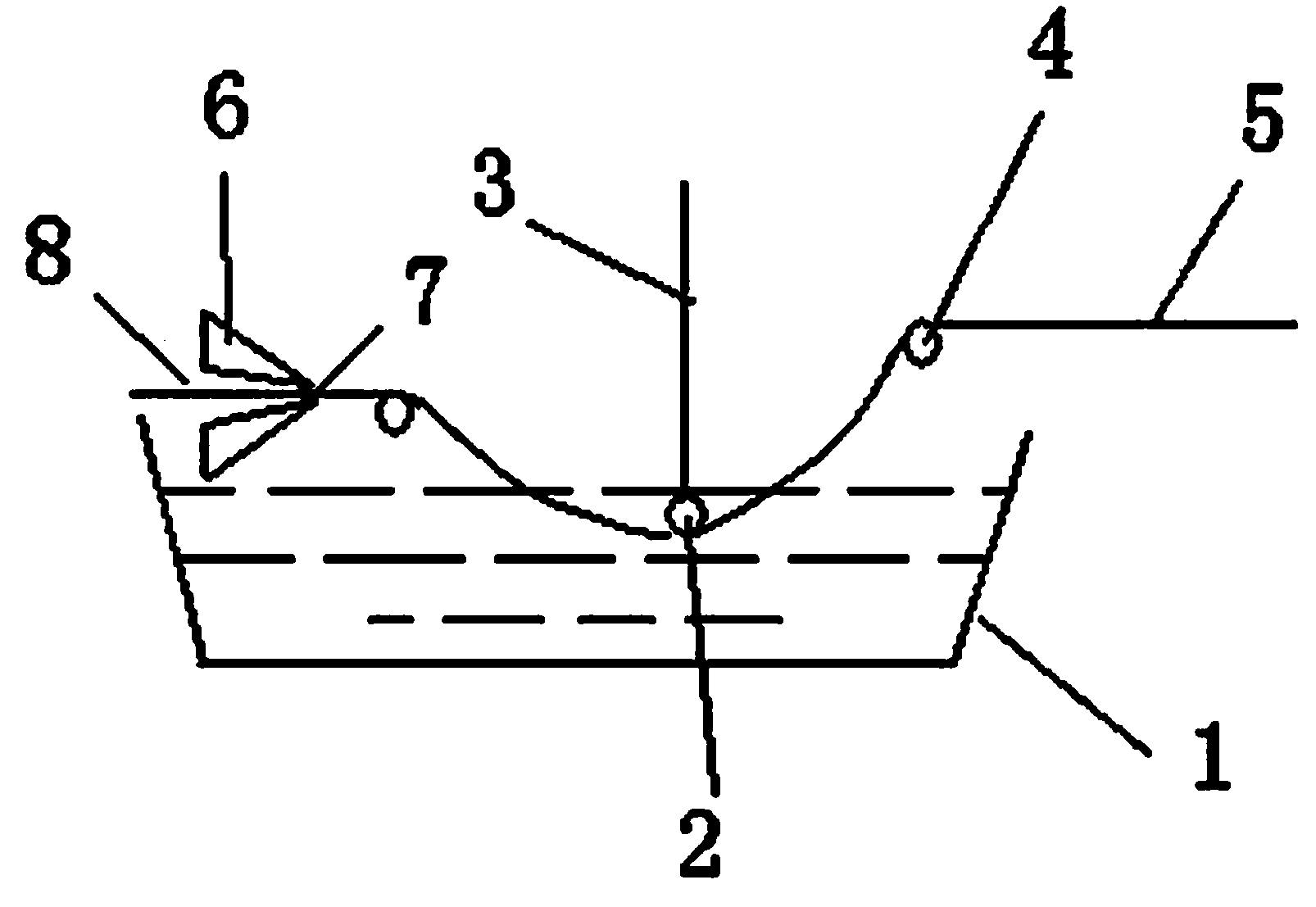

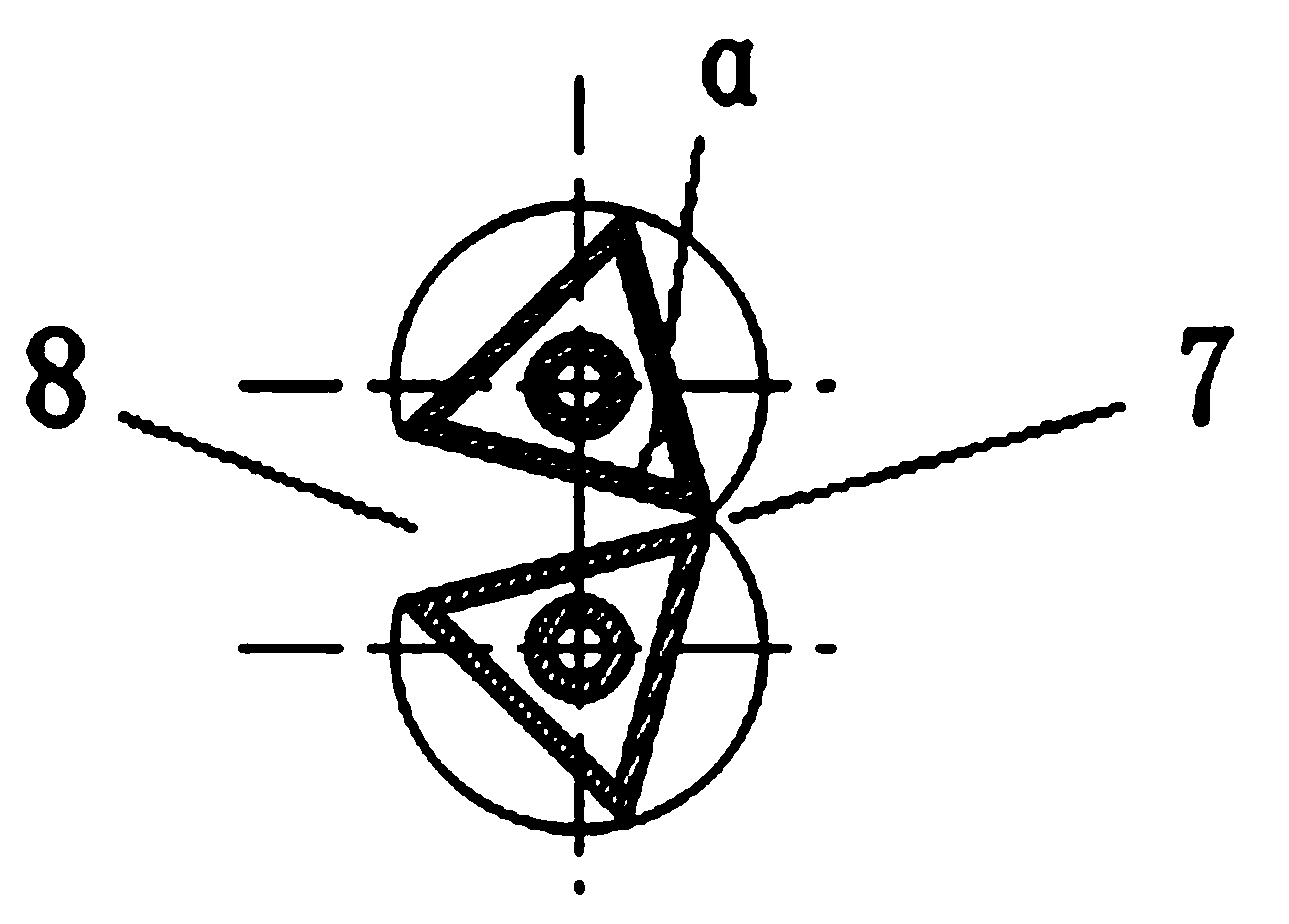

[0010] A modified asphalt coil forming thickness control device for preventing tire base scraping, the forming thickness control device 6 includes two thickness regulators arranged up and down opposite to each other, characterized in that the two thickness regulators are wedge-shaped structures , and the front ends of the two wedge-shaped thickness regulators are arranged oppositely, and a first gap 7 is arranged between the front ends of the two thickness regulators, and the first gap 7 is the input end of the forming thickness controller, A second gap 8 is provided between the rear ends of the two thickness controllers, and the second gap 8 is the output end of the forming thickness controller, and the first gap 7 is smaller than the second gap 8 . According to a specific embodiment of the present invention, the front end of the wedge-shaped thickness adjuster forms an acute angle α of 50-70 degrees. At least one of the two thickness adjusters is provided with a gap adjustin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com