Rear axle housing set square stamping die

A triangular plate and stamping die technology, which is applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of slow production speed, large amount of material waste, unreasonable structure, etc., and achieve reduced manufacturing costs and high precision of shape and size , the effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

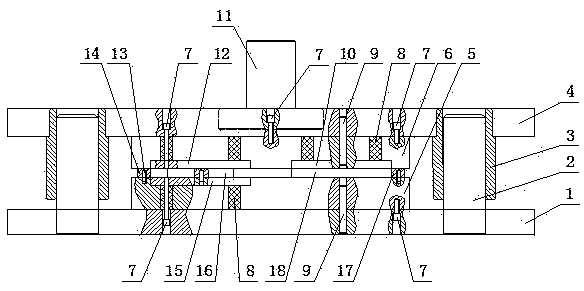

[0011] The stamping die of the rear axle housing triangular plate is composed of a lower mold base 1, a guide column 2, a guide sleeve 3, an upper mold base 4, a lower mold 5, and an upper mold 6, and the two sides of the lower mold base 1 and the upper mold base 6 pass through the guide column 2 and the guide sleeve 3 are movably connected, and there is a gap between the guide sleeve 3 and the lower mold base 1, and the upper mold base 6 can slide up and down through the guide post 2 and the guide sleeve 3. The lower mold base 4 is fixed with the lower mold 5 and the movable block c15 through the locking positioning pin 9 and the inner hexagon screw 7, and the upper mold base 4 is fixed with the upper mold 6, Movable block a10 and movable block b12, mold handle 11 is equipped with in the upper middle part of upper mold base 4; Positioning block a14, positioning block b16 and positioning block c17 are equipped with on the lower die 5 through countersunk head screw 13; Described...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com