Check ring for shaft and machining method of check ring for shaft

A technology of a shaft retaining ring and a processing method, which is applied in the field of mechanical parts, can solve the problems of small contact area of the shaft retaining ring, large outer diameter tolerance, and ejection of the shaft retaining ring, and achieves a large contact area and uniform force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

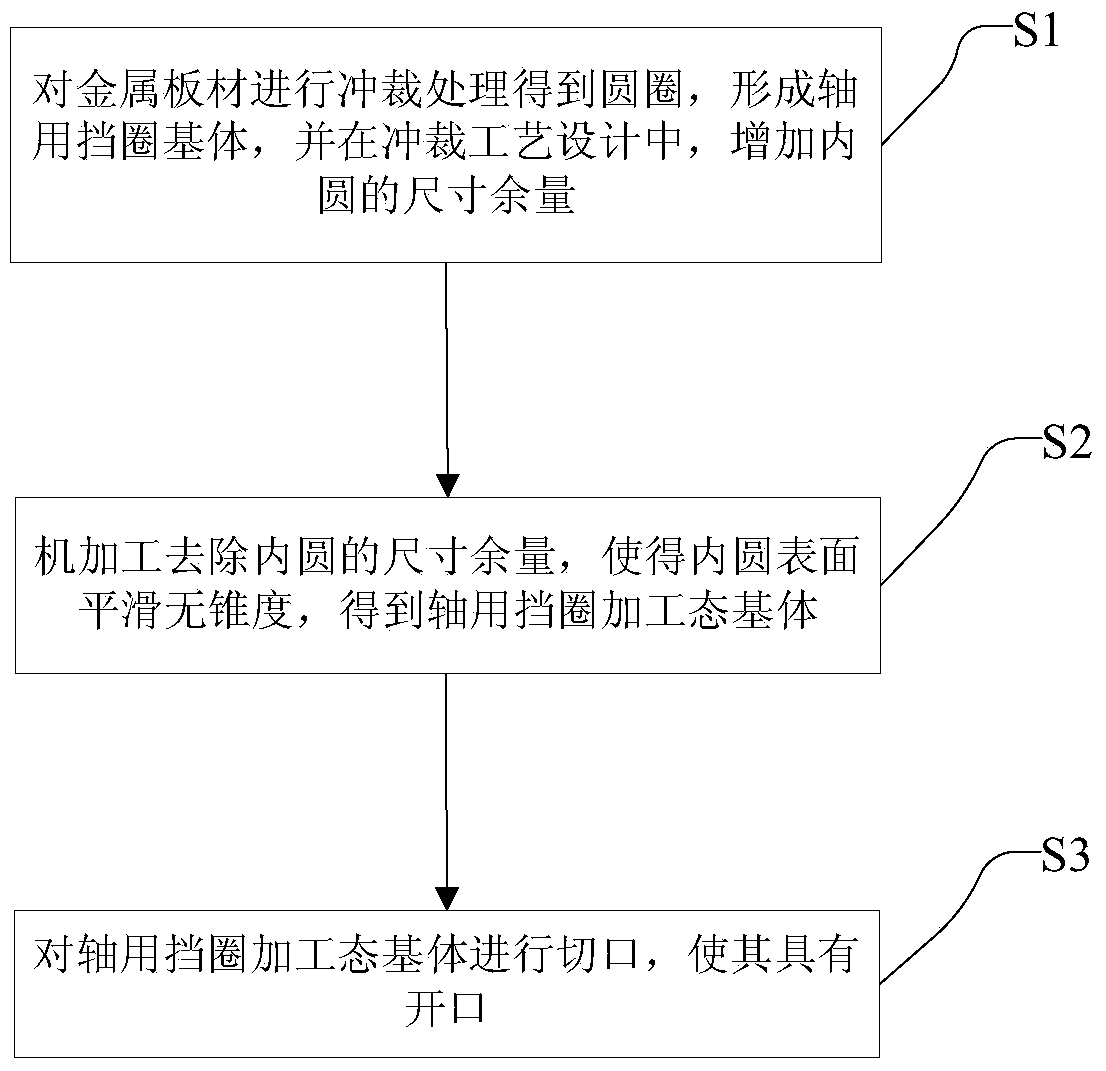

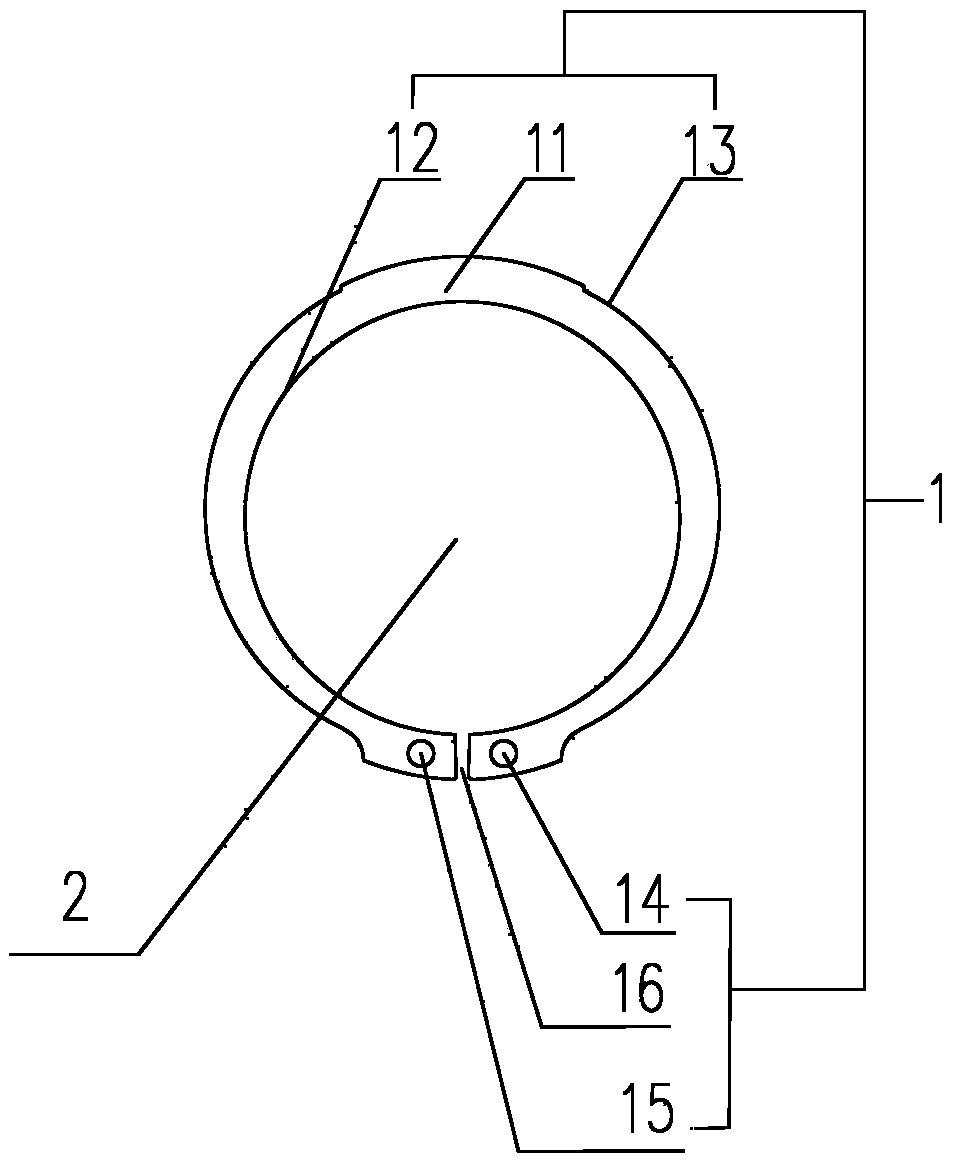

[0017] Such as figure 1 as shown, figure 1 It is a schematic flow chart of a processing method for a shaft retaining ring proposed by the present invention; figure 2 It is a structural schematic diagram of a shaft retaining ring proposed by the present invention.

[0018] refer to figure 1 , a method for processing a retaining ring for a shaft proposed by the present invention, comprising the following steps:

[0019] S1. Punching the metal sheet to obtain a circle to form the base of the retaining ring for the shaft, and increase the size margin of the inner circle in the blanking process design;

[0020] S2. Machining removes the size allowance of the inner circle, so that the surface of the inner circle is smooth and has no taper, and the processed state matrix of the shaft retaining ring is obtained;

[0021] S3. Cutting the processed base of the shaft retaining ring so that it has an opening.

[0022] refer to figure 2 According to the present invention, a shaft r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com