Clamping device special for crank part grinding outer arc

A technology for clamping equipment and grinding outer arcs, which is applied in the direction of grinding/polishing equipment, metal processing equipment, grinding machines, etc., which can solve the problems of slow processing speed, difficulty in ensuring dimensional accuracy, and low efficiency, and achieve long service life and shortened The effect of processing time and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

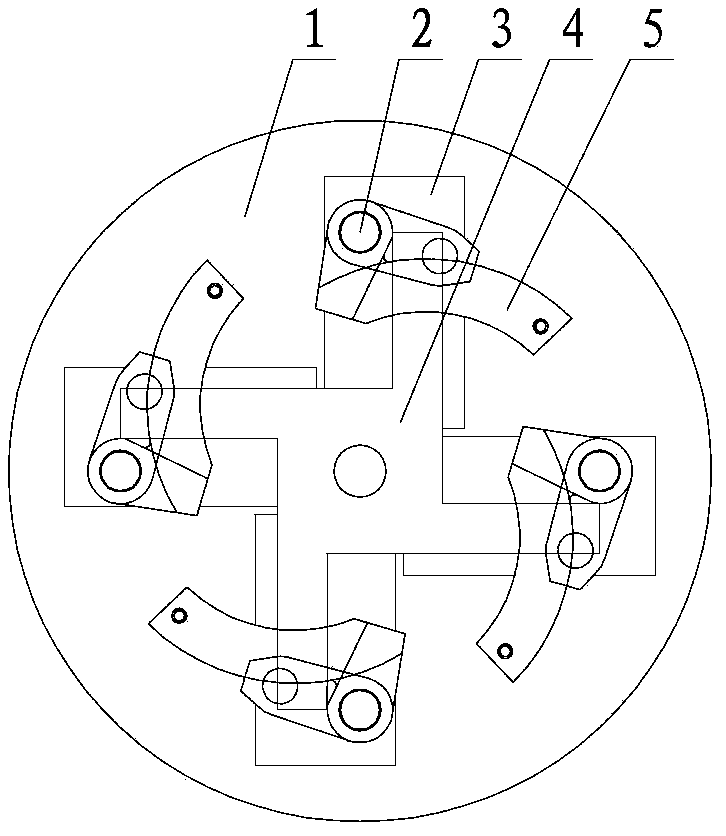

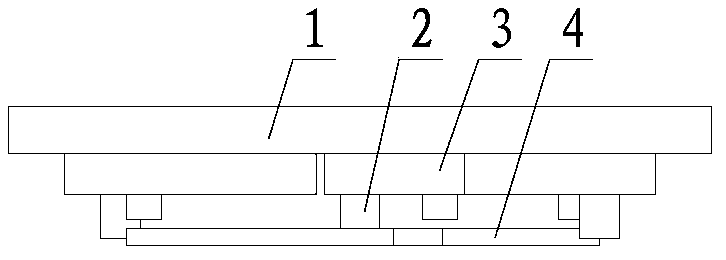

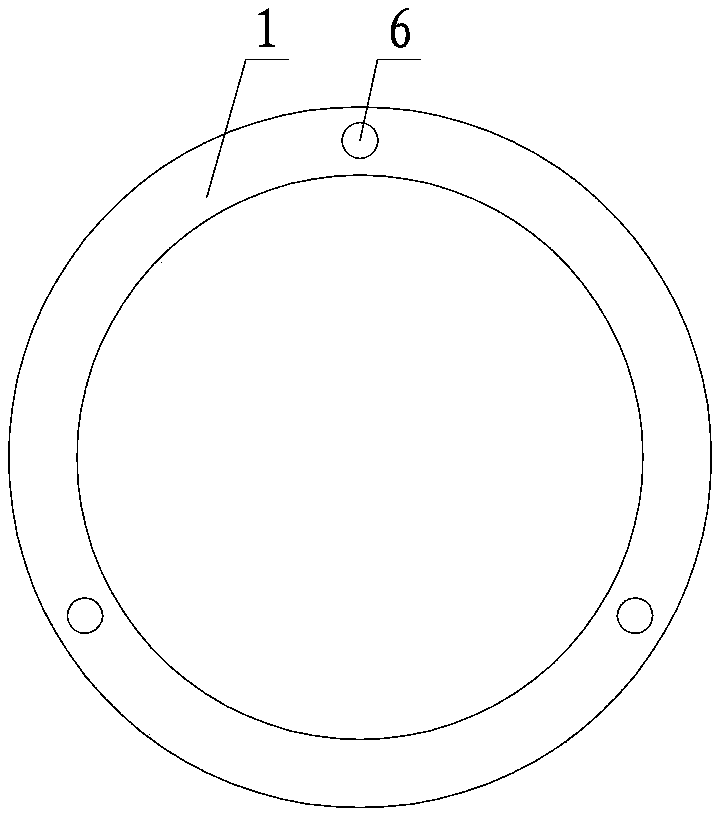

[0018] A special clamping device for grinding outer arcs of crank parts, including a flange 1, three mounting holes 6 are evenly distributed on the back of the flange, so as to install the flange on a machine tool.

[0019] A group of positioning blocks 3 are evenly distributed on the upper surface of the flange, and a positioning pin 2 for inserting a workpiece is formed on each positioning block. The number of positioning blocks is not limited, and there are four in this embodiment. A pressing plate 4 is installed on the flange, and the pressing plate is located above the positioning block, which can play the role of positioning and pressing the workpiece 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com