Shot derusting machine for inner wall of super-long pipeline

A rust removal machine and pipeline technology, which is applied in abrasive jet machine tools, used abrasive treatment devices, abrasive materials, etc., can solve the problems affecting workers' health and safety, high economic cost of comprehensive rust removal, and high labor intensity for workers. , to achieve the effect of saving dust removal equipment, saving production preparation time, and saving the link of recycling steel grit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

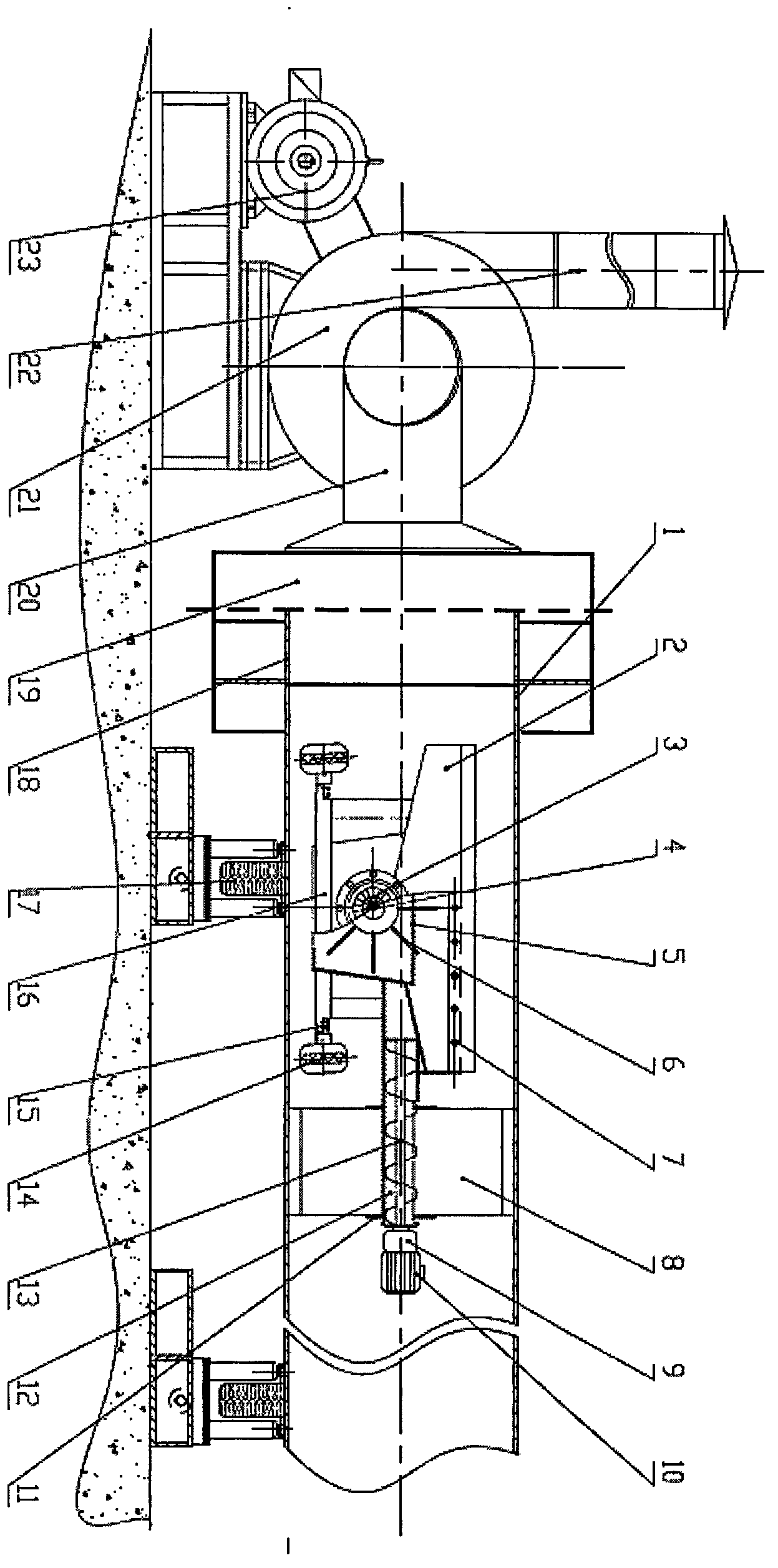

[0017] see figure 1 :

[0018] The steel pipe 1 to be derusted is placed on the rotating power bracket 17 of the steel pipe, and one end of the steel pipe 1 to be derusted is placed in the trolley transition cabin 18, dust collection box and dust filter device 19, and the trolley transition cabin 18 is connected with the dust collection box and dust filter. The filtering device 19 is connected to the air induction pipe 20, the dust removal induced draft fan 21, and the exhaust air duct 22 in sequence. Driven by the fan power motor 23, the dust removal work can be carried out; the sand storage box 2 is connected with the steel sand recovery wing device 12 , in this recovery wing device 12, be provided with steel sand collecting auger conveying mechanism 13; Derusting machine main frame 16 is provided with derusting machine walking wheel 14, and angle adjustable walking wheel support frame 15, in derusting machine main The sand storage box 2 is installed on the frame 16; the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com