Lifting transmission rail

A lifting drive and track technology, applied in the directions of conveyor objects, transportation and packaging, support frames, etc., can solve the problems of difficulty in ensuring the smooth transportation of parts, insufficient stability of the adjustable drive track, and easy sliding of the transported parts. To achieve the effect of simple structure, convenient operation and easy manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

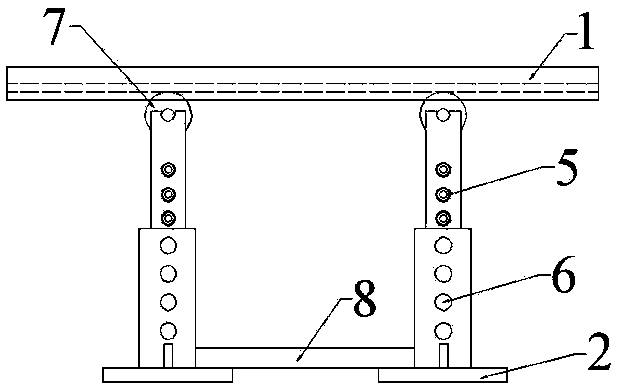

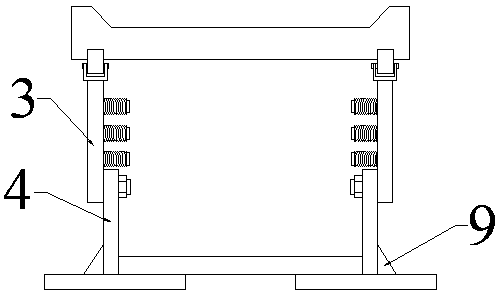

[0026] Such as figure 1 , figure 2 As shown, a lifting transmission track includes a transmission plate 1, a bottom plate 2, a first connecting plate 3, a second connecting plate 4, and a pulley 7. The upper surface of the transmission plate 1 is a trapezoidal concave surface, and the two sides of the lower surface are along the transmission direction. A chute is provided; one side of the first connecting plate 3 is provided with studs 5 arranged at equal intervals, and the top of the first connecting plate 3 is "U"-shaped; the pulley 7 is connected in the "U" shape by bolts, And the top of the pulley 7 is tangent to the upper surface of the chute of the transmission plate 1; there are four pulleys 7, which are evenly distributed on the lower part of the transmission plate 1; the second connecting plate 4 is provided with the studs 5 on the first connecting plate 3 N screw holes 6; the bottom surface of the second connecting plate 4 is fixed on the bottom plate 2.

[0027]...

Embodiment 2

[0030] Same as embodiment 1, the difference is that the number of pulleys 7 is 6, and the number of screw holes 6 and studs 5 are both 3, which can ensure a more stable transmission plate.

Embodiment 3

[0032] Same as embodiment 1, the difference is that the number of screw holes 6 and studs 5 are both five, which can adjust the height in a wider range.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com