Steel alloy, compressor slide sheet and preparation method of compressor slide sheet

A steel alloy and compressor technology, applied in the field of compressors, can solve problems such as tip wear, high process cost, and high raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

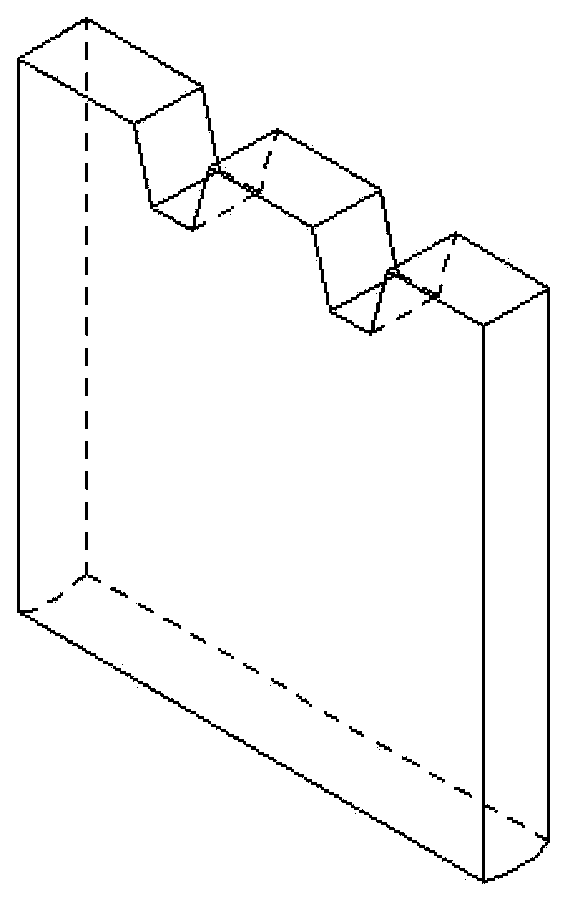

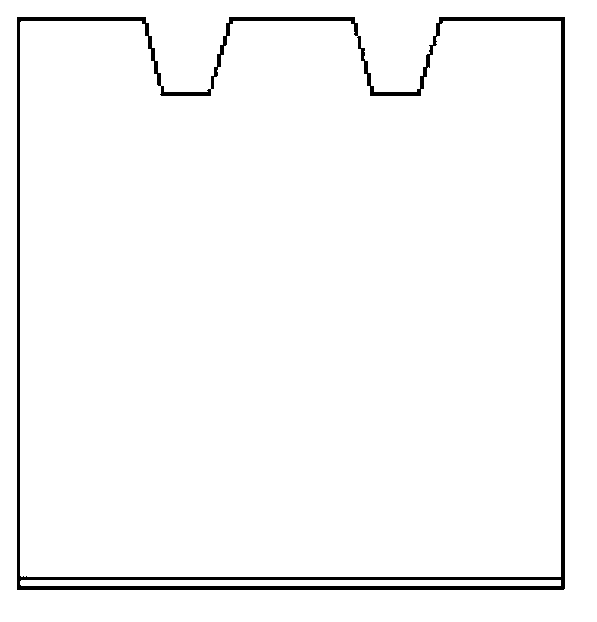

Image

Examples

Embodiment 1

[0038] 1. Carry out smelting and casting according to the following composition to obtain a steel ingot: 1.0% by weight of C, 0.8% by weight of Si, 1.0% by weight of Mn, 1.2% by weight of Mo, 7.0% by weight of Cr, 2.3% by weight of W, 0.6% by weight % of V, 0.8% by weight of Al, of which P≤0.03% by weight, S≤0.03% by weight, and the rest is Fe;

[0039] 2. Anneal the obtained smelted product (steel ingot) before hot rolling, wherein the annealing furnace temperature is 910 degrees Celsius, the annealing speed is 30 degrees Celsius per minute, and the hardness is 255HB;

[0040] 3. According to the precision required by the width and height of the slide, the annealed steel ingot is forged and then hot-rolled into a strip plate;

[0041] 4. Cut into sliding pieces according to the size requirements, and mill grooves;

[0042] 5. Quenching and tempering the cut slides in turn;

[0043] Quenching treatment: furnace temperature 1100 degrees Celsius, holding time 8 minutes; temper...

Embodiment 2

[0049] 1. The sliding sheet of this embodiment is smelted and cast according to the following composition to obtain a steel ingot: 0.9% by weight C, 1.6% by weight Si, 1.3% by weight Mn, 1.0% by weight Mo, 7.0% by weight Cr, 2.2% by weight W, 0.6% by weight V, 0.9% by weight Al, 0.01% by weight Re, wherein P≤0.03% by weight, S≤0.03% by weight, and the rest is Fe.

[0050] 2. Anneal the obtained smelted product (steel ingot) before hot rolling, wherein the annealing furnace temperature is 890 degrees Celsius, the annealing speed is 16 degrees Celsius per minute, and the hardness is 260HB;

[0051] 3. According to the precision required by the width and height of the slide, the annealed steel ingot is forged and then hot-rolled into a strip plate;

[0052] 4. Cut into sliding pieces according to the size requirements, and mill grooves;

[0053] 5. Quenching and tempering the cut slides in turn;

[0054] Quenching treatment: furnace temperature 1090 degrees Celsius, holding tim...

Embodiment 3

[0057] 1. The sliding sheet of this embodiment is smelted and cast according to the following composition to obtain a steel ingot: 0.9% by weight C, 1.5% by weight Si, 1.0% by weight Mn, 1.0% by weight Mo, 6.0% by weight Cr, 2.2% by weight W, 0.6% by weight V, 0.4% by weight Al, 0.08% by weight B, 0.3% by weight Ti, wherein P≤0.03% by weight, S≤0.03% by weight, and the rest is Fe.

[0058] Steps 2-5 are the same as steps 2-5 in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap