Large-tonnage anchor rod simple static-pressure-pile pressing frame

A technology of anchor static pressure piles and pressure pile frames, which is applied to sheet pile walls, buildings, and foundation structure engineering, etc., which can solve the problems of high cost, difficulty in handling, and high requirements for pile pressure construction sites, and achieve economical cost and light equipment , the effect of easy transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

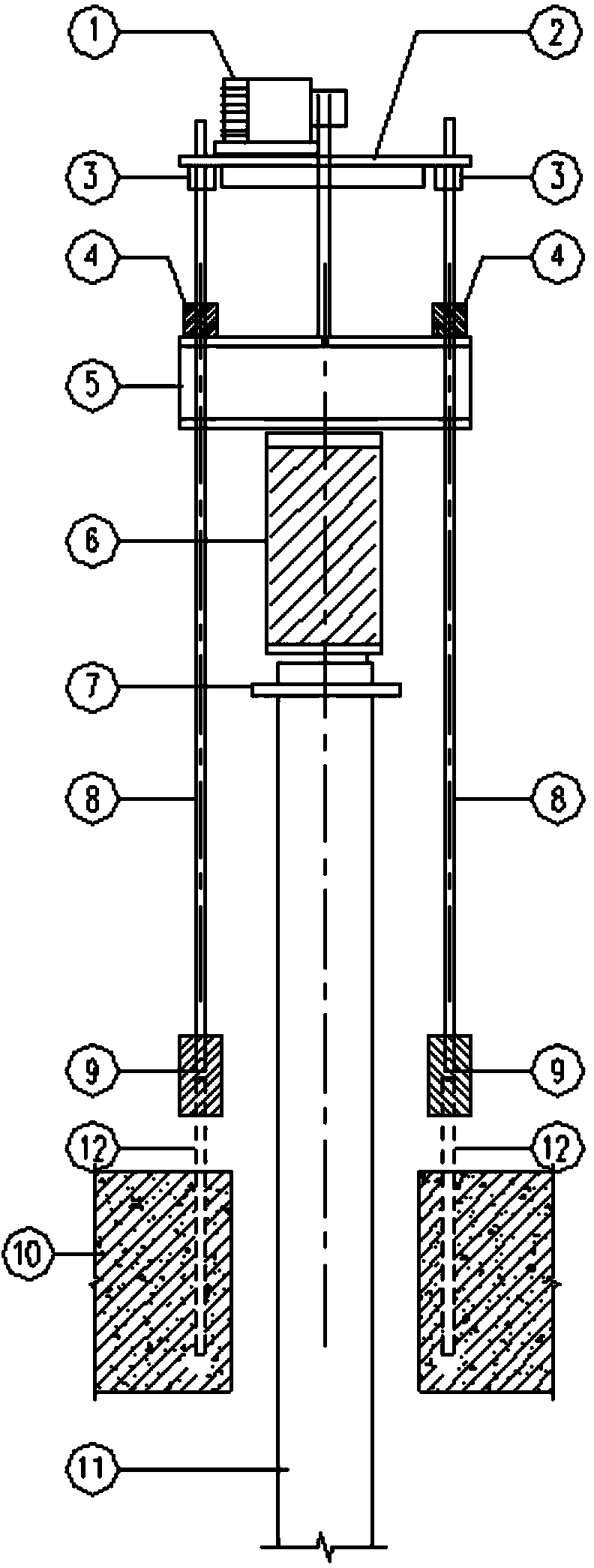

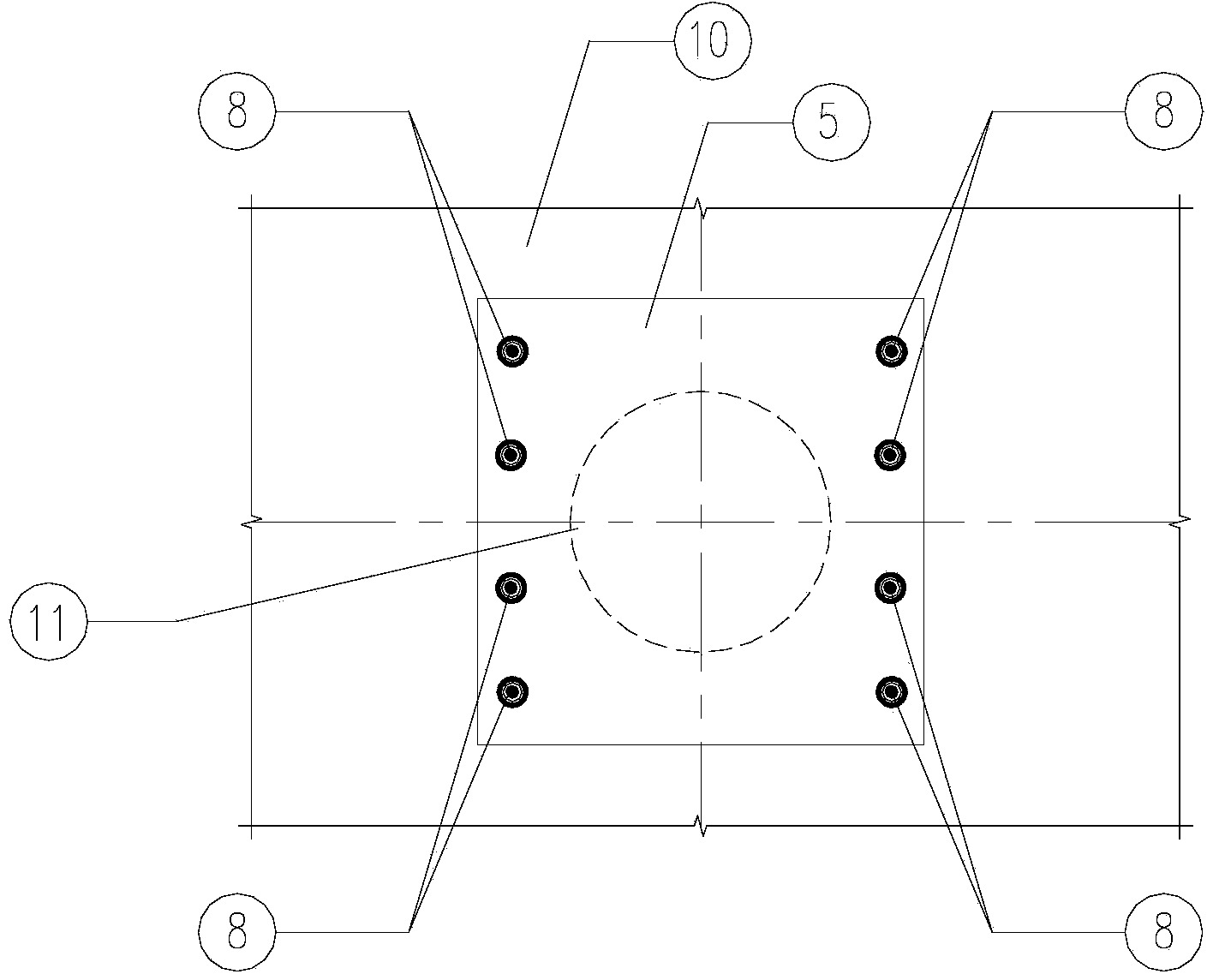

[0014] 1. On both sides of the pile hole of the large-tonnage anchor static pressure pile, according to the requirements of the drawing, 4 (8 in total) finished-rolled threaded steel bars with a diameter of 32mm are symmetrically pre-embedded or implanted as anchor rods, and the cap surface is exposed by 30cm.

[0015] 2. After the strength of the concrete meets the requirements of the pile pressure or the pull-out resistance of the implanted finished-rolled threaded steel bars meets the requirements, the finished-rolled threaded steel bars with a diameter of 32 mm (length 2 meters to 6 meters) consistent with the number of pre-embedded anchors will be passed through the special The connector is firmly connected with the pre-embedded fine-rolled threaded steel anchor rod.

[0016] 3. From the top of the fine-rolled threaded steel bar, penetrate the pressure pile reaction plate (the jack and the reaction plate are connected as one), M32 tool nuts, M32 fixing nuts, steel plates f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com