High-pressure three-position valve

A three-position valve and high-pressure technology, which is applied in the field of solenoid valves, can solve the problems of not separating the working air circuit and the control air circuit, slow response, short life, etc., and achieve compact structure, fast reversing action, and sensitive response. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

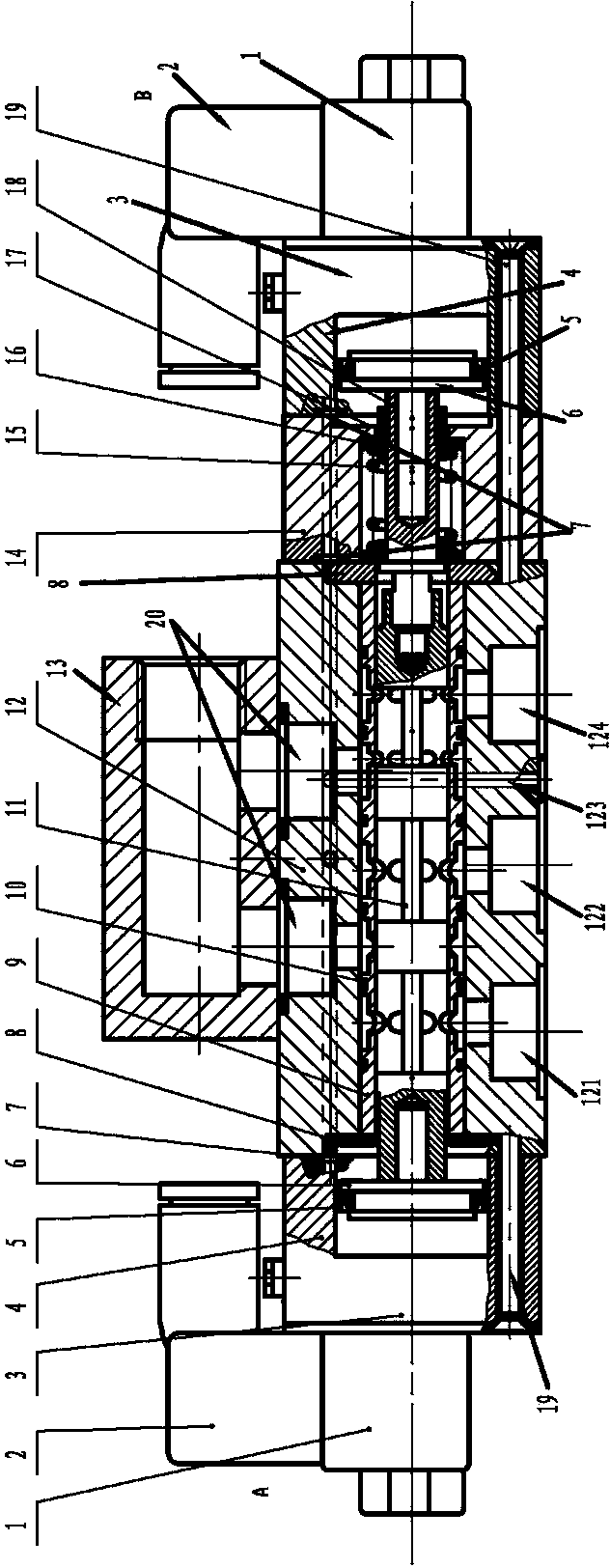

[0010] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, the present invention consists of a valve body 12, a valve sleeve 9, a valve stem 11, a return seat 14, a spring 15, a spring seat 16, a connecting rod 18, a piston 6, a pilot seat 4, a pilot assembly 3, and a coil 1. , the center of the valve body 12 is placed with a valve sleeve 9, the valve body 12 and the valve sleeve 9 are sealed with a sealing ring 10, and the two ends are positioned with a gasket 8, and the gasket 8 is located in the valve body 12; the valve sleeve 9 There is a valve stem 11 that can move back and forth in the valve sleeve 9 in the center of the interior; the bottom of the valve body 12 is provided with a first working air pressure port 121, a second working air pressure port 122, a control air pressure port 123 and an exhaust port in sequence. 124 , two air vents 20 are opened on the upper part of the valve body, and a working cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com