A reliability test method for axial piston pump and motor

A technology of axial piston motor and axial piston pump, which is used in fluid pressure actuation system testing, fluid pressure actuation device, mechanical equipment, etc., can solve the problem of high energy consumption, less sample, axial piston pump And the problem of long reliability test time of motor, etc., to reduce test time and increase test samples.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

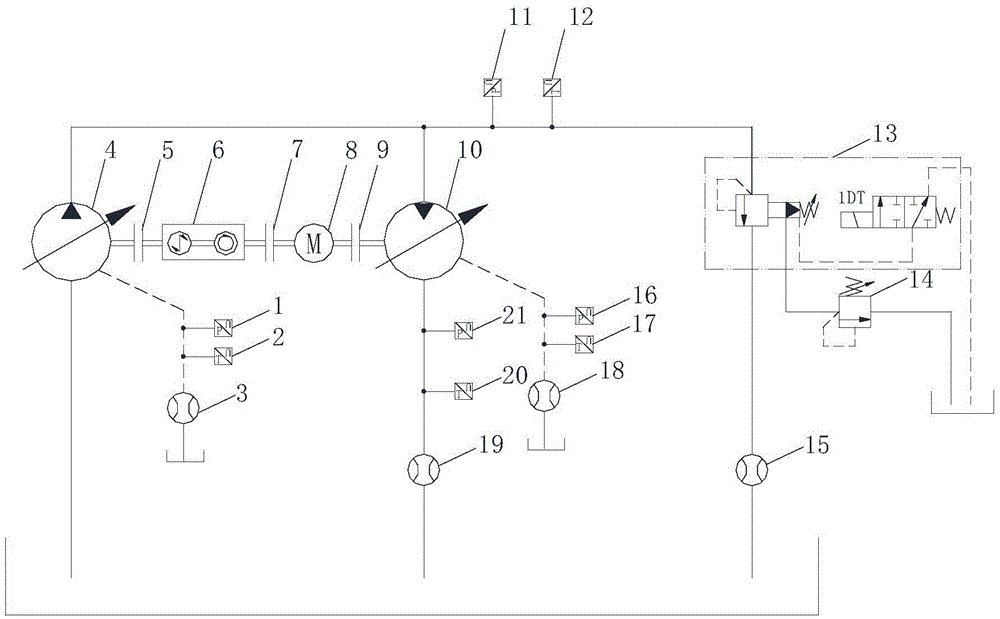

[0008] Axial piston pump and motor reliability test method, combined with figure 1 , the tested axial piston pump 4 outputs pressure oil under the drive of the frequency conversion motor 8, and the tested axial piston motor 10 drives the frequency conversion motor 8 to rotate under the drive of pressure oil to complete power recovery; the electromagnetic overflow valve 13 is the hydraulic system pressurization; the axial piston pump 4 and the axial piston motor 10 are all used as the tested objects; Four sets of pressure, temperature sensors and flowmeters, and the torque tachometer 6 installed at the input shaft of the tested axial piston pump 4 collect relevant data, and calculate the axial column according to the collected data and related calculation formulas. Reliability parameters of plug pumps and motors.

[0009] refer to figure 1 , carry out the reliability test on the hydraulic axial piston pump and motor through the reliability test hydraulic system device, the hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com