Shell body locking structure and lamp

A locking structure and housing technology, applied in the direction of lighting devices, components of lighting devices, light source fixing, etc., can solve the problems of thread seizure, inconvenient use and maintenance, easy occurrence of seizure, etc., and achieve high structural reliability , no safety hazard, easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

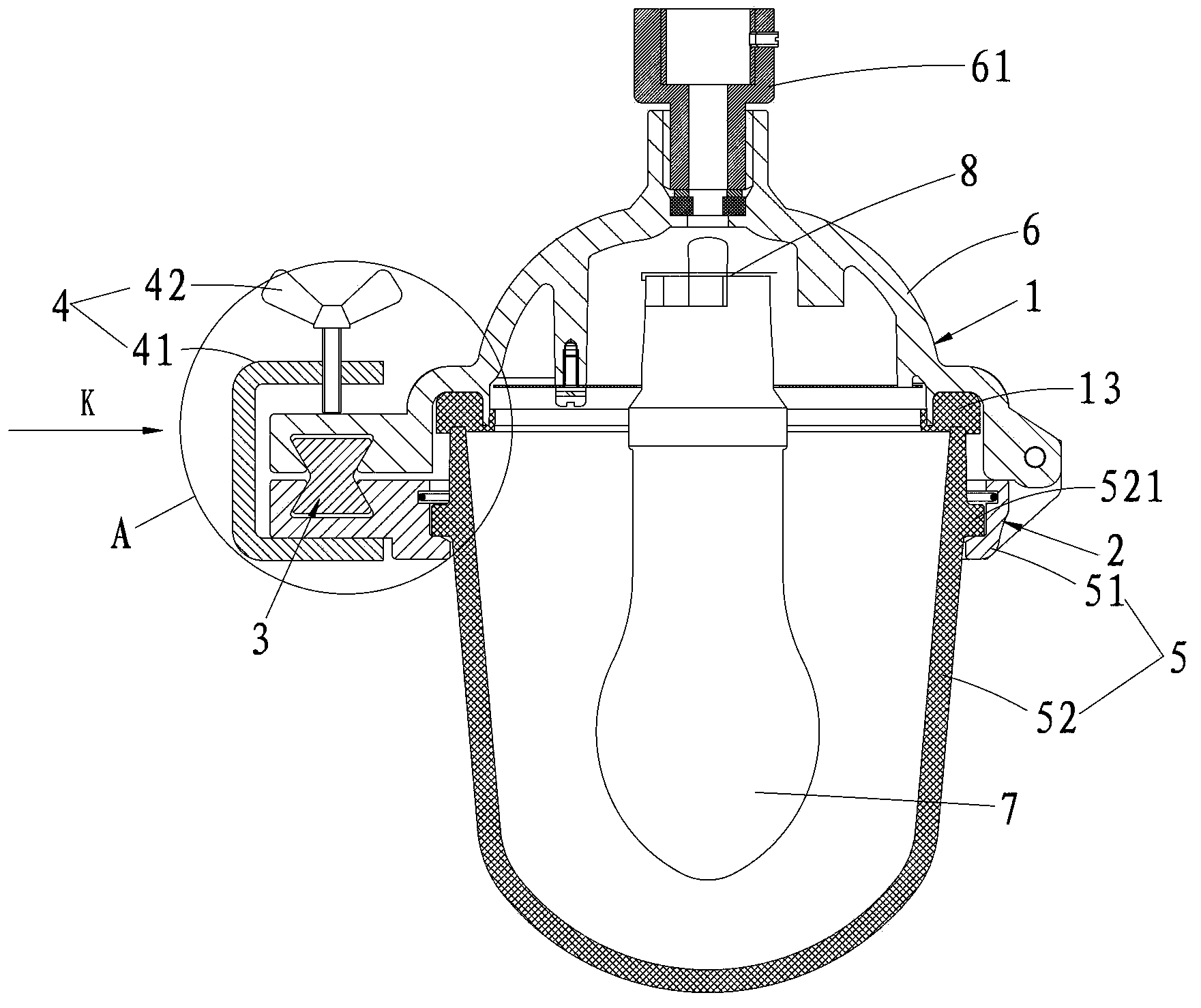

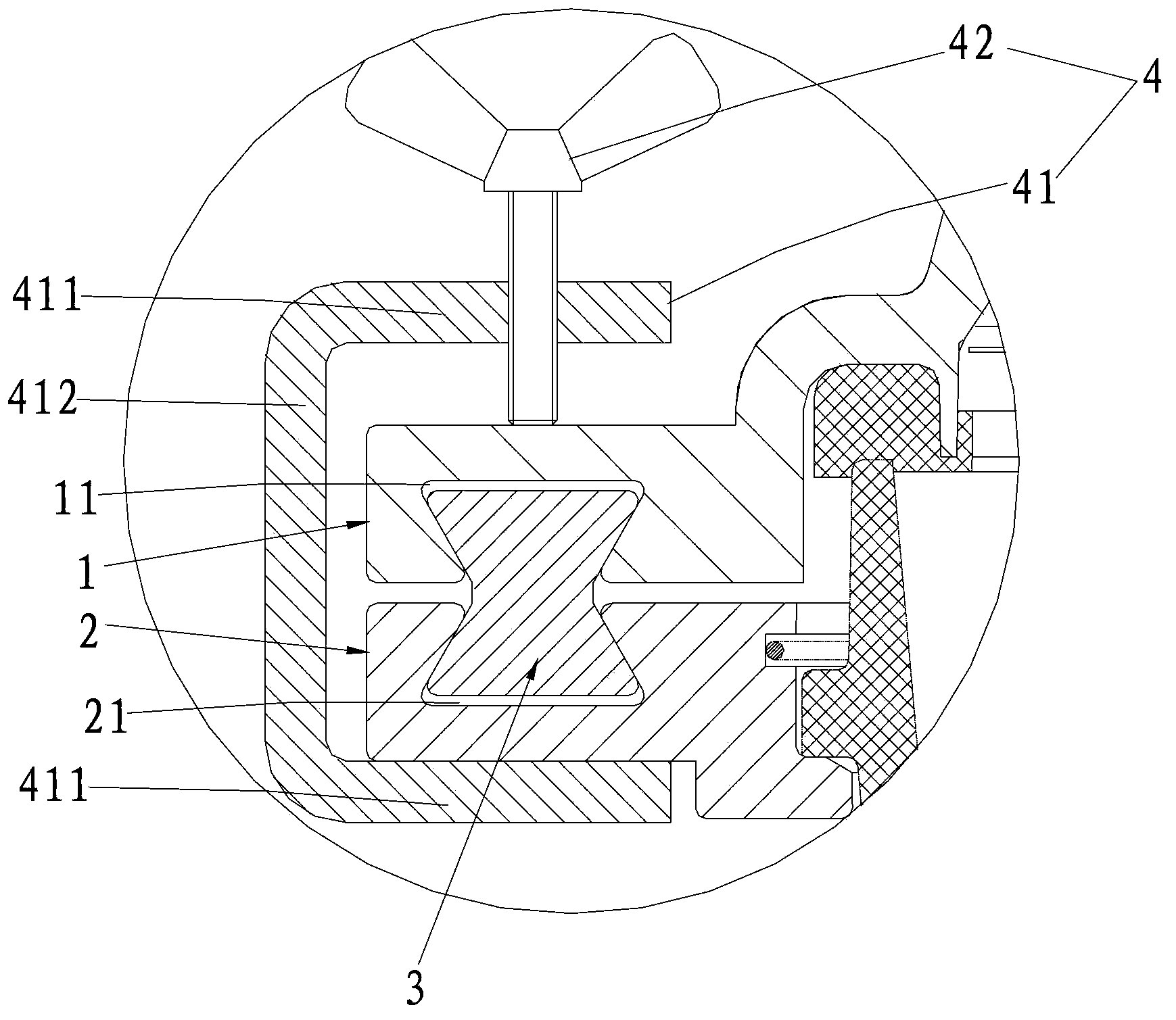

[0024] Such as figure 1 and figure 2 As shown, the housing locking structure provided by the embodiment of the present invention can be applied to products such as lamps and electrical boxes. In this embodiment, the above-mentioned locking structure is applied to a lamp to illustrate the beneficial effects of the present invention.

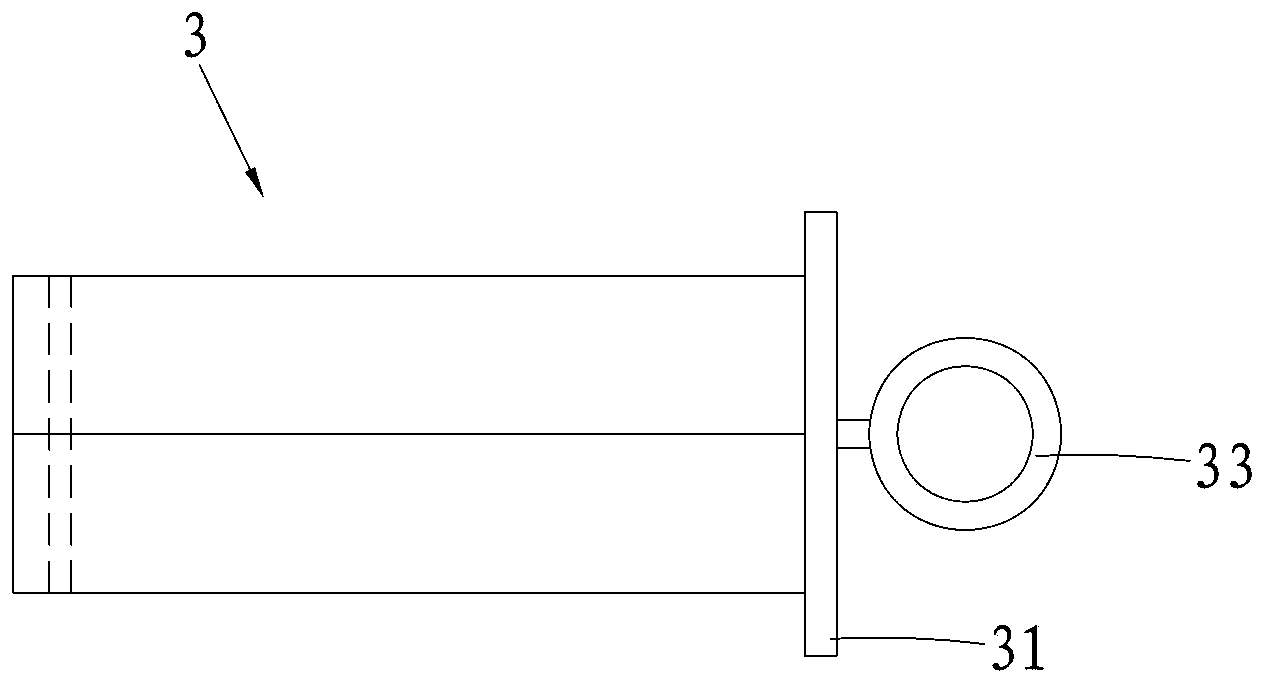

[0025] Such as figure 1 and figure 2 As shown, the above housing locking structure includes a first housing 1 and a second housing 2, the first housing 1 and the second housing 2 are oppositely arranged, and the first housing 1 is provided with a first undercut The slot 11, the second shell 2 is provided with a second undercut slot 21. The housing locking structure also includes a connector 3 that can be inserted into the first undercut groove 11 and the second undercut groove 21 at the same time. One end of the connector 3 is inserted into the first undercut groove 11, and the other end is inserted into the first undercut groove 11. In the...

Embodiment 2

[0037] Such as figure 1 and figure 2 As shown, the embodiment of the present invention provides a lamp, which has the housing locking structure as described in the first embodiment. Specifically, the above-mentioned lamp includes a lamp housing 6 , a lower housing 5 and a light emitting element 7 . The lamp housing 6 and the lower housing 5 are arranged facing each other and form an inner cavity for accommodating the light-emitting element 7 , a lamp holder 8 is fixed in the inner cavity, and the light-emitting element 7 is fixed on the lamp holder 8 . The lamp housing 6 is provided with a first undercut groove 11 , and the lower shell 5 is provided with a second undercut groove 21 , and the above-mentioned lamp also includes a connector that can be snapped into the first undercut groove 11 and the second undercut groove 21 at the same time 3. One end of the connector 3 is inserted into the first undercut groove 11, and the other end is inserted into the second undercut gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com