A one-way clutch for clearance adjustment

A one-way clutch and clearance adjustment technology, applied in one-way clutches, clutches, slack adjusters, etc., can solve the problems of low efficiency, easy failure of one-way clutches, slow response, etc., and achieve low-cost effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

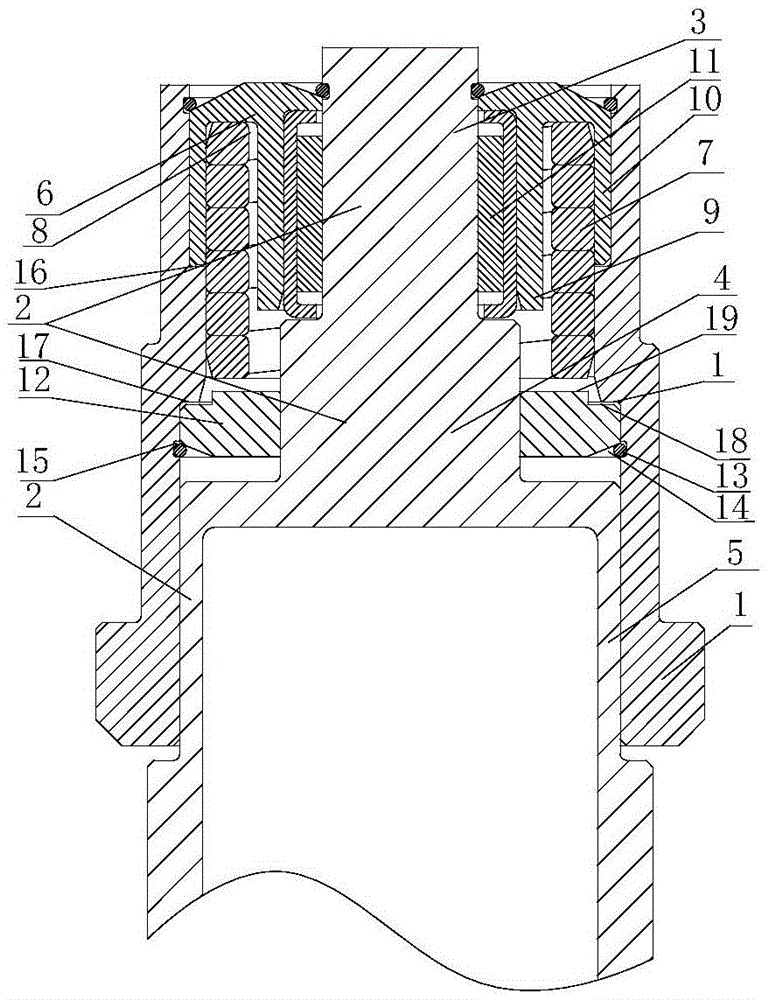

[0028] Please refer to figure 1 , a one-way clutch for gap adjustment according to the present invention, which includes a driving ring 1, a main shaft 2 is coaxially arranged in the driving ring, and the main shaft 2 includes a first part 3, a second part 4 and a third part 5, Its diameter increases sequentially. A transition ring 6 is provided between the main shaft 2 and the driving ring 1, and a housing cavity 8 is arranged inward along its end, thereby dividing it into an inner ring 9 and an outer ring 10, and the two are connected by the top of the transition ring 6 together.

[0029] The driving ring 1 is provided with a first step 16 in the direction of its axis, and the outer ring 10 of the transition ring 6 is located above the first step 16 and is in clearance fit with the driving ring 1 .

[0030] A one-way bearing 11 is provided between the inner ring 9 and the first part 3 of the main shaft 2 , and the one-way bearing 11 is in interference fit with the inner ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com