Pretension anti-buckling sleeve heat compensator and application thereof

A thermal compensator and sleeve-type technology, which is used in expansion compensation devices for pipelines, pipes/pipe joints/fittings, mechanical equipment, etc. The effect of reducing the risk of damage, ensuring work safety and reducing installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

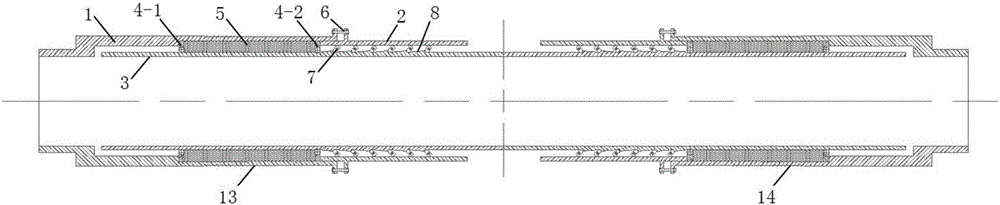

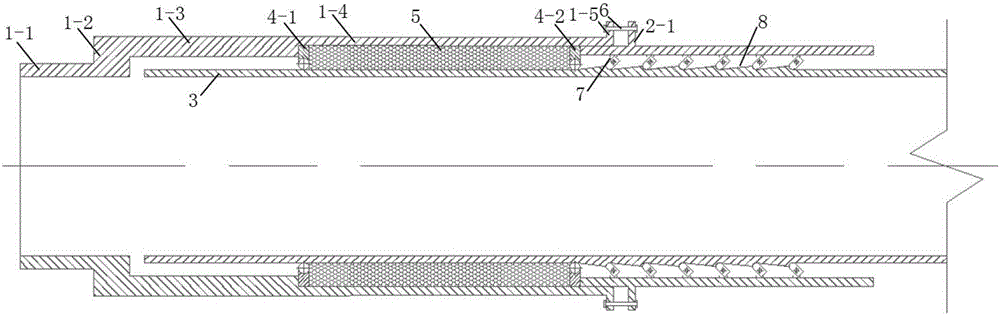

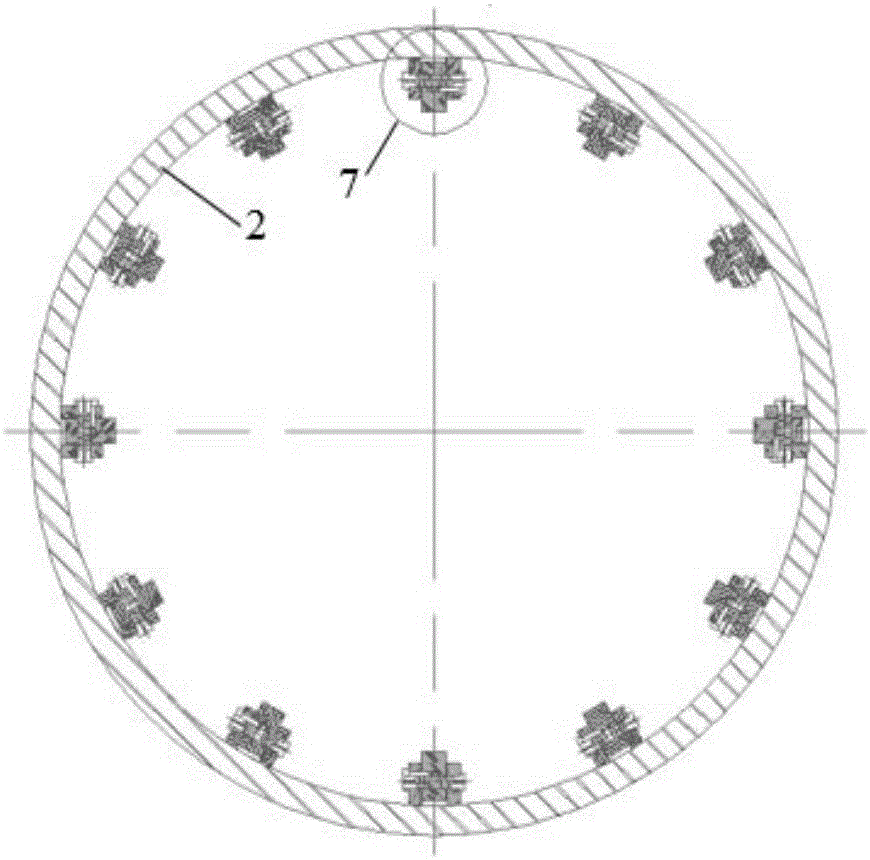

[0034] As shown in the drawings, the overall structure of the present invention is that the outer sleeve 1 and the outer pressure tube 2 with an axial stopper are connected by compression bolts 6 to form a left sleeve structure 13 and a right sleeve structure 14, and the outer wall is welded The inner tube 3 of the six-section axial limit groove 8 is inserted between the two sleeves, and the side sections 1-1 on both sides of the outer sleeve are welded with conventional pipelines, and the inner diameter of the inner tube and the outer sleeve (side sections 1-1 The inner diameter size of the thick section 1-2) is equal to the conventional pipeline size. An axial limit groove is welded on the outer wall of the inner tube, and the axial limit groove includes a straight plane 8-1 and a curved surface 8-2, and the curved surface has the same curvatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com