A device that converts circular rotation into linear reciprocating motion

A linear reciprocating motion and conversion technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problem that the relative frequency cannot be accelerated, achieve small lateral component force, reduce wear and heat, power waste less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

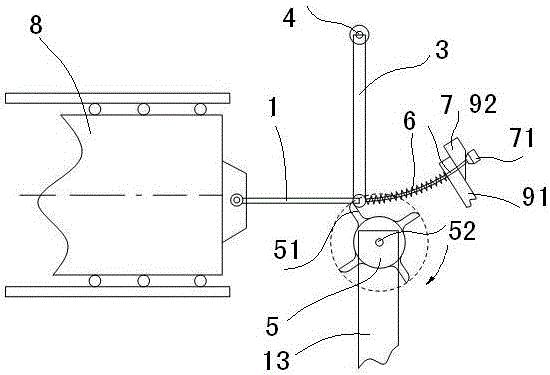

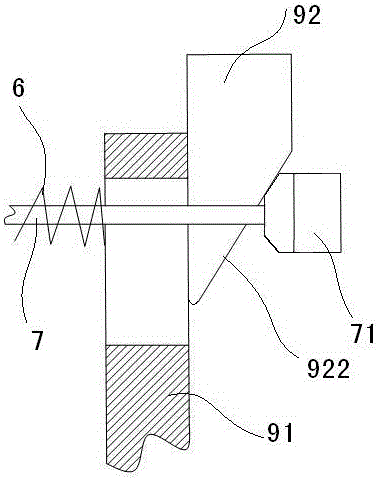

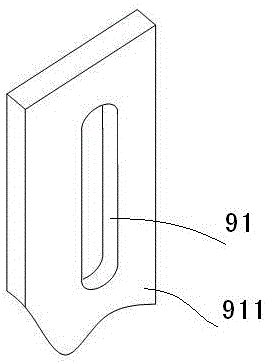

[0024] Embodiment 1: as figure 1 As shown, a device that converts circular rotation into linear reciprocating motion includes a connecting rod 1 whose back head is pinned to the slider. Rotationally connected, the upper end of the swing link 3 is rotatably connected with the pin rod 4 fixed on the machine base 13, and a 4-tooth dial 5 is arranged at the lower part of the front end of the connecting rod 1, and the dial teeth of the dial 5 51 and the pin shaft 2 can be pressed intermittently, the dial 5 is fixedly connected to the rotating shaft 52 connected to the machine base through bearings, and the rotating shaft 52 is connected to a transmission mechanism; the lower end of the swing rod 3 is pressed against one end of a compression spring 6 , The other end of compression spring 6 bears on the spring seat that is located on the clutch. The face of the shifting tooth 51 of the dial 5 facing the pin shaft 2 is a plane passing through the axis of the rotating shaft 52, and th...

Embodiment 2

[0029] Embodiment 2: The compression spring 6 of Embodiment 1 is removed, and the upper end of the swing rod 3 is fixedly connected with the weight rod 61. The weight rod 61 forms an angle of 70-90° with the swing rod 3 and forms a cantilever structure. The weight The tail end of the rod 61 is fixedly connected to the weight 62, the effect of the weight 62 on the swing rod 3 is equivalent to that of the compression spring 6 on the swing rod 3, see the attached Figure 6 .

[0030] The present invention is especially suitable for converting magnetic energy into mechanical rotation power. The magnetic energy power machine is a machine that uses a very small force to stimulate the release of magnetic energy and drive the power machine to run. The transmission process is: external force—magnetic power—mechanical energy; This device is through the process of external force - the conversion mechanism of this device - magnetic energy power - generator, that is, the circular rotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com