Energy-saving low-noise PLC control cabinet

A control cabinet and low-noise technology, which is applied in the field of energy-saving and low-noise PLC control cabinets, can solve problems such as poor anti-noise effect, achieve the effects of increasing resistance, convenient and labor-saving inflation process, and reducing air content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

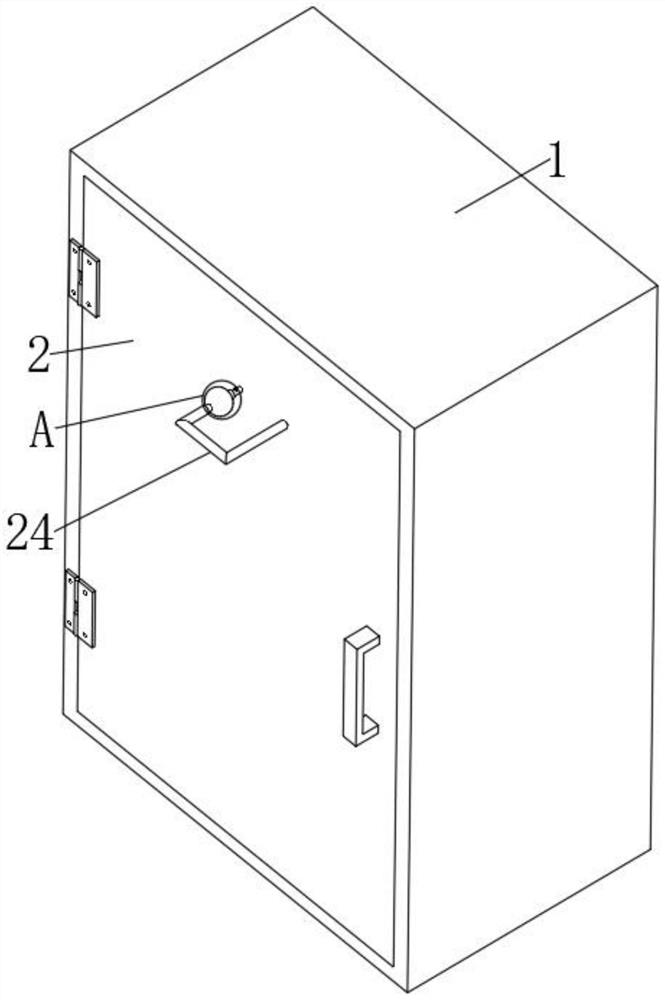

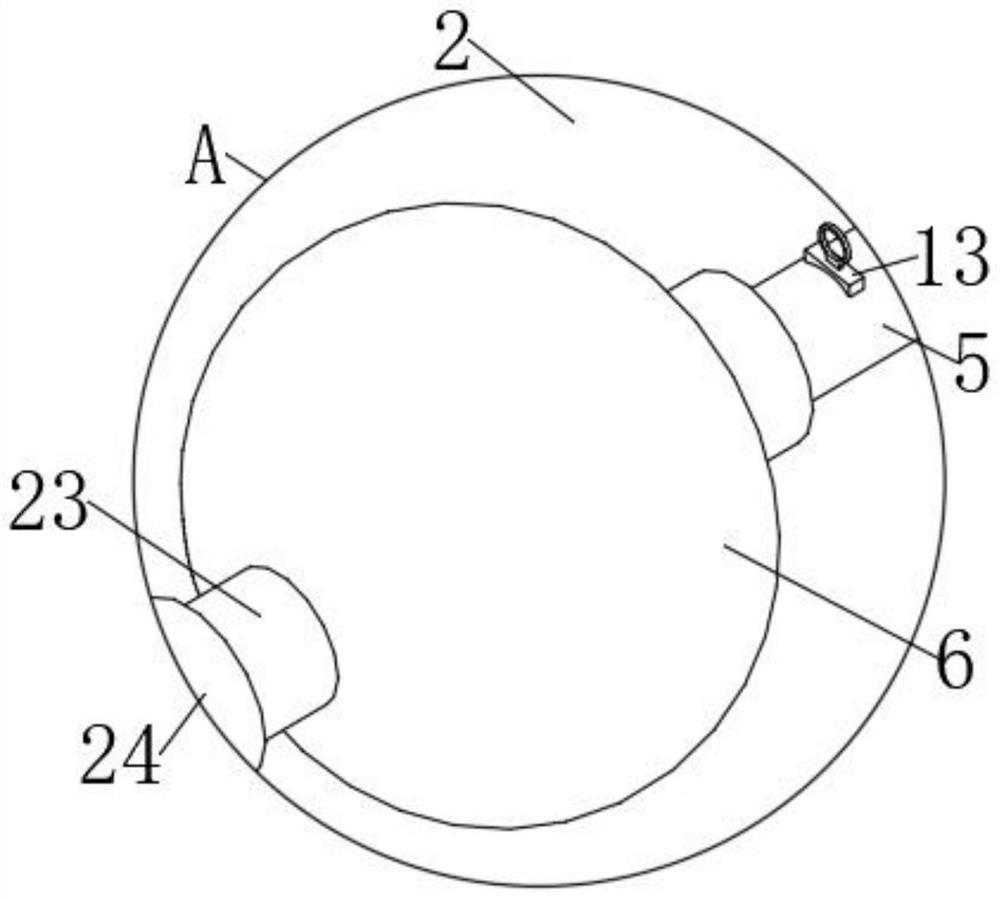

[0037] refer to Figure 1-7, an energy-saving and low-noise PLC control cabinet, comprising a cabinet body 1, a cabinet door 2 is hinged at the front end of the cabinet body 1, and the outer wall around the cabinet door 2 is provided with the same installation groove 3, and an inflatable hose 4 is bonded in the installation groove 3, The front end of the cabinet door 2 is fixed with a first branch pipe 5, the top of the first branch pipe 5 communicates with the inflation hose 4, the first branch pipe 5 is fixed with an anti-slip collar 22, and the front end of the first branch pipe 5 is covered with a balloon 6. The front end of the balloon 6 is bonded with a second branch pipe 23, and the front end of the second branch pipe 23 is connected with a connecting pipe 24, and the other side of the connecting pipe 24 is fixed through the cabinet door 2, and the inner walls on both sides of the second branch pipe 23 are provided with a second chute 25. A second slide block 26 is slid...

Embodiment 2

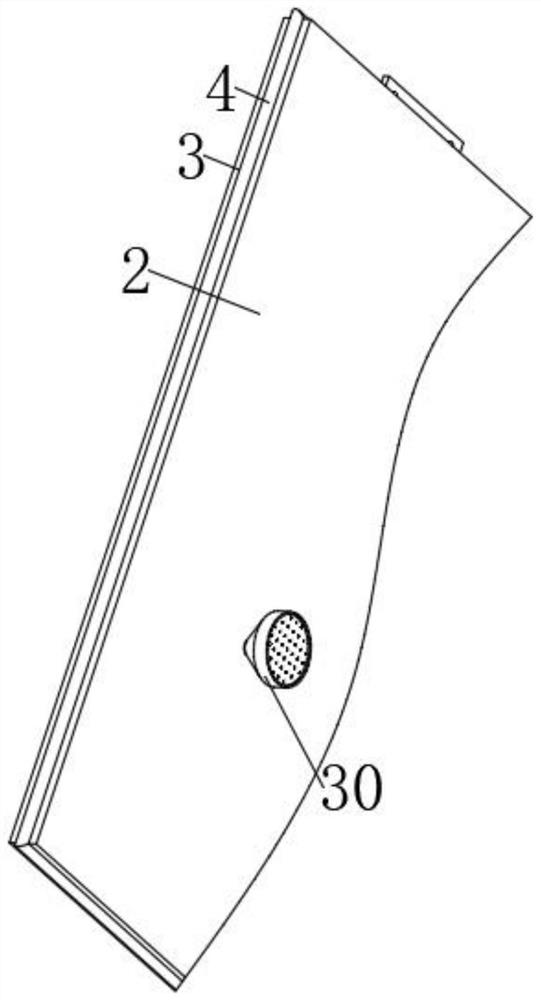

[0044] refer to Figure 8-12 , an energy-saving and low-noise PLC control cabinet, the rear end of the cabinet door 2 is fixed with a draft cover 30 by bolts, the draft cover 30 is arranged in a funnel shape, the draft cover 30 communicates with the connecting pipe 24, and the inner walls of the two sides of the draft cover 30 The same horizontal plate 31 is fixed between them by bolts. The rear end of the horizontal plate 31 runs through and is connected to the second shaft 32 through bearing rotation. The front end of the second shaft 32 is fixed with a fan blade 33 by bolts. There is a screen 46 .

[0045] Further, the inner wall on both sides of the air induction cover 30 is provided with a third chute 43, and the third chute 43 is slidably connected with a third slider 44, and the third slider 44 and the inner wall of the third chute 43 are connected by bolts. The same third spring 45 is fixed, the mesh plate 46 is fixed between the two third sliders 44 by bolts, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com